2 determining the permitted speed of rotation, Important – ROHM KFD-HE - Power chucks with through-hole User Manual

Page 14

7. Calculating the clamping force and speed of rotation

7.1 Determing the clamping force

7.3 Permitted speed of rotation

The following formula applies for determining the

permitted speed of rotation for a specific machi-

ning job:

n

perm

=

[min

--1

]

(Note the number of jaws for Σ M

c.

)

(9)

.

n

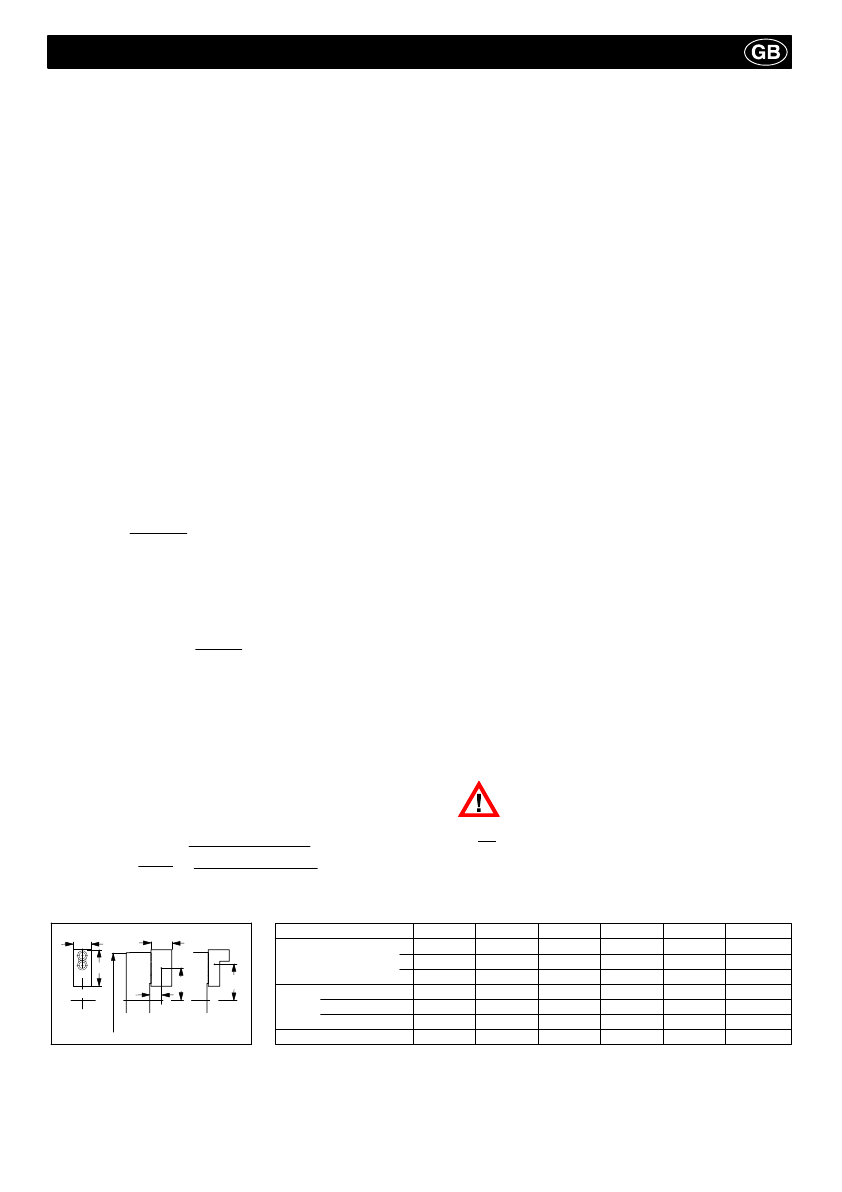

7.2.1 Centrifugal force F

c

, and centrifugal moment M

c

Formulae (1), (2) and (3) produce the following result

for clamping from the outside in:

F

sp

=

-- F

c

[N]

(4)

In this case the centrifugal force F

c

is dependent on

the mass of all jaws m

B

, the centre of gravity radius r

s

and the speed of rotation n.

The following formula can be derived:

F

c

= (m

B

.

r

s

)

.

(

) [N]

(5)

The expression m

B

⋅

r

s

is called the centrifugal

moment M

c

M

c

= m

B

.

r

s

[mkg]

(6)

The following formula applies to chucks with sliding

and false jaws in which the false jaws AB can be mo-

ved in order to alter the clamping area and the sliding

jaws GB approximately maintain their radial position:

M

c

= M

cGB

+ M

cAB

[mkg]

(7)

M

cGB can be obtained from the table below.

M

cAB can be calculated using the following formula:

M

cAB

= m

AB

⋅

r

sAB

[mkg]

(8)

The clamping forces can be obtained by referring to

the clamping force/speed of rotation diagram (see

page 28) when using standard series production

jaws allocated to specific chuck by the chuck

manufacturer.

F

spo

S

sp

π

30

30

π

Do not exceed the maximum speed of rotation

n

max

of the chuck (marked on the body of the

chuck). This applies even if the calculated

permitted speed of rotation n

perm

is greater than

the maximum speed n

max

.

7.2 Determining the permitted speed of rotation

2

The clamping force F

sp

of a rotary chuck is the total of

all jaw forces acting radially on the workpiece. The

clamping force applied before the cutting process and

with the chuck stationary is the initial clamping force

F

spo

. The clamping force F

sp

avialable during the cutting

process is, firstly, the initial clamping force F

spo

existing

with the chuck stationary. This force is then increased or

decreased by the centrifugal force F

c

on the jaws.

F

sp

= F

spo

F

c

[N]

(1)

The (--) sign is for clamping forces applied from the

outside in.

The (+) sign is for clamping forces applied from the

inside out.

The clamping force F

sp

avialable during the cutting

process multiplied by safety factor S

z

²

1,5.

The size of this factor is determined by the accuracy of

the influence parameters such as loading, clamping

coefficient, etc.

F

sp

= F

spz

.

S

z

[N]

(2)

A safety factor of S

p

²

1,5 should be taken into

consideration for the static initial clamping force F

spo

.

Consequently, the following applies for the clamping

force with the chuck stationary.

F

spo

= S

sp

.

(F

sp

F

c

) [N]

(3)

The (--) sign is for clamping forces applied from the

outside in.

The (+) sign is for clamping forces applied from the

inside out.

F

spo

-- (F

spz

.

S

z)

M

c

Important:

A

54

66,7

75

95

95

Max. weight in kg

0,22

0,7

0,88

1,4

1,4

Chuck size

130

170

210

254

315

400

at

max

.

speed

B

A

C

huck

C

o/

LA

RA

rs

B

23

36,5

36,5

45

45

C

29

53

53

54,5

54,5

R

a

max. in mm

39

52

68

80

110

L

a

max. in mm

18

29

29

30

30

Centrifugal moment M

C

GB [mkg]

0,015

0,030

0,051

0,125

0,300