Battery – PerTronix Ignitor 1183P6 User Manual

Page 4

Q. What is the first thing I should check if the engine would not start?

A. Make certain all wires are connected securely to the proper

terminals.

Q. The engine will not start or runs rough. Are there any tests I can

do?

A. Yes, remove the black wire from the ignition switch wire. Connect

jumper wire from the negative (-) side of battery to the Ignitor

black wire. If the engine starts and runs well, you may have high

resistance thru your Ignition switch. This is just a test. Not intended

for permanent installation.

Q. How can I fix a high resistance problem?

A. High resistance can be caused by an external ballast resistor,

resistance wire or in some cases a resisted ignition switch. If the

proper coil is used, remove or bypass all external resistors.

Q. Should I remove the starter bypass wire?

A. No, the starter bypass wire is needed to provide voltage while

starting (cranking).

Q. What type of coil do I need?

A. The ignitor is compatible only with a “points type” coil. Eight

cylinder engines require a minimum of 0.6 Ohms of resistance in the

primary circuit. Four & six cylinder engines require a minimum of 1.5

Ohms of resistance (primary).

Q. How do I check my coil for resistance?

A. First you need an ohmmeter. Remove all the wires from the coil.

Attach the ohmmeter to both the positive and negative terminals.

The reading should be 0.6 Ohms or greater for eight cylinder

engines and 1.5 Ohms or greater for four & six cylinder engines.

(Your local auto parts store can do this for you if you don’t have an

ohmmeter)

Q. What do I do if my coil does not have enough resistance?

A. You may purchase and install a ballast resistor from your local

auto parts store. You may also choose to purchase a Flamethrower

40,000-volt coil, which provides resistance internally. Note: Many

vehicles come with resistor wire or a ballast resistor. These

applications do not need an additional resistor.

Q. What happens if you leave the ignition switch on when the engine

is not running?

A. This can cause your coil to overheat, which may cause permanent

damage to the coil and the ignitor.

Q. May I modify the length of the wires?

A. Yes, you can cut the wires to any length your application may

require. You may also add length of wire if needed (20-gauge wire).

Please make sure all wire splice are clean and connections are

secure.

Q. How can I get additional help?

A. Call our tech line (909-547-9058) for any further instructions or

questions.

