Dake Model SE 712 User Manual

Page 9

- 8

TOOTH

SELECTION

You need to consider:

1.The width of the cut. That is, the distance in the cut that each tooth must travel from the

point it

Enter the work piece until it leaves the work piece, and

2.The shape of the work piece.

Squares, Rectangles, Flats (Symbol :

)

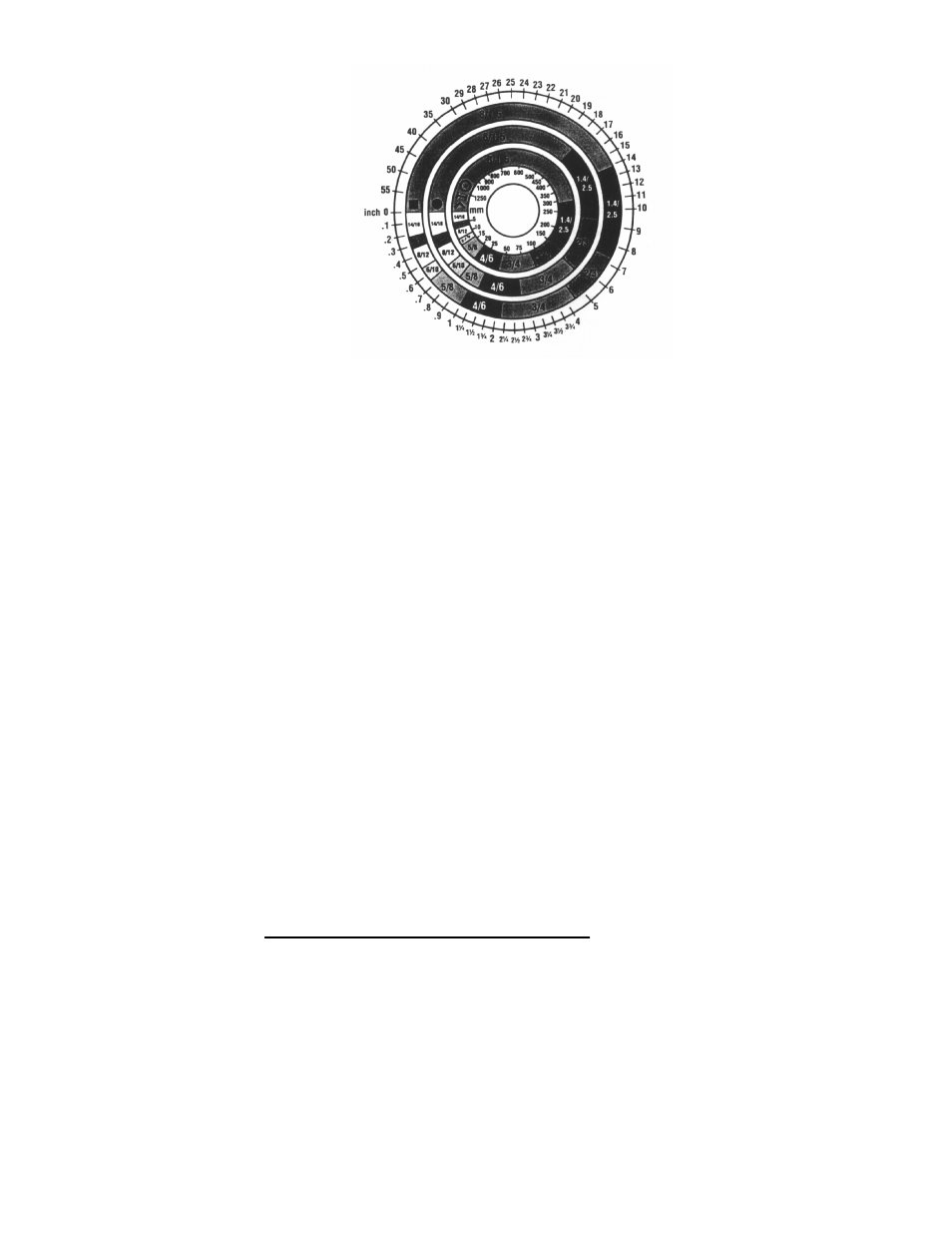

Locate the width of cut on the chart. (Inches on the outer circle and millimeters

on the inner circle.) Select the tooth pitch on the ring marked with the square

shape which aligns with the width of cut.

EXAMPLE: 6" (150mm) square, use a 2/3 Vari-Tooth.

Round Sollds (Symbol : )

Locate the diameter of your work piece on the chart. Select the tooth pitch on the

ring marked with the round shape which aligns with the size of stock you are

cutting.

EXAMPLE: 4" (100mm) round, use a 3/4 Vary-Tooth.

Tubing, Pipe, Structural’s( Symbol : O H ^ )

Determine the average width of cut by dividing the area of the work piece by the

distance the saw blade must travel to finish the cut. Locate the average width of

cut on the chart. Select the tooth Ditch on the ring marked with the tubing and

structural shape which aligns with the average width you are cutting.

EXAMPLE: 4"(100mm) outside diameter, 3"(75mm) inside diameter tubing.

4"(100mm) OD

=12.5 sq.ln. (79cm

2

)

3"(75 mm ) ID = 7.0 sq.ln. (44cm

2

)

Area = 5.5 sq.ln. (35cm

2

)

5.5 sq.ln. (35cm

2

) / 4" (100mm) distance =1.38(35mm) average width

1.38" (35mm), use a 4/6 Vary-Tooth

NOTE:

The band speed and cutting rate recommendations presented on this

chart are approximations and are to be used as a starting point for most

applications. For exact sawing parameters' consult your saw blade supplier.