Agilent Technologies E3614A User Manual

Page 23

A-9

After the trouble has been isolated to one of the feedback

loops, troubleshooting can proceed as described in Tables A-

4, A-5, or A-6.

Series Regulating Feedback Loop. When troubleshooting

the series regulating loop, it is useful to open the loop since

measurements made anywhere within a closed loop may

appear abnormal. With a loop closed, it is very difficult to sep-

arate cause from effect. As described in Tables A-4 and A-5,

the conduction or cutoff capability of each stage is checked

by shorting or opening a previous stage, as follows:

1.

Shorting the emitter to collector of a transistor simu-

lates saturation, or the full ON condition.

2.

Shorting the emitter to base of a transistor cuts it off,

and simulates an open circuit between emitter and

collector.

Although a logical first choice might be to break the loop

somewhere near its mid-point, and then perform successive

subdividing tests, it is more useful to trace the loop from the

series regulator backwards a stage at a time, since loop fail-

ures occur more often at the higher power levels.

Preregulator Feedback Loop. The preregulator feedback

loop (SCR control circuit) can be conveniently checked using

Table A-6. As indicated in Table A-6, the control circuit is

checked by starting with the waveform at point 7 and point 6

(shown on the schematic diagram) and tracing forwards and

backwards from this point.

Overvoltage Protection Circuit Troubles

When troubleshooting the overvoltage protection circuit, it is

useful to check the turn-on overshoot control circuit which

includes U20 and Q10. The function of the control circuit is to

slow down the rising speed of the +15 V bias the moment the

power is turned on. This function prevents the supply from

false OVP tripping the moment the power is turned on. After

the troubles has been isolated to overvoltage protection cir-

cuit, troubleshooting can proceed as described in Table A-7.

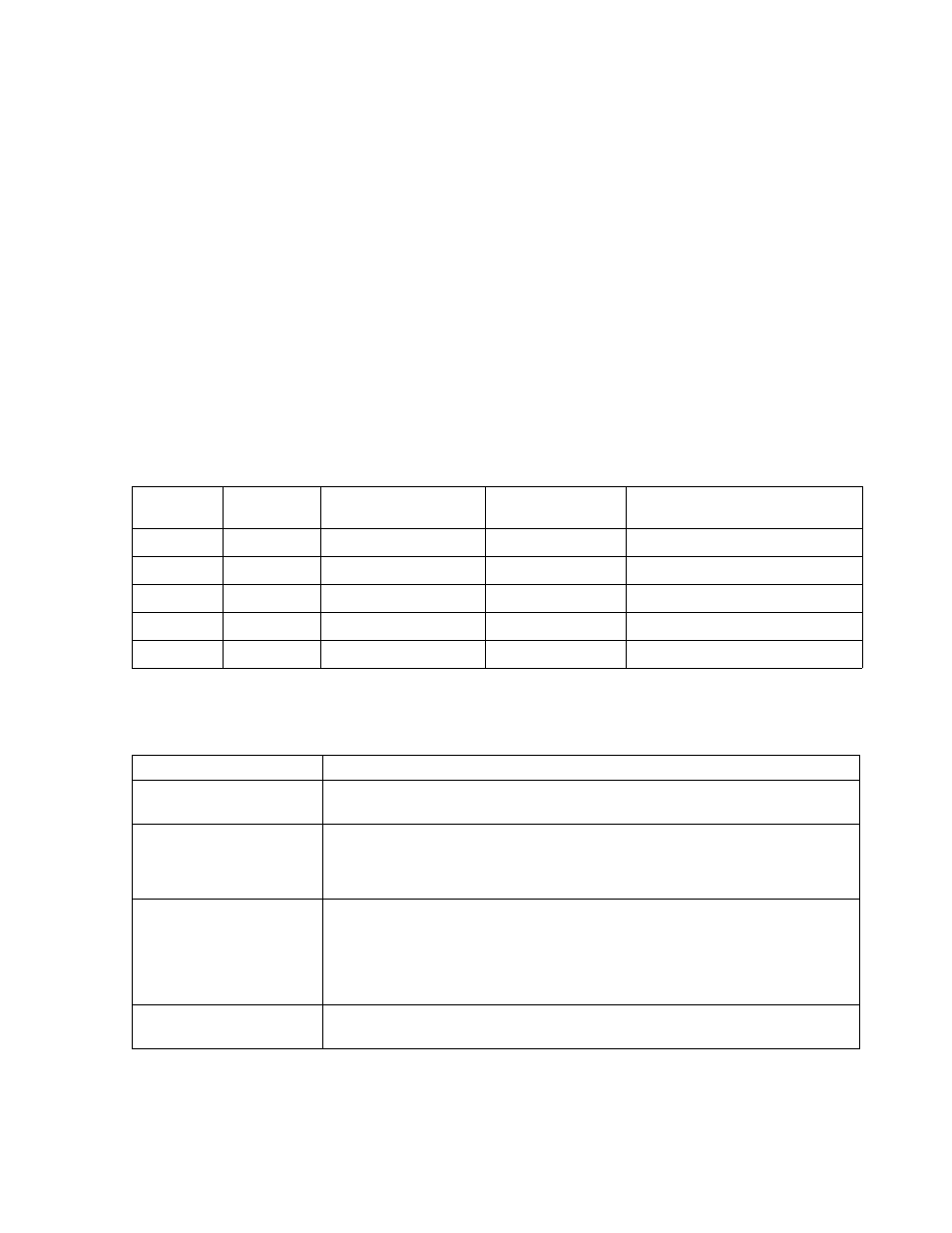

Table A-2. Reference and Bias Circuit Troubleshooting

METER

COMMON

METER

POSITIVE

NORMAL INDICATION

NORMAL RIPPLE

(p-p)

PROBABLE CAUSE

TP6

point 2

+15.0 +/- 0.3 Vdc

2 mV

Check U13, CR31, and CR32.

TP6

point 4

-12.0 +/- 0.3 Vdc

2 mV

Check +15 V bias or U14.

TP6

TP7

+10.5 +/- 0.2 Vdc

2 mV

Check +15 V bias, U11, and U14.

TP6

point 3

-5.1 +/- 0.5 Vdc

2 mV

Check -12 V bias or VR1.

TP6

point 5

+5.0 +/- 0.3 Vdc

4 mV

Check U1 and CR2.

Table A-3. Overall Troubleshooting

SYMPTOM

CHECKS AND PROBABLE CAUSES

High Output Voltage

a. Check series regulator feedback loop or preregulator feedback loop.

b. Refer to "Regulating Loop Troubles" paragraph or Table A-4 or A-6 as instructed.

Low and No Output Voltage

a. If output is zero, check fuse.

b. Check series regulator feedback loop or preregulator loop.

Refer to "Regulating Loop Troubles" paragraph or Table A-5 or A-6 as instructed.

c. Check CR20 shorted.

High Ripple

a. Check operating setup for ground loops.

b. If output floating, connect 1

µ

F capacitor between output and ground.

c.

Ensure that the supply is not crossing over to constant current mode

under loaded conditions.

d. Check for low voltage across C7 or Q1 and Q4.

e. Check for excessive ripple on reference voltages (Table A-2).

Poor Line Regulation

(Constant Voltage)

a. Check +10 V reference voltage.

b. Check U9.