Vertical contact toaster, Troubleshooting (continued) – A.J. Antunes & Co VCT-2000 9210410 User Manual

Page 18

VERTICAL CONTACT TOASTER

18

P/N 1010840 Rev. M 07/14

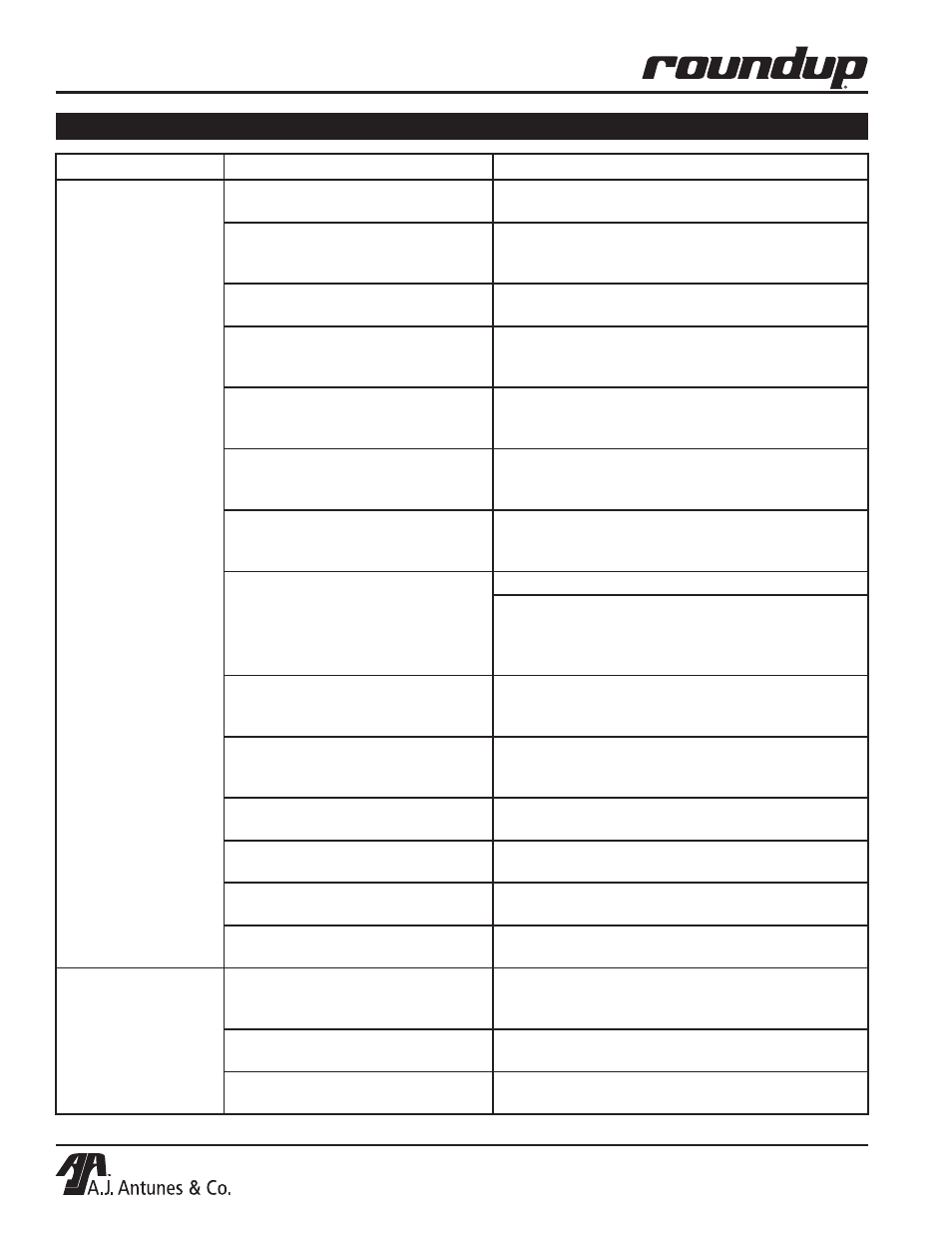

TROUBLESHOOTING (continued)

Problem

Possible Cause

Corrective Action

Crowns and/or Heels

must be forced into

the toaster.

Buns

sticking and burn-

ing.

Belt Wraps not being cleaned prop-

erly.

Clean Belt Wraps as described in the Maintenance

section of this manual.

Conveyor Belt Wraps are not tacky/

sticky (replace every 3–6 months).

Clean Belt Wraps. If the Belt Wraps are too worn,

replace them as described in the maintenance

section of this manual.

Belt Wraps are dirty, worn, or dam-

aged (replace every 3–6 months).

Clean or replace Belt Wraps as described in the

Maintenance section of this manual.

Release Sheet is not being cleaned

properly.

Clean both sides of the black and silver Release

Sheet as described in the Maintenance section of

this manual.

Release Sheet is not being reversed

as required.

Reverse the Release Sheet or replace Release

Sheet as described in the Maintenance section of

this manual.

Release Sheet is dirty, worn, or

damaged (replace every 4–6

weeks).

Clean or replace Release Sheet as described in the

Maintenance section of this manual.

Conveyor Belt Chains are skipping

on Sprockets.

Measure and adjust the Conveyor Belt Chains as

described in the Maintenance section of this

manual.

Conveyor Safety Interlock Switch

is not being activated by the Heat

Shield.

Heat Shield is ajar. Reposition Heat Shield.

Heat Shield is damaged. Replace if necessary. If

the Conveyor Safety Interlock Switch is damaged,

contact your maintenance person or Authorized

Service Agency for service.

Belt Wraps slipping over Conveyor

Belt Chains.

Remove Belt Wraps and clean the Conveyor Belt

Chain links and Belt Wraps as described in the

Maintenance section of this manual.

Roller Tensioner(s) damaged or

missing.

Reinstall or replace Roller Tensioner(s) as described

in the Maintenance section of this

manual.

Drive Motor stalls intermittently.

Contact your maintenance person or an Authorized

Service Agency for service.

Compression Settings are incorrect. Use the recommended settings. Set Heel to 2 and

Crown to 6.

Buns are not inserted into the toast-

er properly.

Buns must be inserted with the cut sides facing

each other on the correct Heel or Crown side.

Non-OEM or damaged Belt Wraps

used.

Replace with OEM Belt Wraps (P/N 7000416).

New Conveyor Belt

Wraps do not fit.

Compression Settings are incorrect. Set Compression Knobs to 6 and 6 when replac-

ing Belt Wraps or when adjusting Conveyor Belt

Chains.

Belt Wraps not installed correctly.

Install Belt Wraps inside the Yellow Support Rods

with the “zipper flap” exposed and hanging down.

Non-OEM or damaged Belt Wraps

used.

Replace with OEM Belt Wraps (P/N 7000416).