PerTronix JBA Exhaust 40-1508 User Manual

Installation instructions, T o st art, Part s list

INSTALLATION INSTRUCTIONS

1998-00 Dodge Ram 1500/2500 All

T OOLS RECOMMENDED:

T O ST ART :

9/16 deep socket

ratchet

10mm wrench

15mm deep socket

prybar

rubber mallet

spray lubricant or penetrating oil

anti-seize

reciprocating saw or hack saw

pair of channel lock pliers

2. Disconnect negative battery cable and

allow vehicle exhaust to cool.

3. With vehicle raised and properly sup-

ported, using a reciprocating saw or hack

saw, cut tail pipe approximately 1" behind

rear muffler clamp and in front of tail pipe

hanger.

4. Spray lubricant on lower holes of front

and rear tail pipe hanger rubber grommets.

INSTALLATION INSTRUCTIONS

1998-00 Dodge Ram 1500/2500 All

T OOLS RECOMMENDED:

T O ST ART :

9/16 deep socket

ratchet

10mm wrench

15mm deep socket

prybar

rubber mallet

spray lubricant or penetrating oil

anti-seize

reciprocating saw or hack saw

pair of channel lock pliers

2. Disconnect negative battery cable and

allow vehicle exhaust to cool.

3. With vehicle raised and properly sup-

ported, using a reciprocating saw or hack

saw, cut tail pipe approximately 1" behind

rear muffler clamp and in front of tail pipe

hanger.

4. Spray lubricant on lower holes of front

and rear tail pipe hanger rubber grommets.

INSTALLATION INSTRUCTIONS

1998-00 Dodge Ram 1500/2500 All

T OOLS RECOMMENDED:

T O ST ART :

9/16 deep socket

ratchet

10mm wrench

15mm deep socket

prybar

rubber mallet

spray lubricant or penetrating oil

anti-seize

reciprocating saw or hack saw

pair of channel lock pliers

2. Disconnect negative battery cable and

allow vehicle exhaust to cool.

3. With vehicle raised and properly sup-

ported, using a reciprocating saw or hack

saw, cut tail pipe approximately 1" behind

rear muffler clamp and in front of tail pipe

hanger.

4. Spray lubricant on lower holes of front

and rear tail pipe hanger rubber grommets.

INSTALLATION INSTRUCTIONS

1998-00 Dodge Ram 1500/2500 All

T OOLS RECOMMENDED:

T O ST ART :

9/16 deep socket

ratchet

10mm wrench

15mm deep socket

prybar

rubber mallet

spray lubricant or penetrating oil

anti-seize

reciprocating saw or hack saw

pair of channel lock pliers

2. Disconnect negative battery cable and

allow vehicle exhaust to cool.

3. With vehicle raised and properly sup-

ported, using a reciprocating saw or hack

saw, cut tail pipe approximately 1" behind

rear muffler clamp and in front of tail pipe

hanger.

4. Spray lubricant on lower holes of front

and rear tail pipe hanger rubber grommets.

5. Using a pair of channel lock pliers,

remove hanger rods from bottom holes of

two rear tail pipe rubber grommets.

10. Using some form of heat and force,

disengage and remove muffler without

damaging head pipe.

17. Install turn out clamp/hanger (H)

over end of tail pipe (C) and into rubber

grommet.

1. Remove and inventory new JBA

exhaust.

11. Align notch with locating pin and install

head pipe (A) using the 2-1/2" clamp (E).

Tighten completely with 9/16" deep wall

socket.

Note:

Use anti-seize on threads.

6. Using a pair of channel lock pliers,

remove front tail pipe hanger rod from

bottom hole in rubber grommet.

7. Remove tail pipe from rear of vehicle.

13. Using the 3" clamp (F), tighten clamp

completely using 9/16"deep wall socket.

20. After installation, it is recommended

that all clamps be retightened and joints

tack welded in 3 spots.

21. Using a soft cloth, remove all prints

from turnout tip.

22. Lower vehicle and reattach the nega-

tive battery cable.

NOTES:

1) It may be necessary to loosen and

realign the spare tire for proper clear-

ance.

2) All exhaust systems will expand about

1î rearward when exhaust temperature

start to rise.

3) Use Anti-seize on threads of clamps.

14. Install tail pipe (C) from rear of vehi-

cle with double hanger towards muffler.

