Troubleshooting guide – A.J. Antunes & Co ICE-H 9700922 User Manual

Page 2

A. J. ANTUNES & CO. www.ajantunes.com 180 Kehoe Blvd., Carol Stream, Illinois 60188

1-877-392-7836 Fax: 630-784-1000

Page 2 of 2

P/N 1011076 Rev. B 11/10

NOTE: Do NOT mounting the Chill iCE unit above the ice

machine’s sump water discharge outlet.

3. Use the included mounting straps to secure the Chill ICE

unit to either the ice bin or to the wall. Otherwise, place

the unit on the floor.

NOTE: health codes in some areas require the Chill iCE to

be at least 6 inches (15 cm) off the floor.

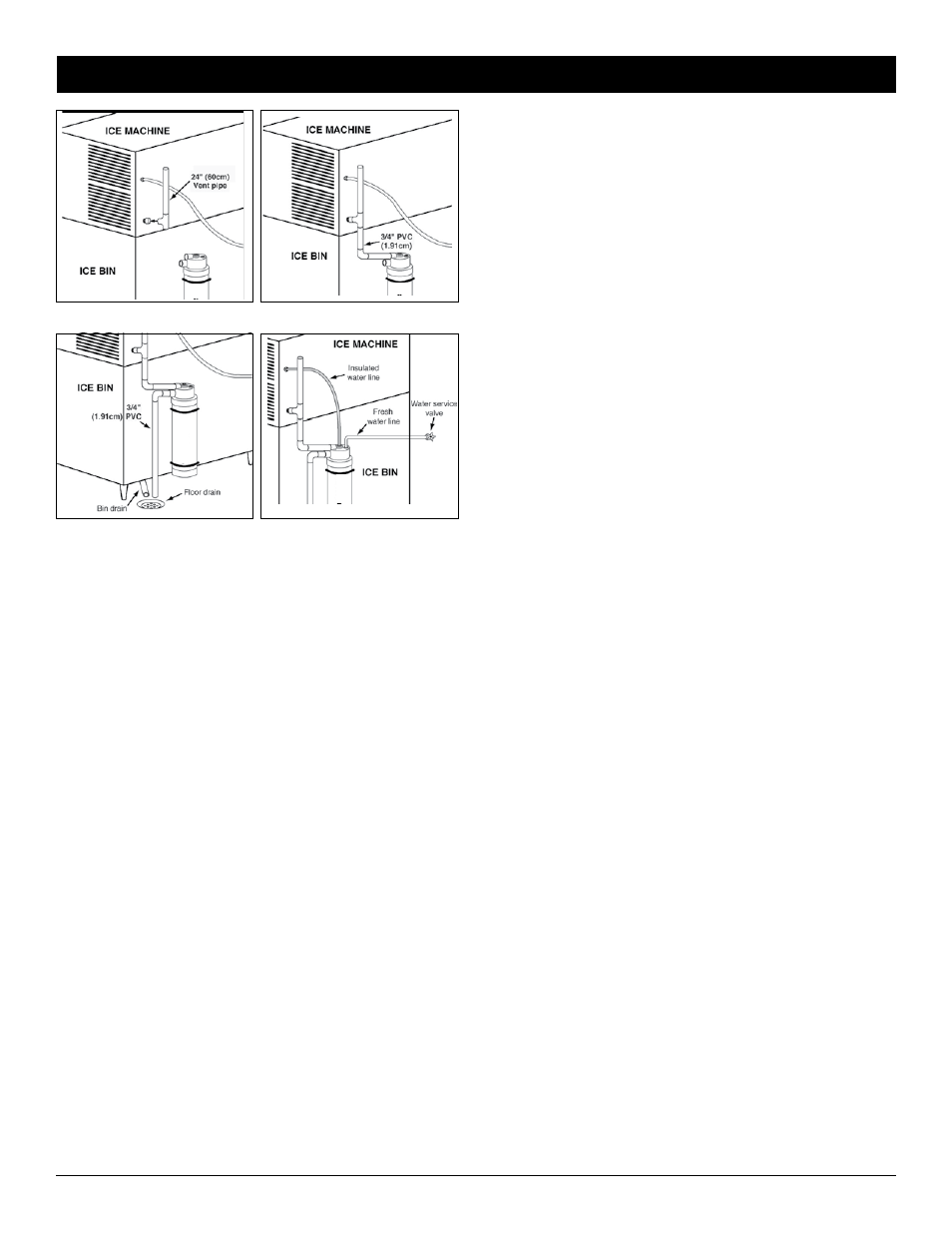

4. Use a T connector to install a vent pipe, or vacuum breaker,

at least 24 inches (60 cm) in length as close as possible to

the sump drain exiting the ice machine (Figure 4)

NOTE; The Chill iCE will NOT function properly without a

vent pipe.

5. Attach a PVC line from the vent pipe at the ice machine

drain outlet to the Sump Water Discharge Inlet on the

Chill ICE (connection #3). Be sure to plumb a vertical line

down from the ice machine drain and THEN a horizontal

line to the Chill ICE (Figure 5).

NOTE: Water will overflow into the ice bin if the line is

installed horizontally after existing the ice machine.

6. Connect a PVC line to the Sump Water Outlet on the Chill

ICE (connection #4) using a 90° fitting. Be sure to plumb

a vertical line down THEN a horizontal line to the floor

drain (Figure 6).

NOTE: Drain water will not flow properly if the line exiting

the Chill iCE is horizontal.

7. Carefully cut the existing fresh water line from the wall or

after the water filter. Leave enough tubing to reach from

the back of the ice machine to the top of the Chill ICE

unit.

Figure 4

Figure 6.

Figure 5.

Figure 7.

8. Insert insulated tubing into the Fresh Water Outlet on the

Chill ICE unit (connection #2).

NOTE: if you are unfamiliar with Speedfit® connectors,

review the Connections section on page 1.

9. Insert the tubing containing the fresh water source into the

Fresh Water Inlet on the Chill ICE (connection #1). If addi-

tional tubing is needed between the Chill ICE and the wall

outlet or water filter, be sure to connect the tubing with a

