6 cylinder distributors only – PerTronix Ignitor II 9MR-LS1 User Manual

Page 2

POWER & GROUND TESTS

It is imperative that the power and grounds be checked as part of the installation

procedure. After installing the kit within the distributor and with the distributor in

the engine, using a digital multi-meter measure the resistance from the aluminum

plate holding the module to battery (-). The net resistance must be less than 0.2

ohms. Set meter to lowest ohms setting. The net resistance is the meter reading

minus the resistance of the meter leads. If the net resistance is greater than 0.2

ohms the source of the faulty ground must be found and fixed. Usually the source

of the bad ground is easily found by holding one probe on an original location and

moving the second probe toward the static probe. Where the resistance drops

identifies the source.

Maximum resistance from Ignitor plate to battery negative terminal.

0.2 ohms

EXAMPLE:

Resistance from Ignitor plate to battery negative (-) terminal.

0.4 ohms

Resistance of meter leads

0.2 ohms

After subtracting meter lead resistance, your total resistance is:

0.2 ohms

VOLTAGE TEST

1. Do not disconnect wires from Ignition coil and place ignition switch in the “off”

position.

2. Connect jumper wire from negative (-) terminal of the coil to a “good” engine

ground.

3.Connect voltmeter red lead to the positive (+) terminal of the coil and the black lead

to a “good” engine ground.

4.Turn “ON” the ignition switch and note voltage reading on the voltmeter. Quickly

read the voltage and turn ignition “OFF”. Leaving ignition “ON” for an extended

period could result in permanent damage to the Ignitor.

5. SEE CHART BELOW FOR SPECIFICATIONS.

Note: Low voltage can be caused by poor connections, poor contacts in the

ignition switch, ballast resistor, and or a resistance wire in the wiring harness

(Factory Installed).

Minimum

Maximum

Ignition Switch “ON”

8.0V

N/A

Cranking

8.0V

N/A

Engine Running

N/A

16.0V

WIRING INSTRUCTIONS

1. The Ignitor II ignition can be used in conjunction with most ignition coils rated

at 0.45 ohms or greater. For optimum performance purchase and install the

Flamethrower II high performance coil.

2. Attach the black Ignitor II wire to the negative coil terminal. Attach the red Ignitor II

wire to the positive coil terminal. (See Figure 3)

A. Recommended Installation: Many vehicles came equipped with ballast resistor or

resistance wire. To achieve optimum performance from the Ignitor II ignition system, we

recommend removal of these components.

• To remove a ballast resistor, (normally white ceramic blocks 3 to 4 inches long), dis-

connect all wires on both ends of the ballast resistor. Remove the resistor from the

vehicle and splice the disconnected wires together at a single point.

• To remove a resistance wire, trace the coil power wire, which was previously con-

nected to the positive coil terminal, back to the fuse block. Bypass this wire with a

12-gauge copper stranded wire.

B. Alternative Installation: The Ignitor II can also be installed in applications retaining

the ballast resistor or resistance wire.

• Attach the Ignitor II black wire to the negative coil terminal. Attach the Ignitor II red

wire to the ignition side of resistance, or any 12 volt ignition power source.

3. Check to insure that the

polarity is correct, and that

all connections are tight.

4. Re-connect the battery.

5. Perform the Power and

Ground tests. Refer to the

Power and Ground test

procedure.

6. Start the engine and allow

it to reach normal operating

temperature. Check ignition

timing, and adjust to the

desired setting.