15. Install front two hangers on tail pipe

(C) into lower holes of rubber grommet.

16. Install rear tail pipe hanger into rubber

grommet. Align tail pipe and tighten 3"

clamp (G) completely.

Note:

Use anti-

seize on threads.

8. Spray penetrating oil on threads of front

muffler clamp.

9. Using a 15mm socket, remove front

muffler clamp.

5. Using a pair of channel lock pliers,

remove hanger rods from bottom holes of

two rear tail pipe rubber grommets.

10. Using some form of heat and force,

disengage and remove muffler without

damaging head pipe.

17. Install turn out clamp/hanger (H)

over end of tail pipe (C) and into rubber

grommet.

1. Remove and inventory new JBA

exhaust.

11. Align notch with locating pin and install

head pipe (A) using the 2-1/2" clamp (E).

Tighten completely with 9/16" deep wall

socket.

Note:

Use anti-seize on threads.

6. Using a pair of channel lock pliers,

remove front tail pipe hanger rod from

bottom hole in rubber grommet.

7. Remove tail pipe from rear of vehicle.

13. Using the 3" clamp (F), tighten clamp

completely using 9/16"deep wall socket.

20. After installation, it is recommended

that all clamps be retightened and joints

tack welded in 3 spots.

21. Using a soft cloth, remove all prints

from turnout tip.

22. Lower vehicle and reattach the nega-

tive battery cable.

NOTES:

1) It may be necessary to loosen and

realign the spare tire for proper clear-

ance.

2) All exhaust systems will expand about

1î rearward when exhaust temperature

start to rise.

3) Use Anti-seize on threads of clamps.

14. Install tail pipe (C) from rear of vehi-

cle with double hanger towards muffler.

15. Install front two hangers on tail pipe

(C) into lower holes of rubber grommet.

16. Install rear tail pipe hanger into rubber

grommet. Align tail pipe and tighten 3"

clamp (G) completely.

Note:

Use anti-

seize on threads.

8. Spray penetrating oil on threads of front

muffler clamp.

9. Using a 15mm socket, remove front

muffler clamp.

5. Using a pair of channel lock pliers,

remove hanger rods from bottom holes of

two rear tail pipe rubber grommets.

10. Using some form of heat and force,

disengage and remove muffler without

damaging head pipe.

17. Install turn out clamp/hanger (H)

over end of tail pipe (C) and into rubber

grommet.

1. Remove and inventory new JBA

exhaust.

11. Align notch with locating pin and install

head pipe (A) using the 2-1/2" clamp (E).

Tighten completely with 9/16" deep wall

socket.

Note:

Use anti-seize on threads.

6. Using a pair of channel lock pliers,

remove front tail pipe hanger rod from

bottom hole in rubber grommet.

7. Remove tail pipe from rear of vehicle.

13. Using the 3" clamp (F), tighten clamp

completely using 9/16"deep wall socket.

20. After installation, it is recommended

that all clamps be retightened and joints

tack welded in 3 spots.

21. Using a soft cloth, remove all prints

from turnout tip.

22. Lower vehicle and reattach the nega-

tive battery cable.

NOTES:

1) It may be necessary to loosen and

realign the spare tire for proper clear-

ance.

2) All exhaust systems will expand about

1î rearward when exhaust temperature

start to rise.

3) Use Anti-seize on threads of clamps.

14. Install tail pipe (C) from rear of vehi-

cle with double hanger towards muffler.

15. Install front two hangers on tail pipe

(C) into lower holes of rubber grommet.

16. Install rear tail pipe hanger into rubber

grommet. Align tail pipe and tighten 3"

clamp (G) completely.

Note:

Use anti-

seize on threads.

8. Spray penetrating oil on threads of front

muffler clamp.

9. Using a 15mm socket, remove front

muffler clamp.

5. Using a pair of channel lock pliers,

remove hanger rods from bottom holes of

two rear tail pipe rubber grommets.

10. Using some form of heat and force,

disengage and remove muffler without

damaging head pipe.

17. Install turn out clamp/hanger (H)

over end of tail pipe (C) and into rubber

grommet.

1. Remove and inventory new JBA

exhaust.

11. Align notch with locating pin and install

head pipe (A) using the 2-1/2" clamp (E).

Tighten completely with 9/16" deep wall

socket.

Note:

Use anti-seize on threads.

