Mounting the chuck on the machine spindle, Maintenance – ROHM KFD-HE - Power chucks with through-hole User Manual

Page 13

3. Mounting the chuck on the machine spindle

1. Mounting the chuck on the machine spindle

1.1 Check the machine spindle or the machine-mounted

finished-machined adapter plate for radial and axial

run-out (permissible tolerance 0,005 mm to DIN 6386

and ISO 3089).

1.2 The adapter plate must be designed so that the

chuck makes full contact with the plate face.

The plate or spindle face must be perfectly flat.

2. Mounting a size 130 and 170 chuck

2.1 Move piston of clamping cylinder with draw tube to

extreme forward position.

2.2 Pull clamping piston (3) in chuck into extreme rear-

ward position (jaws in extreme internal position).

2.3 Screw power chuck on to draw tube as far as it will

go (making sure that the draw tube thread is poperly

aligned).

2.4 Screw chuck back until bore is aligned with positio-

ning element of spindle nose or fastening holes with

fastening screw threads.

2.5 Push chuck against spindle nose or adapter plate

and alternately tighten chuck mounting screws (15).

2.6 Check performance, jaw travel andactuating force.

3. Mounting other chucks (size 210 and above)

3.1 Move piston of clamping cylinder with draw tube to

extreme forward position.

3.2 Remove protective bushing (4) from chuck.

3.3 Screw chuck with rotatable threaded bushing on to

draw tube.

3.4 Push chuck against spindle nose or adapter plate

and alternately tighten mounting screws (15).

3.5 Move piston of clamping cylinder to extreme forward

position, check clearance (1 mm) between piston (3)

and chuck body (1) and correct position of piston by

turning the threaded bushing if necessary.

3.6 Screw on protective bushing and check performance,

jaw travel and actuating force.

3.7 Check mounted chuck for radial and axial runout (at

checking edge).

Removing the chuck is carried out in the

reverse order.

4. Maintenance

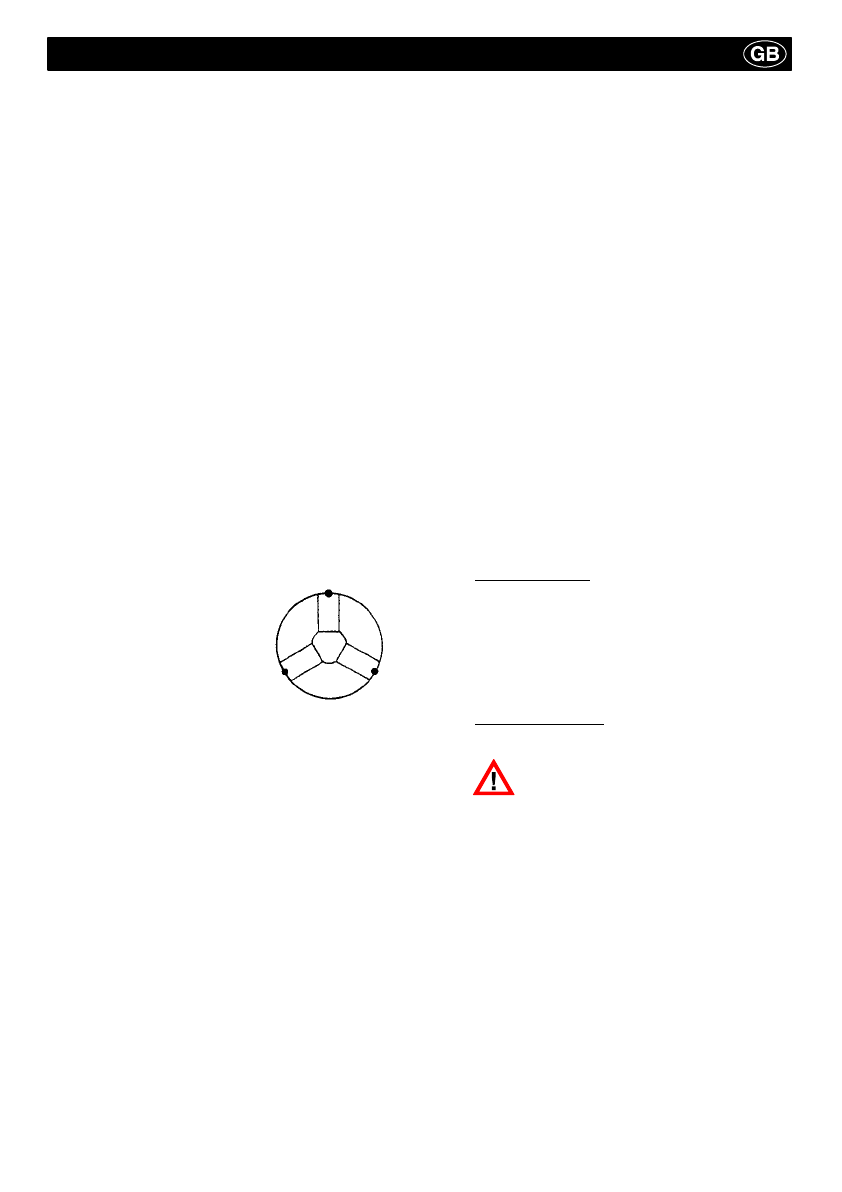

1. To maintain its reliability and

high quality, the chuck must

be lubricated at the grease

nipples at regular intervals

(see illustration).

After lubrication, move the

clamping piston several times

over its full stroke in order to

distribute the grease more

evenly. Then lubricate again.

2. Performance and clamping force must be checked

after some time, depending on the conditions of use.

The most reliable method of measuring the clamping

force is by means of a load cell.

3. Performance check: The clamping piston must

move when the lowest possible actuating pressure of

3-4 bar is applied. However, this method is not relia-

ble enough to serve as a substitute for the clamping

force measurement.

If the clamping force has dropped substantially or

if the clamping piston can no longer be moved with

ease, the chuck must be disassembled, cleaned

and relubricated.

4. Maintenance intervals: Depending on the conditions

of use, but not later than after the specified periods.

We recommend our special grease F 80.

Lubricate all lubricating points

every 20 hours of operation

heavy soling every 8 hours.

Disassemble the chuck and clean all parts

every 2000-3000 hours of operation.

1. Remove protective bushing (4) from chuck.

2.If applicable, unscrew mounting screws (18) and re-

move intermediate flange (7).

3. Pull out clamping piston (3).

4. Unscrew mounting screws (17), remove stop ring (6)

and ring nut.

5. Pull out base jaws (2), each jaw separately, from out-

side to inside.

6. To assemble the chuck, reverse the procedure des-

cribed above, making sure that the individual parts

are correctly numbered.

5. Disassembly and assembly of the chuck

6. Spare parts

When ordering spare parts, please quote the Ident. No. of the chuck and the item number or designation of the desired part

(see page 3). -- The Ident. No. will be found on the face of the chuck.