Karcher Système de recyclage des eaux usées WRP 16000 User Manual

Page 19

-

7

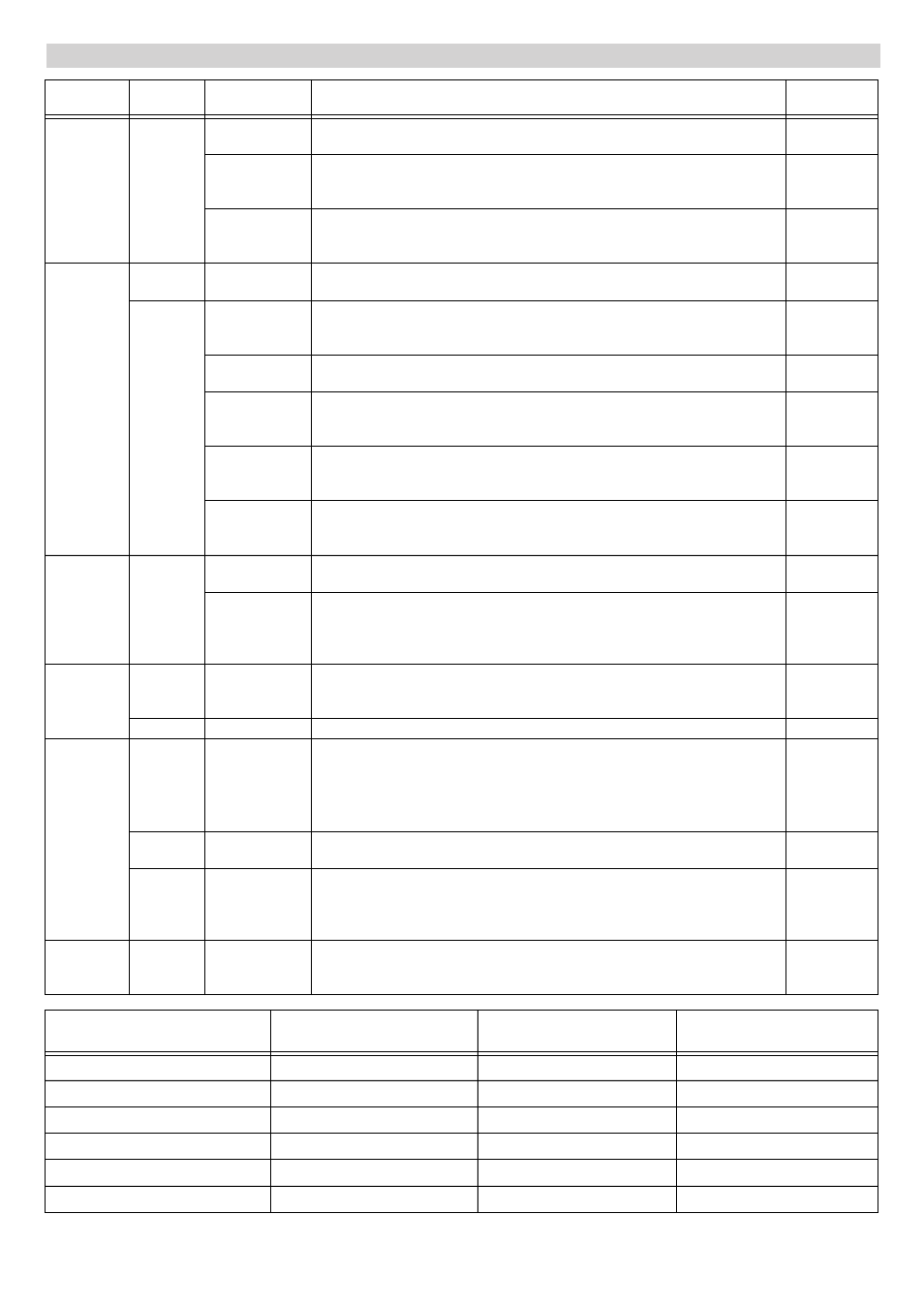

Maintenance schedule

Time

Activity

Assembly af-

fected

Performance

By whom

daily

opinion

Indicator lamps

"Error"

When this indicator lamp lights up, solve the problems according to instruc-

tions in the "Troubleshooting" section

Operator

Gravel filter

Recycled wa-

ter tanks

Check above-ground container for leakage.

Operator

Indicator lamp

"Fresh water

supply active"

Press the illuminated key "acknowledge message", find the cause for the

fresh water use and alleviate it.

Operator/

Customer

Service

weekly

Clean the

filter

Drain at wash-

ing place

Clean the dirt collection basket in the floor.

Operator

opinion

Gravel filter

Recycled wa-

ter tanks

Check inlets and outlets of the plant for clogging.

Operator

Recycling wa-

ter

Check recycled water for odour and turbidity. See section on "troubleshoot-

ing" for measures against poor quality of recycled water.

Operator

Detergent con-

centration in

recycled water

Check the detergent dose at the washing unit if there is too much foam for-

mation.

Operator

Gravel filter

Perform backwash, then check the filter pressure.

(If the capacity is too low, initiate a manual backwash and inform the after-

sales service if necessary.)

Operator

Recirculation

Ventilation

(Option)

Check circulation and membrane ventilator for proper function.

If the ventilation is running, bubbles are visible in the pump basin.

Operator

monthly

opinion

Swimmer

switch

Check the status of the float sensors; inform Customer Service, if required. Operator

Sludge collec-

tion, pump ba-

sin

After sludge has been collected, there should be no sludge in any of the ba-

sins. The sludge in the sludge collector should be maximum 1 m in height.

Check sludge level; pump out and dispose of the sludge, if required. Clean

the basin.

Operator

Quarterly

empty,

clean

Recycled wa-

ter tank

Pump basin

Empty and clean the recycled water tanks.

Clean float switch, submersible pump and membrane ventilator.

Operator

opinion

Unit:

Determine additional amount of water per vehicle washed.

Operator

half-yearly

Check the

gravel, re-

place if

required

Gravel filter

ƽ

Danger

Health hazard due to dust and microbial pollutants. Wear face masks and

gloves while changing the gravel.

Replace gravel if necessary; while doing so, clean upper and lower filter

sieve (rinse off with water).

Customer

Service

opinion

Backwashing

Does enough water flow from the pipe to the sludge trap during backwash-

ing? Check pressure.

Customer

Service

Check

through-

flow

quantity

Immersion

pump

The flow rate is correct if the water level in the processed water tank does

not fall below level S9 at the bottom when the washing unit is being operat-

ed.

Customer

Service

annual

empty,

clean

Sludge collec-

tion, pump ba-

sin

Empty, clean, and refill.

Operator

Float sensor level

Fill capacity recycled water 1

tank

Fill capacity recycled water

2 tanks

Fill capacity recycled water 3

tanks

S7 up

910 l

1,820 l

2,730 l

S7 bottom

890 l

1,780 l

2,670 l

S9 top

480 l

960

1,440 l

S9 bottom

460 l

920 l

1,380 l

S11 top

200 l

400 l

600 l

S11 bottom

180 l

360 l

540 l

19

EN