6. Using a pair of channel lock pliers,

remove front tail pipe hanger rod from

bottom hole in rubber grommet.

7. Remove tail pipe from rear of vehicle.

13. Using the 3" clamp (F), tighten clamp

completely using 9/16"deep wall socket.

20. After installation, it is recommended

that all clamps be retightened and joints

tack welded in 3 spots.

21. Using a soft cloth, remove all prints

from turnout tip.

22. Lower vehicle and reattach the nega-

tive battery cable.

NOTES:

1) It may be necessary to loosen and

realign the spare tire for proper clear-

ance.

2) All exhaust systems will expand about

1î rearward when exhaust temperature

start to rise.

3) Use Anti-seize on threads of clamps.

14. Install tail pipe (C) from rear of vehi-

cle with double hanger towards muffler.

15. Install front two hangers on tail pipe

(C) into lower holes of rubber grommet.

16. Install rear tail pipe hanger into rubber

grommet. Align tail pipe and tighten 3"

clamp (G) completely.

Note:

Use anti-

seize on threads.

8. Spray penetrating oil on threads of front

muffler clamp.

9. Using a 15mm socket, remove front

muffler clamp.

12. With JBA logo facing rear of vehicle,

install muffler (B) over head pipe (A) mak-

ing sure muffler bottoms out on slip joint.

12. With JBA logo facing rear of vehicle,

install muffler (B) over head pipe (A) mak-

ing sure muffler bottoms out on slip joint.

12. With JBA logo facing rear of vehicle,

install muffler (B) over head pipe (A) mak-

ing sure muffler bottoms out on slip joint.

12. With JBA logo facing rear of vehicle,

install muffler (B) over head pipe (A) mak-

ing sure muffler bottoms out on slip joint.

18. Install turn out (D) to end of tail pipe

(C) rotate to desired position approx. 1"

from body.

18. Install turn out (D) to end of tail pipe

(C) rotate to desired position approx. 1"

from body.

18. Install turn out (D) to end of tail pipe

(C) rotate to desired position approx. 1"

from body.

18. Install turn out (D) to end of tail pipe

(C) rotate to desired position approx. 1"

from body.

19. Tighten clamp/hanger (H) completely

using 9/16" deep wall socket.

Note:

Use anti-seize on threads.

19. Tighten clamp/hanger (H) completely

using 9/16" deep wall socket.

Note:

Use anti-seize on threads.

19. Tighten clamp/hanger (H) completely

using 9/16" deep wall socket.

Note:

Use anti-seize on threads.

19. Tighten clamp/hanger (H) completely

using 9/16" deep wall socket.

Note:

Use anti-seize on threads.

We recommend taking the truck to a muffler shop and having all slip connections tack welded

