Dake Utility - Bench User Manual

Page 9

8

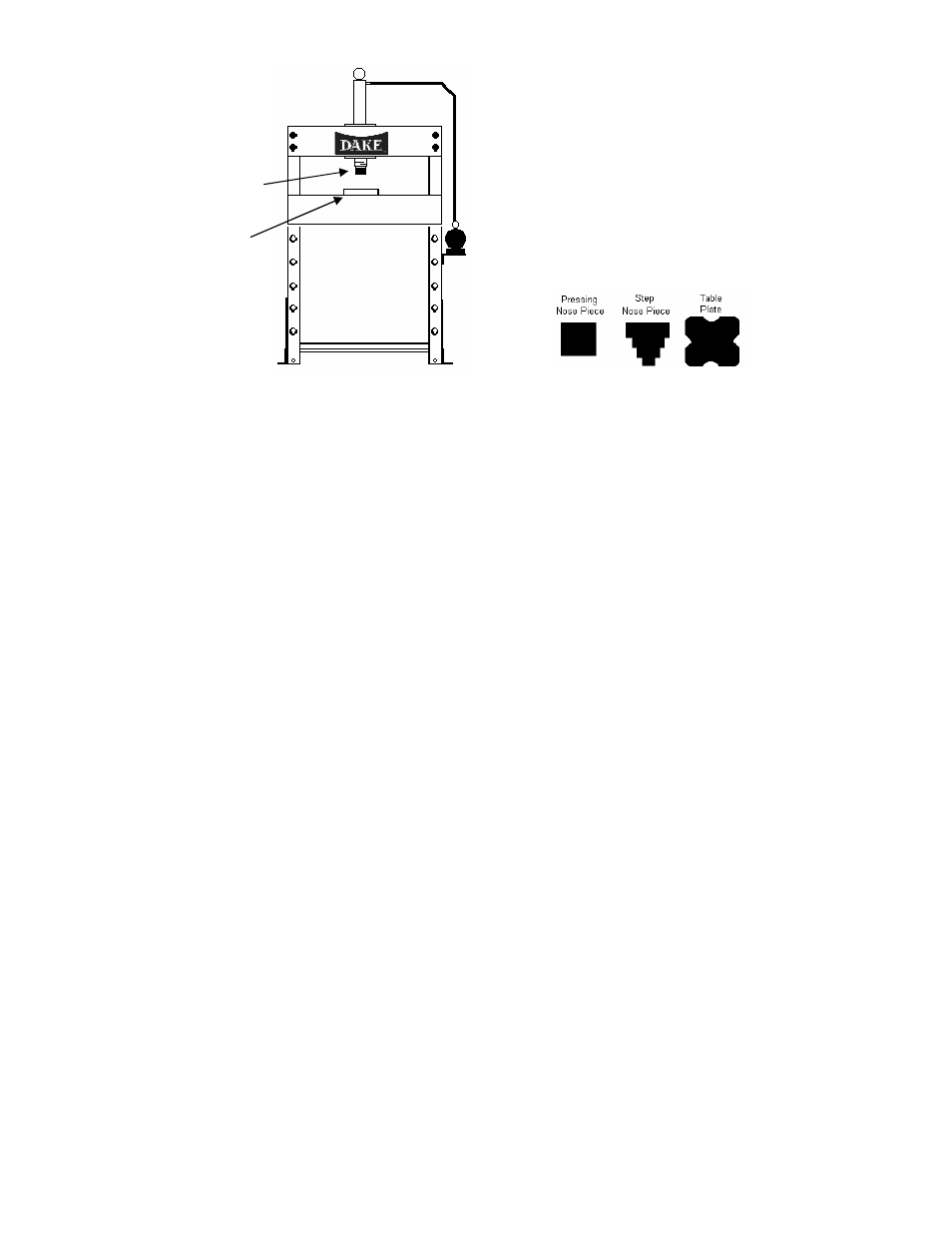

Nose piece

Table block

NOTE:

System is filled with oil and may take a few pumps to fill all lines.

Close the pump valve and pump to check for piston action, and for

leaks.

If air appears to be in the system, open the valve handle and pump

vigorously about a dozen times. Close valve and try again.

STEP 9:

Chose location placement as described on page 2. Mount the press securely.

You are now ready to use the press.

5. OPERATION (PROCEDURE)

Always use the supplied nose pieces. The flat nose piece will be good for most pressing and

flattening operations. The step style nose piece will work well for pressing bearing, bushing

and parts that have a hole that the nose piece will fit into. This nose piece will help support or

hold the piece during pressing operations.

There are two table plates that should always be used as a backing plate during pressing

operations. You will find notches in these table plates to allow you to use the press as a

straightening press for axles, shafts, etc and most round stock.

When using your press always use the highest table setting to minimize the stroke distance

of the ram.

Note

: Only use supplied table pins. Do not weld or pin table. Once a part is put in

the press and is clamped or braced securely, close the pumping unit release valve handle.

(Clockwise). Pump the handle to lower the ram. Pump until pressing operation is completed.

If you need to maintain pressure leave the valve on the pumping unit closed. When

operation is complete, turn the valve counter-clockwise to release pressure and raise the

ram. Once the ram has been raise just above the work close valve again and repeat

operation on the next part. There is no need to raise the ram all the way to the top each time.

If pressing application requires a certain tonnage, press until the gauge reads the