Hawkeye Tank Preparation User Manual

Page 2

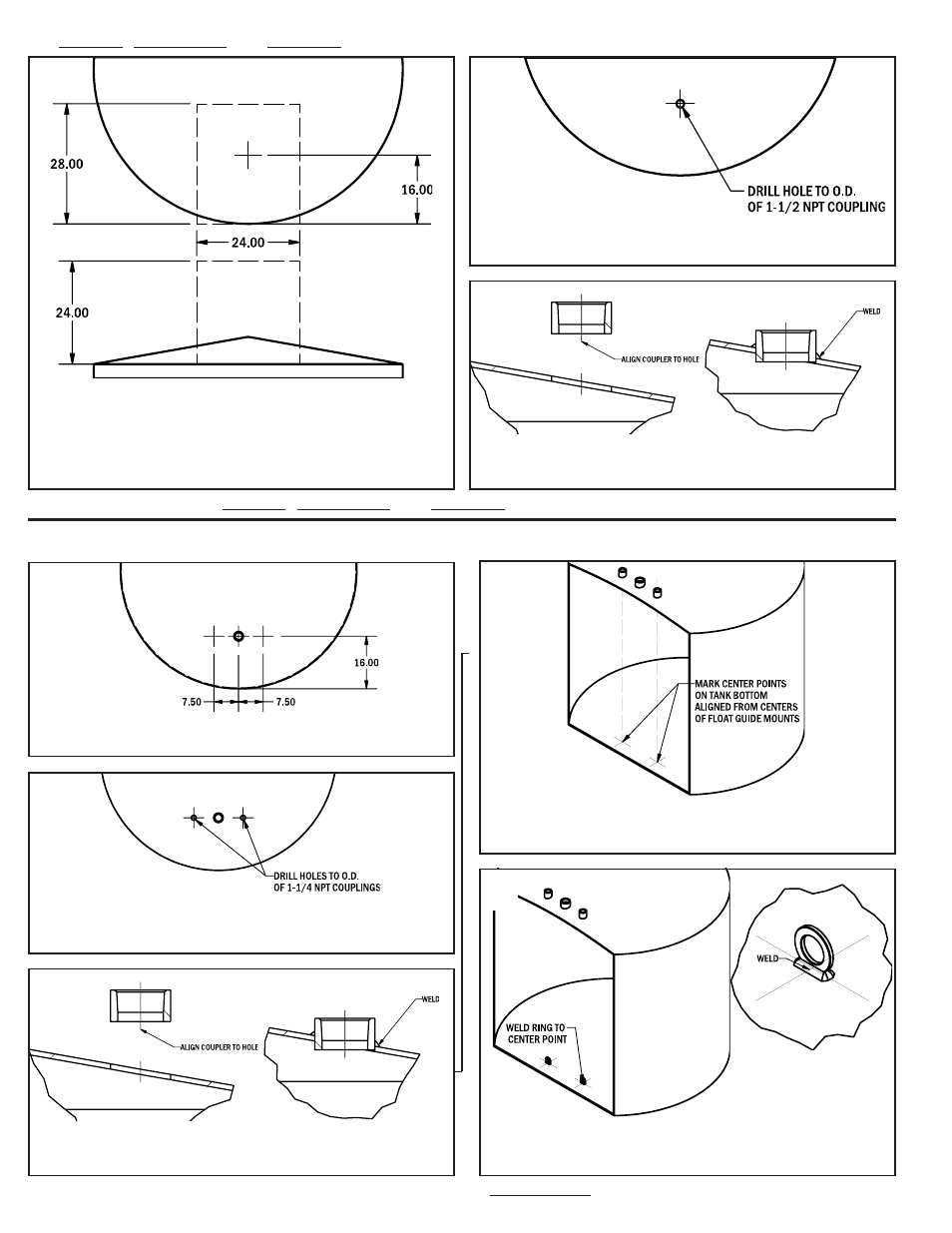

Mark a location on the top of the tank for the gauge head connection. The

connection shall be 16 in. from the tank wall, with clearance of 3 ft above,

and 1 ft to each side of the gauge head. Ensure a clear path, free of ob-

structions, on the outside of the tank leading from the gauge head mount

to the ground.

Cut a hole to match the diameter of the coupling at the marked location.

Align the1-1/2 NPT coupling to the cut hole and weld to the tank roof

using appropriate weld procedures.

1.)

2.)

3.)

►

►

►►

►

Mark two locations, 7.5 in on either side of the gauge head mount.

Cut a hole to match the diameter of the 1-1/4 couplings at the marked lo-

cations.

Align a 1-1/4 NPT coupling to each cut hole and weld to the tank roof

using appropriate weld procedures.

Suspend plumb bob from centre of float guide mount (1-1/4 NPT cou-

pling) to tank floor.

At the plumb location on the tank floor, weld the float guide anchor ring.

See section D for No-Weld alternative to float guide anchors

1.)

2.)

3.)

4.)

5.)

A2.) Roadside , Sparrowhawk , and Model 750 Gauge Head

Roadside , Sparrowhawk , and Model 750 Gauge Head Preparation Complete, proceed to section B.

Float Guide Kit Preparation Complete, proceed to section C.

B.) Preparing the Tank for a Float Guide Kit

►

Hawkeye Industries Inc.

2