Ignitor COMMON QUESTIONS AND ANSWERS

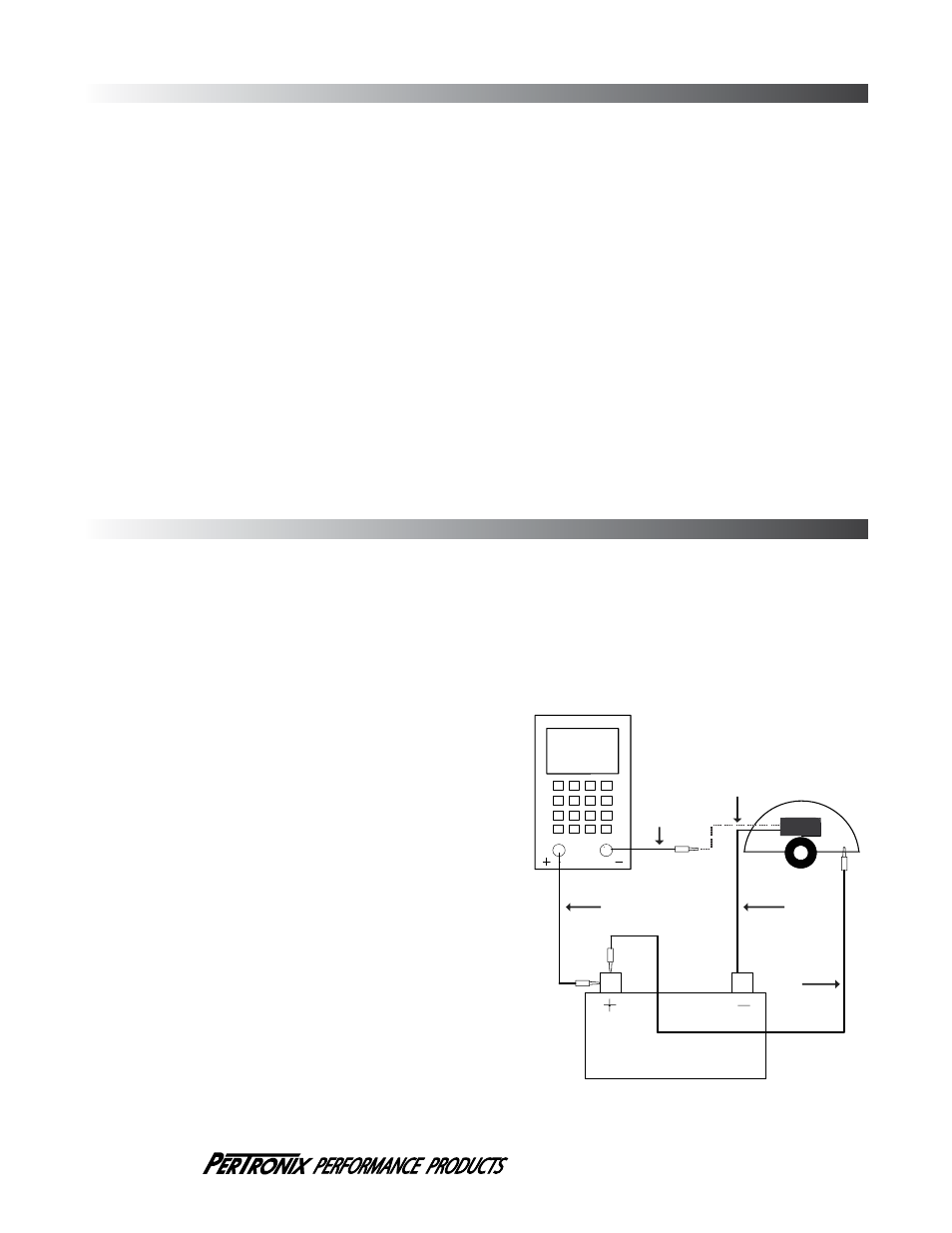

POWER & GROUND TESTS

909-599-5955 www.pertronix.com

VOLTAGE TESTS (ENGINE DOES NOT START):

1. Connect Voltmeter red lead to positive (+) and black lead to negative (-) terminal of the battery.

2. Crank engine and note voltmeter reading. Make sure that the voltage does not drop under 5.2 volts while the engine is cranking.

Check your battery, cables, connections, and starter draw if the voltage drops under 5.2 volts.

3. Attach the voltmeter red lead to the Ignitor mounting plate and the voltmeter black lead to the negative terminal of the battery.

4. Crank engine and note voltmeter reading. The voltage should note drop under 5.2 volts.

ENGINE STARTS AND STALLS (For testing only):

1. Remove Ignitor black wire from the ignition switch wire.

2. Connect Ignitor black wire to (-) negative terminal of battery. Make sure

you make a good connection at the battery.

3. Crank Engine and see if engine starts. If engine starts, check your

Ignition circuit for bad connections, poor contacts in the Ignition switch,

or some form of resistor in the circuit.

IGNITOR

BLACK/WHITE

WIRE

IGNITOR

BLACK WIRE

JUMPER

WIRE

VOLTMETER

BLACK LEAD

VOLTMETER

RED LEAD

BATTERY

IGNITOR

MODULE

VOLTMETER

IGNITOR BENCH TEST:

1. Remove the Ignitor from the distributor, this is a bench test.

2. Connect a jumper wire from the Ignitor plate to the battery positive (+)

terminal.

3. Attach the black/white Ignitor wire to the voltmeter black lead.

4. Attach the Ignitor black wire to the negative terminal of the battery.

5. Attach the red lead from the voltmeter to the battery positive terminal.

6. The voltmeter should read battery voltage once all the connections are

made.

7. The magnet sleeve uses one magnet per cylinder. Using a paper clip,

locate and mark one magnet.

8. Rotate the magnet in front of the module; the meter should drop from

battery voltage to 2-3 volts every time the magnet passes the module.

Note: The voltage may drop to 0 volts, this is normal.

9. If the voltage doesn’t drop and you read constant battery voltage, the

Ignitor has failed.

(FIGURE C)

Page 4 of 5