Ary gauges, Throttle screws, Pulsation dampener pressure snubber – Ashcroft Options User Manual

Page 3: Ashcroft, Accessories

261

Consult factory for guidance in product selection

Phone (203) 378-8281 or visit our web site at

www.ashcroft.com

Ashcroft

®

Accessories

Throttling Devices

A throttling device should be used when a pressure gauge is

subjected to rapid pressure fluctuations, which make the gauge

difficult to read because of rapid pointer movement. Such a

device reduces pressure impact, slows the speed and range of

pointer movement, and prolongs gauge life.

Throttling effect is obtained by installing a restricting orifice

between the gauge socket connection and the Bourdon tube.

Severe service applications are characterized by the presence of

significant levels of pressure pulsation and/or vibration. Gauges

should be protected from severe pressure pulsation by the

inclusion of a dampener such as a throttle plug/screw or porous

metal snubber. If the pulsation is extreme, a liquid-filled gauge,

with dampener, should be used. A liquid-filled gauge will also last

significantly longer than a comparable dry gauge when vibration

is present. If the vibration levels are extreme, the only solution

may be to remotely mount the gauge away from the source of

vibration. In that case capillary tubing may be used to connect

the gauge to the pressure source.

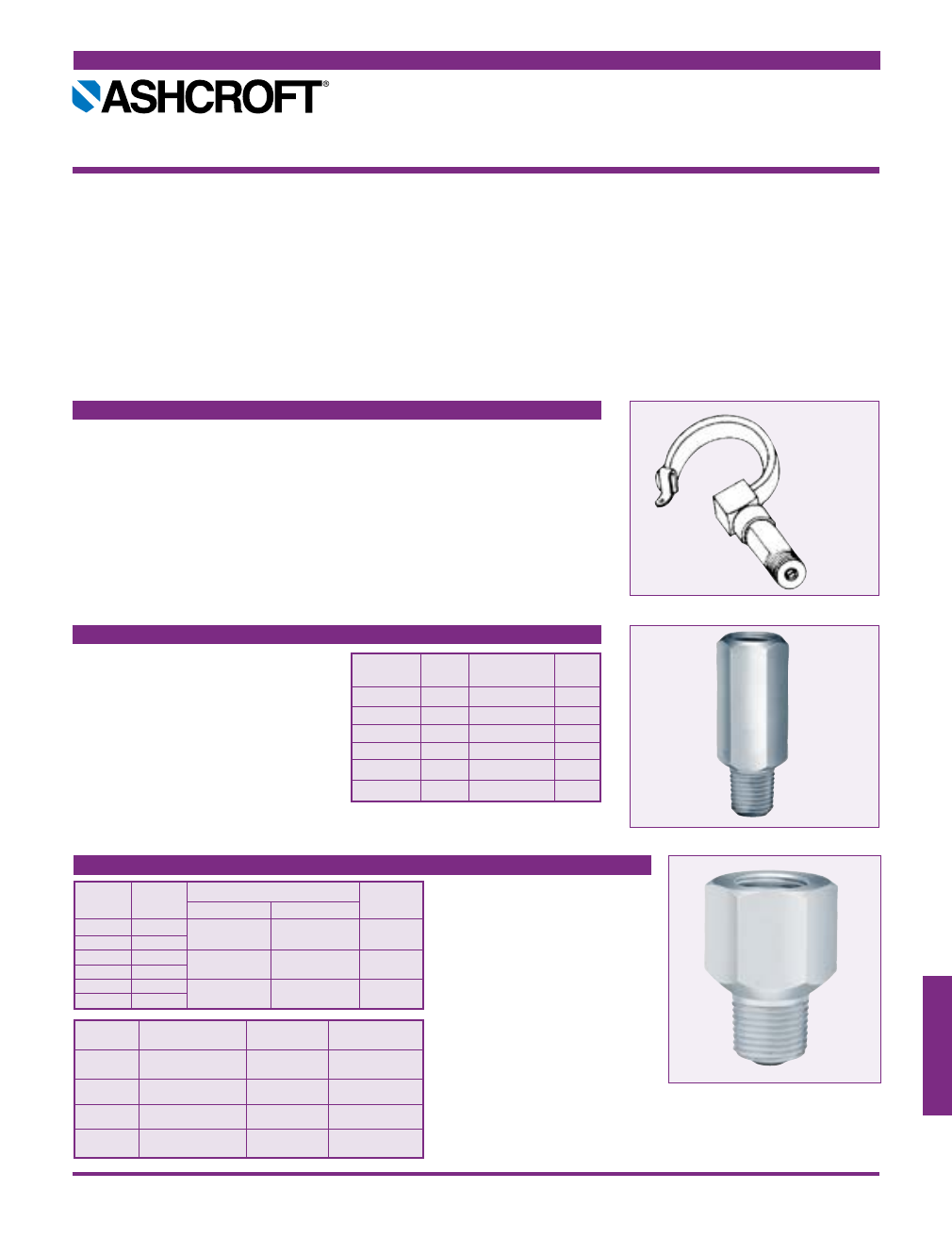

The simplest means of providing a

restriction in the socket, a throttle screw

or throttle plug, should be ordered with

the gauge. Threaded or pressed into

an instrument socket, the throttle screw

orifice selected is based on the viscosity

of the pressure fluid, rapidity of pressure

fluctuations, and the amount of damp-

ening effect desired.

A smaller orifice should be used for

low viscosities, high frequencies, high

pressure and reduced pointer ampli-

tude. To accommodate these variables,

throttle screws are available in these

sizes: 0.0135, 0.020, 0.031, 0.040, and

