PerTronix JBA Exhaust 40-1513 User Manual

Installation instructions, T o st art, Part s list

INSTALLATION INSTRUCTIONS

1999-2000 JEEP GRAND CHEROKEE

4.0L-4.7L 2/4WD

T OOLS RECOMMENDED:

T O ST ART :

3/8'' Ratchet

15mm socket

9/16'' socket

Hack saw or reciprocating saw

Rubber mallet

Anti Seize

2. Disconnect negative battery cable and

allow vehicle exhaust to cool.

3. With vehicle raised and properly sup-

ported, support muffler and cut off tail

pipe 2'' behind rear of muffler.

4. Slip rear tail pipe hanger from rubber

grommet, and remove tail pipe from rear of

vehicle.

INSTALLATION INSTRUCTIONS

1999-2000 JEEP GRAND CHEROKEE

4.0L-4.7L 2/4WD

T OOLS RECOMMENDED:

T O ST ART :

3/8'' Ratchet

15mm socket

9/16'' socket

Hack saw or reciprocating saw

Rubber mallet

Anti Seize

2. Disconnect negative battery cable and

allow vehicle exhaust to cool.

3. With vehicle raised and properly sup-

ported, support muffler and cut off tail

pipe 2'' behind rear of muffler.

4. Slip rear tail pipe hanger from rubber

grommet, and remove tail pipe from rear of

vehicle.

INSTALLATION INSTRUCTIONS

1999-2000 JEEP GRAND CHEROKEE

4.0L-4.7L 2/4WD

T OOLS RECOMMENDED:

T O ST ART :

3/8'' Ratchet

15mm socket

9/16'' socket

Hack saw or reciprocating saw

Rubber mallet

Anti Seize

2. Disconnect negative battery cable and

allow vehicle exhaust to cool.

3. With vehicle raised and properly sup-

ported, support muffler and cut off tail

pipe 2'' behind rear of muffler.

4. Slip rear tail pipe hanger from rubber

grommet, and remove tail pipe from rear of

vehicle.

INSTALLATION INSTRUCTIONS

1999-2000 JEEP GRAND CHEROKEE

4.0L-4.7L 2/4WD

T OOLS RECOMMENDED:

T O ST ART :

3/8'' Ratchet

15mm socket

9/16'' socket

Hack saw or reciprocating saw

Rubber mallet

Anti Seize

2. Disconnect negative battery cable and

allow vehicle exhaust to cool.

3. With vehicle raised and properly sup-

ported, support muffler and cut off tail

pipe 2'' behind rear of muffler.

4. Slip rear tail pipe hanger from rubber

grommet, and remove tail pipe from rear of

vehicle.

5. With muffler properly supported, loosen

front muffler clamp at slip joint using a

15mm socket.

14. Rotate tail pipe to desired position,

checking tip for proper clearance on

rear bumper.

1. Remove and inventory new Evol™

exhaust.

6. Using some form of heat and force

remove muffler assembly without damag-

ing catalytic converter pipe.

17. Check exhaust kit for proper clear-

ances, and tack weld all slip joints in

three spots.

18. Using a soft cloth, remove all prints

from turnout tip.

19. Lower vehicle and reattach the

negative battery cable.

NOTES:

1.

If anti seize is not used on threads of

clamps before tightening, the nut's will

gall, and clamp rod will break.

11. Starting from rear of vehicle, install tail

pipe (C) slipping rear tail pipe hanger into

rubber grommet.

12. Install tail pipe (C) into rear muffler

slip joint making sure it is bottomed out.

7. Install Evol™ head pipe (A) aligning

notch with pin.

NOTE:

You may have to

tap on with rubber mallet.

8. Install 2 1/4'' clamp (D) over head pipe

slip joint, and tighten completely using a

9/16'' socket.

NOTE:

USE ANTI SEIZE

ON THREADS. See notes #1.

5. With muffler properly supported, loosen

front muffler clamp at slip joint using a

15mm socket.

14. Rotate tail pipe to desired position,

checking tip for proper clearance on

rear bumper.

1. Remove and inventory new Evol™

exhaust.

6. Using some form of heat and force

remove muffler assembly without damag-

ing catalytic converter pipe.

17. Check exhaust kit for proper clear-

ances, and tack weld all slip joints in

three spots.

18. Using a soft cloth, remove all prints

from turnout tip.

19. Lower vehicle and reattach the

negative battery cable.

NOTES:

1.

If anti seize is not used on threads of

clamps before tightening, the nut's will

gall, and clamp rod will break.

11. Starting from rear of vehicle, install tail

pipe (C) slipping rear tail pipe hanger into

rubber grommet.

12. Install tail pipe (C) into rear muffler

slip joint making sure it is bottomed out.

7. Install Evol™ head pipe (A) aligning

notch with pin.

NOTE:

You may have to

tap on with rubber mallet.

8. Inst

slip joint, and tighten completely using a

9/16'' socket.

NOTE:

USE ANTI SEIZE

ON THREADS. See notes #1.

5. With muffler properly supported, loosen

front muffler clamp at slip joint using a

15mm socket.