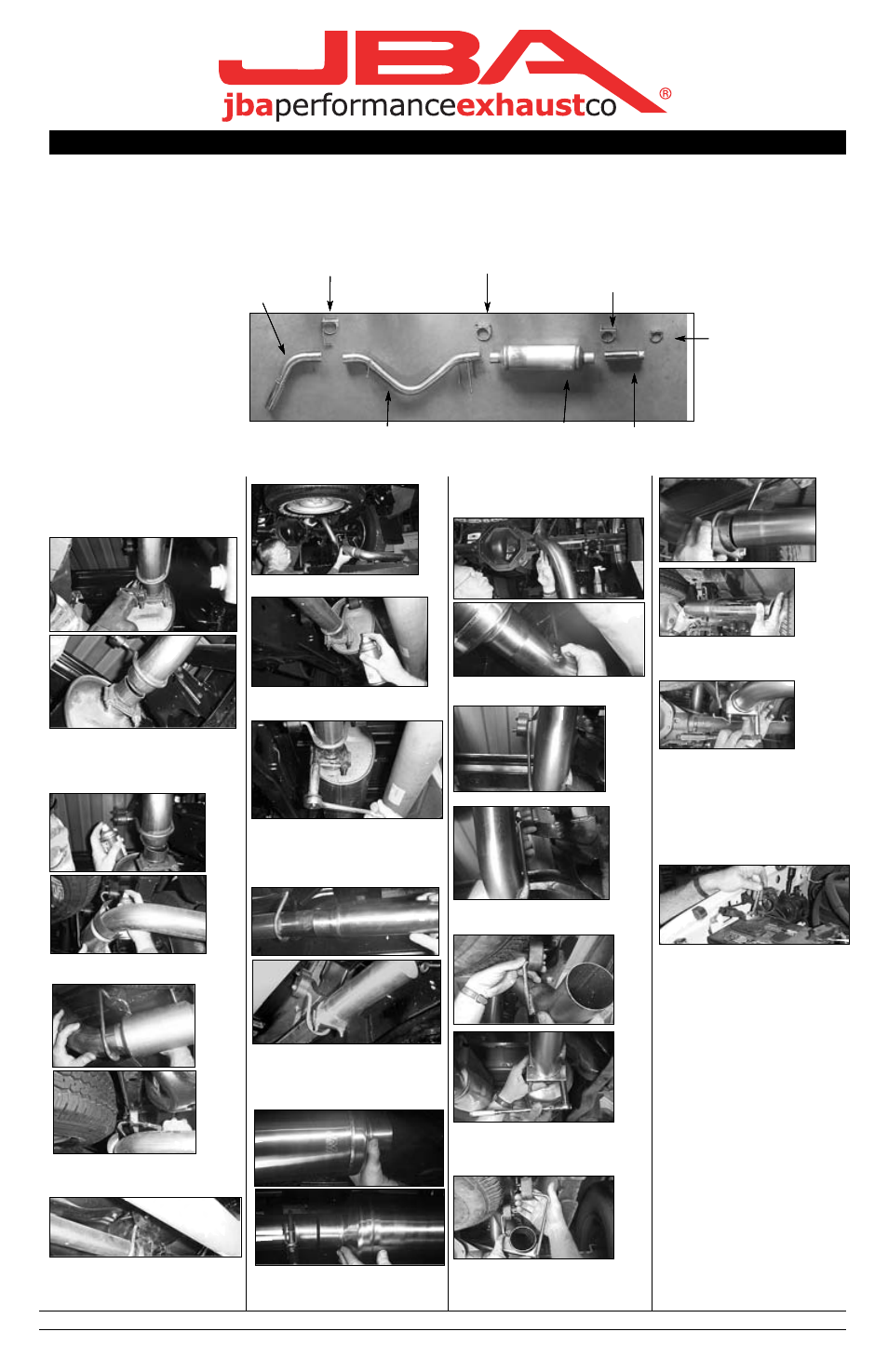

Part s List

A. Head pipe

1

B. Muffler, 24"

1

C. Tail pipe

1

D. Turn out

1

E. 2-1/2" clamp

1

F. 3" clamp

1

G. 3" clamp

1

H. Tail pipe clamp/hanger

1

**Inst allation recommendation:

JBA recommends in most cases that the vehicle be taken to a reputable exhaust shop.

17039a

4-25-00

We recommend taking the truck to a muffler shop and having all slip connections tack welded

Part s List

A. Head pipe

1

B. Muffler, 24"

1

C. Tail pipe

1

D. Turn out

1

E. 2-1/2" clamp

1

F. 3" clamp

1

G. 3" clamp

1

H. Tail pipe clamp/hanger

1

**Inst allation recommendation:

JBA recommends in most cases that the vehicle be taken to a reputable exhaust shop.

17039a

4-25-00

We recommend taking the truck to a muffler shop and having all slip connections tack welded

Part s List

A. Head pipe

1

B. Muffler, 24"

1

C. Tail pipe

1

D. Turn out

1

E. 2-1/2" clamp

1

F. 3" clamp

1

G. 3" clamp

1

H. Tail pipe clamp/hanger

1

**Inst allation recommendation:

JBA recommends in most cases that the vehicle be taken to a reputable exhaust shop.

17039a

4-25-00

We recommend taking the truck to a muffler shop and having all slip connections tack welded

Part s List

A. Head pipe

1

B. Muffler, 24"

1

C. Tail pipe

1

D. Turn out

1

E. 2-1/2" clamp

1

F. 3" clamp

1

G. 3" clamp

1

H. Tail pipe clamp/hanger

1

**Inst allation recommendation:

JBA recommends in most cases that the vehicle be taken to a reputable exhaust shop.

17039a

4-25-00

H

D

B

G

F

E

A

C

H

D

B

G

F

E

A

C

H

D

B

G

F

E

A

C

H

D

B

G

F

E

A

C

40-1508