Ashcroft 80-81 - Isolation Rings User Manual

Page 8

8

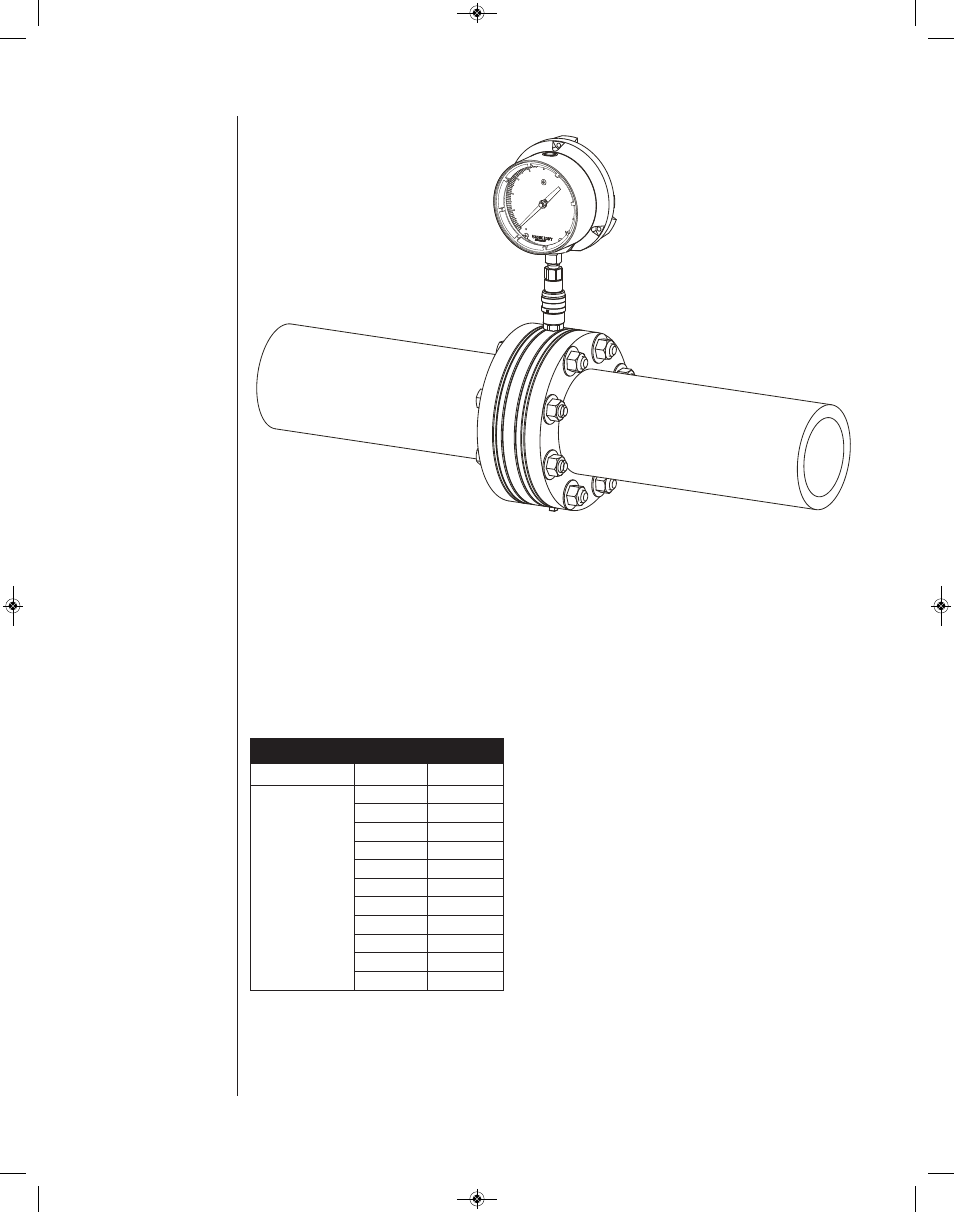

Type 81 Bolt-Thru

(Installed View)

Prior to installation, please follow the recommended manufacturer procedure:

A. Confirm process has been shut down with process pressure relieved and piping drained.

B. Provide pipe flange gasketing, mounting bolts, lockwashers and nuts (not supplied by Ashcroft).

Step 1: Isolation ring and flange gaskets should be centered between process piping flanges.

For Type 80 Wafer: Assembly is installed by placing centering gages (shims) on the two bottom-most flange

bolts; these are supplied by Ashcroft with each isolation ring assembly. Refer to the following table for cen-

tering gage size based on flange class rating. Note: Centering gauges may be removed afterwards by

breaking.

Step 2: Position Type 80 Wafer isolation ring with centering-gages or Type 81 Bolt-Thru using two bottom-

most bolts through unit and process flanges. Take care to ensure that any attached instruments are directed

in a vertical (upward) configuration, while measuring devices (e.g. gauge, switch, transducer) are also posi-

tioned between the two upper-most flange bolts to prevent obstruction with the process piping.

ANSI/ASME

NPS

CENTERING

CLASS RATING

GAGE SIZE

Class 150

All Sizes

1/8˝

2˝

1/4˝

3˝

3/8˝

4˝

1/4˝

6˝

11/16˝

8˝

11/16˝

Class 300

10˝

9/16˝

12˝

3/8˝

14˝

13/16˝

16˝

5/8˝

18˝

1-1/16˝

20˝

1-1/16˝

I&M008-10223_USER_layout 6/17/14 3:27 PM Page 8