+

-

To Ignition

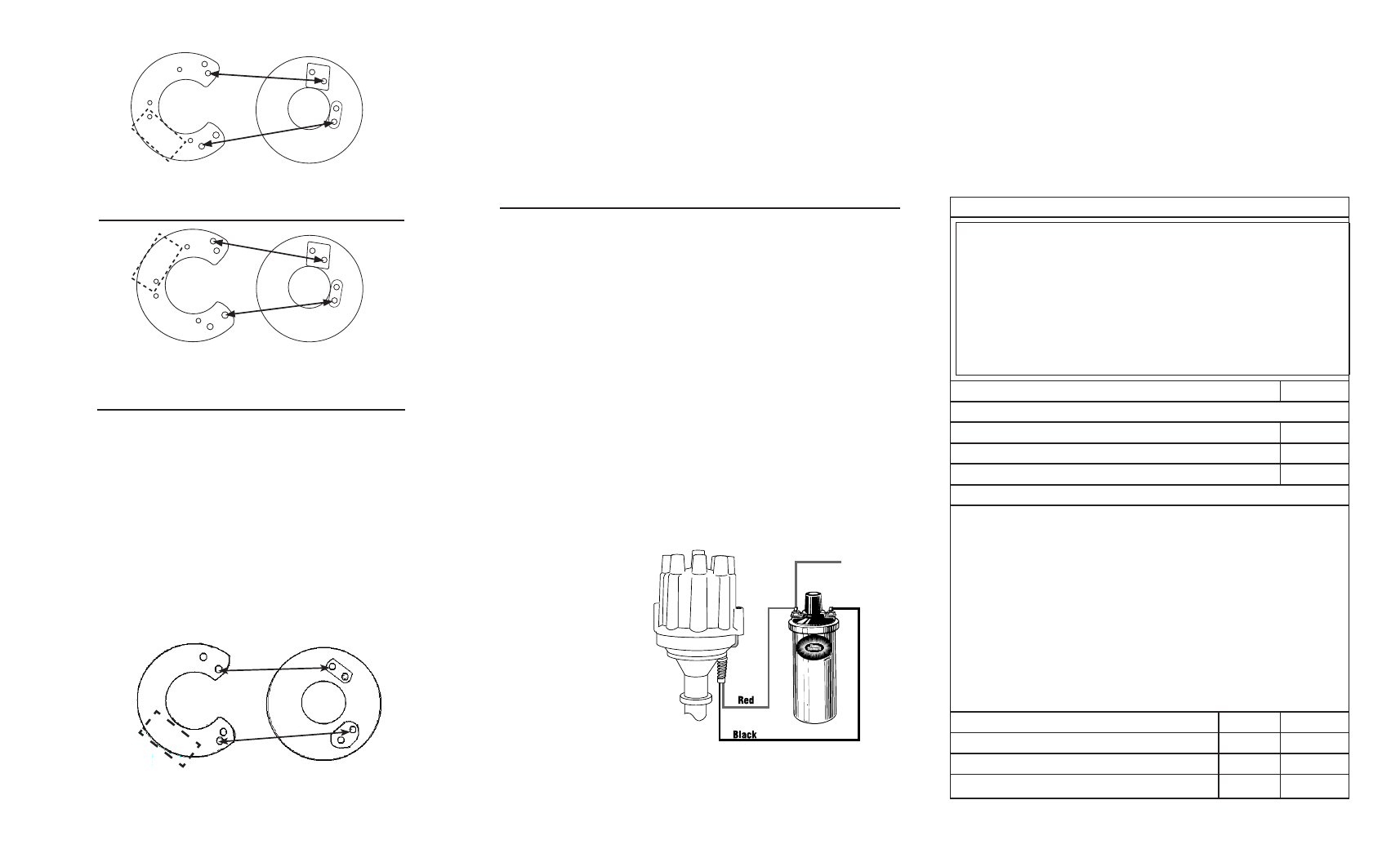

FIGURE 3

(WITHOUT EXTERNAL RESISTOR)

IGNIT

OR

IGNIT

OR

FIGURE 5

(Large Cam 1.00”)

(Measured from point to point)

FIGURE 4

(Small Cam 0.715”)

(Measured from point to point)

FIGURE 6

IGNIT

OR

6 Cylinder Distributors Only

(S112AX & BX DISTRIBUTORS ONLY)

1 Remove distributor cap and rotor from distributor. Do not disconnect the spark plug

wires from the cap. Examine parts for excessive wear. Replace as needed.

2 Remove the point wire from the negative coil terminal.

3 Remove and retain the point and condenser. Installing the Ignitor does not alter

the internal configuration of your distributor. Therefore, the point, condenser and

hardware can be used as backup.

4 Clean all dirt and excess oil from the breaker plate and point cam.

5 6 cylinder distributors only (S112AX & BX):

• The adapter plate needs to be installed with the part number on the adapter plate

facing down.

• Use figure 6 to mount Ignitor to adapter plate.

• Use figure 6 to install adapter plate on to distributor.

6

Secure adapter plate with provided screws

7

Note: A wire tie is included to keep Ignitor wires from rubbing against any moving

parts.

8

Insert both wires through the wire tie and wire access hole in the side of the

distributor housing.

9

Pull the rubber grommet into place. Check to insure that the wires do not contact

any moving parts.

10 Replace distributor cap and rotor. Make sure all spark plug wires are securely at-

tached.

Warning!

DO NOT USE WITH SOLID CORE SPARK PLUG WIRES.