14. Rotate tail pipe to desired position,

checking tip for proper clearance on

rear bumper.

1. Remove and inventory new Evol™

exhaust.

6. Using some form of heat and force

remove muffler assembly without damag-

ing catalytic converter pipe.

17. Check exhaust kit for proper clear-

ances, and tack weld all slip joints in

three spots.

18. Using a soft cloth, remove all prints

from turnout tip.

19. Lower vehicle and reattach the

negative battery cable.

NOTES:

1.

If anti seize is not used on threads of

clamps before tightening, the nut's will

gall, and clamp rod will break.

11. Starting from rear of vehicle, install tail

pipe (C) slipping rear tail pipe hanger into

rubber grommet.

12. Install tail pipe (C) into rear muffler

slip joint making sure it is bottomed out.

7. Install Evol™ head pipe (A) aligning

notch with pin.

NOTE:

You may have to

tap on with rubber mallet.

8. Inst

slip joint, and tighten completely using a

9/16'' socket.

NOTE:

USE ANTI SEIZE

ON THREADS. See notes #1.

5. With muffler properly supported, loosen

front muffler clamp at slip joint using a

15mm socket.

14. Rotate tail pipe to desired position,

checking tip for proper clearance on

rear bumper.

1. Remove and inventory new Evol™

exhaust.

6. Using some form of heat and force

remove muffler assembly without damag-

ing catalytic converter pipe.

17. Check exhaust kit for proper clear-

ances, and tack weld all slip joints in

three spots.

18. Using a soft cloth, remove all prints

from turnout tip.

19. Lower vehicle and reattach the

negative battery cable.

NOTES:

1.

If anti seize is not used on threads of

clamps before tightening, the nut's will

gall, and clamp rod will break.

11. Starting from rear of vehicle, install tail

pipe (C) slipping rear tail pipe hanger into

rubber grommet.

12. Install tail pipe (C) into rear muffler

slip joint making sure it is bottomed out.

7. Install Evol™ head pipe (A) aligning

notch with pin.

NOTE:

You may have to

tap on with rubber mallet.

8. Inst

slip joint, and tighten completely using a

9/16'' socket.

NOTE:

USE ANTI SEIZE

ON THREADS. See notes #1.

9. Install muffler (B) on head pipe (A)

making sure slip joint is bottomed out,

and muffler is level and aligned properly.

9. Install muffler (B) on head pipe (A)

making sure slip joint is bottomed out,

and muffler is level and aligned properly.

9. Install muffler (B) on head pipe (A)

making sure slip joint is bottomed out,

and muffler is level and aligned properly.

9. Install muffler (B) on head pipe (A)

making sure slip joint is bottomed out,

and muffler is level and aligned properly.

10. Install and position 2 1/2''clamp (E)

over front muffler slip joint and tighten

completely using a 9/16''deep wall socket.

NOTE:

USE ANTI SEIZE ON THREADS

See notes #1

10. Inst

over front muffler slip joint and tighten

completely using a 9/16''deep wall socket.

NOTE:

USE ANTI SEIZE ON THREADS

See notes #1

10. Inst

over front muffler slip joint and tighten

completely using a 9/16''deep wall socket.

NOTE:

USE ANTI SEIZE ON THREADS

See notes #1

10. Inst

over front muffler slip joint and tighten

completely using a 9/16''deep wall socket.

NOTE:

USE ANTI SEIZE ON THREADS

See notes #1

13. Install and position clamp (F) over

rear muffler slip joint and tighten slightly at

this time using a 9/16'' deep wall socket.

NOTE:

USE ANTI SEIZE ON THREADS

See notes #1

13. Install and position clamp (F) over

rear muffler slip joint and tighten slightly at

this time using a 9/16'' deep wall socket.

NOTE:

USE ANTI SEIZE ON THREADS

See notes #1

13. Install and position clamp (F) over

rear muffler slip joint and tighten slightly at

this time using a 9/16'' deep wall socket.

NOTE:

USE ANTI SEIZE ON THREADS

See notes #1

13. Install and position clamp (F) over

rear muffler slip joint and tighten slightly at

this time using a 9/16'' deep wall socket.

NOTE:

USE ANTI SEIZE ON THREADS

See notes #1

16. With tail pipe in proper position tighten

clamp (F) completely using a 9/16'' deep

wall socket.

NOTE:

USE ANTI SEIZE ON

THREADS See notes #1

16. With tail pipe in proper position tighten

clamp (F) completely using a 9/16'' deep

wall socket.

NOTE:

USE ANTI SEIZE ON

THREADS See notes #1

16. With tail pipe in proper position tighten

clamp (F) completely using a 9/16'' deep

wall socket.

NOTE:

USE ANTI SEIZE ON

THREADS See notes #1

16. With tail pipe in proper position tighten

clamp (F) completely using a 9/16'' deep

wall socket.

NOTE:

USE ANTI SEIZE ON

THREADS See notes #1

We recommend t aking the truck to a muffler shop and having all slip connections t

ack welded.