0.070 inches, in brass and stainless

steel. When orifice size or service condi-

tion is not specified, a 0.020-inch orifice

will be supplied on Duragauge

®

pressure

gauges and a 0.0135, on 25-35 1009

and 63 and 100mm 1008S.

THROTTLE SCREWS

Throttle screw

Type NPT Material Weight

Number Conn.

(oz.)

25-1106B

1

⁄

4

Brass 4

50-1106B

1

⁄

2

Brass 8

25-1106D

1

⁄

4

Steel* 4

50-1106D

1

⁄

2

Steel* 8

25-1106S

1

⁄

4

Stainless steel

4

50-1106S

1

⁄

2

Stainless steel

8

* Internal parts are stainless steel.

Threads onto a gauge socket and pro-

vides restriction by means of a moving

pin, which may be placed in either of

five different sized holes, and thus

allows the user to vary the amount of

dampening to suit requirements. The

pulsating pressure moves the pin up

and down, providing a self-cleaning

action. Dampeners are shipped with

a pin in the “middle” hole, and may be

used in either a vertical or horizontal po-

sition. Maximum pressure is 5000 psi.

PULSATION DAMPENER

Porosity

Max Pore Cap.

CFH at 1 psi

For use with

Opening (Inches)

Diff. Press.

D

0.005

6.5

E

0.0025

3.0

G

0.0008

1.1

HX

0.0006

0.4

Used for dampening and filter-

ing, the snubber has a metal

disc available in four standard

grades of porosity. The one

best suited for the application

can be selected from the chart,

using the same guidelines as for

throttle screws. Due to the large

filter area, the snubber has less

tendency to clog than orifice-

type devices. All-metal construc-

tion permits the snubber to be

washed in a variety of common

solvents.

Oil

(50 to 500 S.S.U.)

Air, Steam

and Gases

Mercury

Manomometers

Water & Light Oils

(Under 50 S.S.U.)

Type NPT

Material

Max psi

Number

Conn.

Housing

Filter Disc

Rating

25-1112B

1

⁄

4

Brass 316 10,000

50-1112B

1

⁄

2

stainless steel

25-1112S

1

⁄

4

303 316 15,000

50-1112S

1

⁄

2

stainless steel

stainless steel

25-1112M

1

⁄

4

R Monel

Monel

15,000

50-1112M

1

⁄

2

PRESSURE SNUBBER