compression union (Figure 7).

10. Turn on the fresh water valve and check all connec-

tions for leaks. If you encounter any leaks, refer to the

Troubleshooting guide.

11. Check the water supply to the sump inside the ice

machine by depressing the float valve or by activating the

solenoid water valve.

12. Check the PVC drain lines for leaks by pouring water

through the vent pipe until it is seen exiting the Chill ICE unit

into the floor drain.

13. Turn on the ice machine. If you encounter any leaks, refer to

the Troubleshooting guide.

Troubleshooting Guide

iSSUE: The water lines are leaking at the Speedfit® fittings.

The tubing inserted in the fitting is not pushed in all the way

or the tubing end is out-of-round. Turn the water source off

to relieve line pressure, then remove tubing from the fitting

(see Connections section).

Inspect the end of the tubing to make certain there is a

clean square cut and the tubing is perfectly round. The

tubing should also be straight so it can be inserted com-

pletely (about 3/4” or 1.91 cm). Reinsert the tubing into

the fitting and press in firmly until the tubing “bottoms”

securely. Turn the water valve on and check again for

leaks.

iSSUE: When the ice machine is turned on, there isn’t any

water entering the sump to make ice.

Sometimes when the existing fresh water lines are cut

and bent to be inserted into the Chill ICE, some particu-

late matter can be broken loose and cause the water

supply within the ice machine to become clogged. Turn

the water source valve off. Inspect all needle valves, filter

screens, and any other water supply valves inside the

machine. Remove any debris found, then turn the water

source on and depress the float switch in the sump to

make certain the restriction was removed.

iSSUE: When the ice machine is running, there is water

overflowing out of the top of the vent pipe and the Chill iCE

seems to be clogged.

Either extend the height of the vent pipe if space per-

mits or use a larger diameter of PVC pipe in the existing

space. Both will allow for a greater volume of water to

rise in the vent pipe to overcome the air lock in the drain

system.