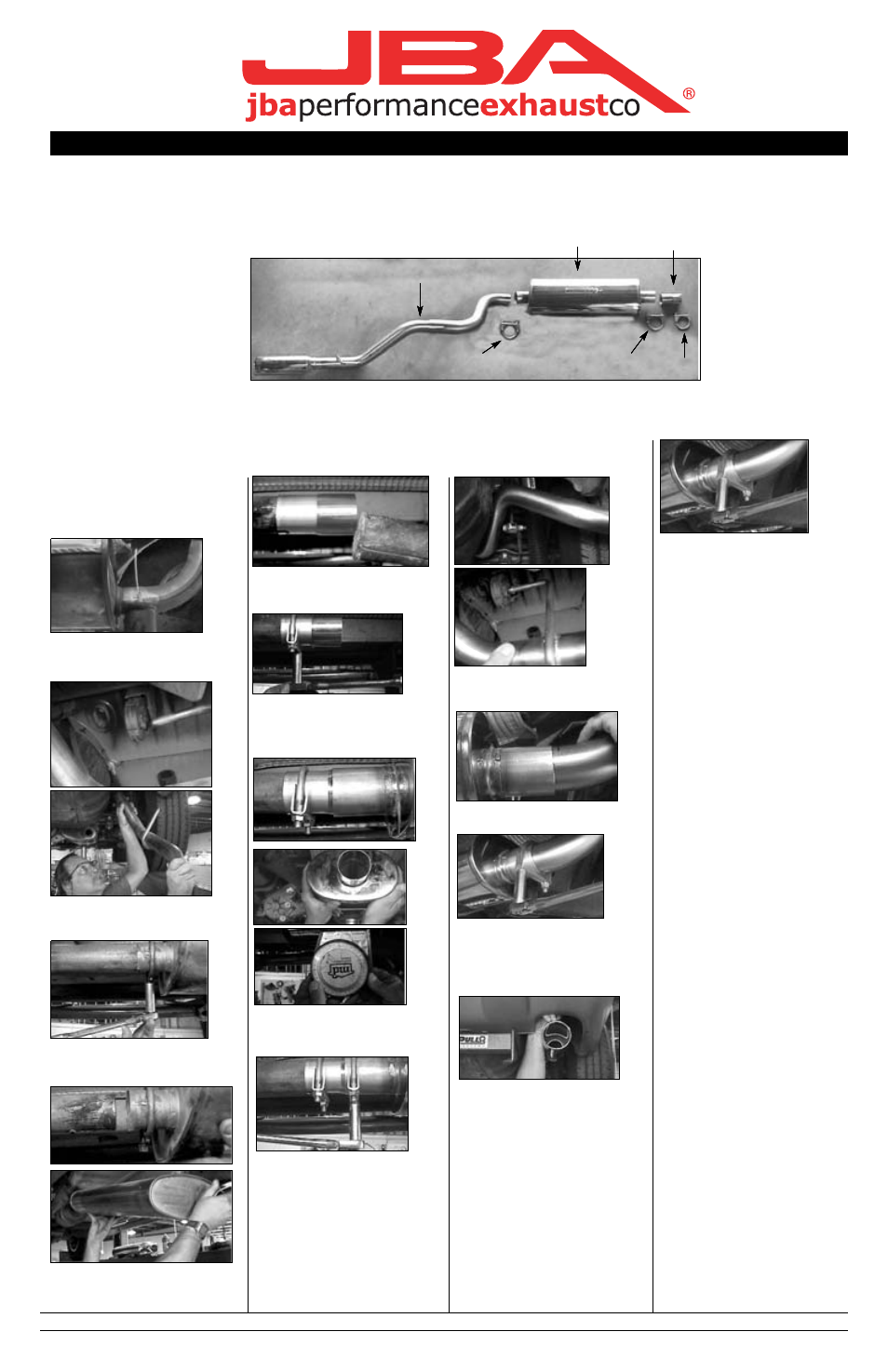

Part s List

A. Head pipe

1

B. Muffler, oval 24" - 2-1/2" C/C

1

C. Tail pipe w/tip

1

D. 2-1/4" clamp

1

E. 2-1/2" clamp

1

F. 2-1/2" clamp

1

**Installation recommendation:

JBA recommends in most cases that the vehicle be t

aken to a reput able exhaust shop.

17226

We recommend t aking the truck to a muffler shop and having all slip connections t

ack welded.

Part s List

A. Head pipe

1

B. Muffler

1

C. Tail pipe w/tip

1

D.

1

E.

1

F.

1

**Installation recommendation:

aken to a reput able exhaust shop.

17226

We recommend t aking the truck to a muffler shop and having all slip connections t

ack welded.

Part s List

A. Head pipe

1

B. Muffler

1

C. Tail pipe w/tip

1

D.

1

E.

1

F.

1

**Installation recommendation:

aken to a reput able exhaust shop.

17226

We recommend t aking the truck to a muffler shop and having all slip connections t

ack welded.

Part s List

A. Head pipe

1

B. Muffler

1

C. Tail pipe w/tip

1

D.

1

E.

1

F.

1

**Installation recommendation:

aken to a reput able exhaust shop.

17226

B

A

D

E

C

F

B

A

D

E

C

F

B

A

D

E

C

F

B

A

D

E

C

F

40-1513