Hawkeye Goshawk User Manual

Hawkeye Sensors

GOSHAWK INSTALLATION, OPERATION AND TROUBLESHOOTING MANUAL.

1

REPLACES “GOSHAWK INSTALLATION INSTRUCTIONS, MAY 2010”

VALID FOR ALL GOSHAWK MODELS MANUFACTURED SINCE MID-2008.

1.0 INTRODUCTION

1.1 DESCRIPTION

The Goshawk Level Transmitter is a bolt-on, two-wire 24 VDC loop powered

transmitter that adds 4 – 20 mA electronic output to Hawkeye Industries Inc.’s Redtail

Hawk and Roadside Hawk gauge heads. The transmitter connects mechanically to the

gauge head cable reel, converting the rotational position of the cable reel to a precise

current output.

Because Hawkeye’s Dry-Seal gauge heads use wound reels of cable as opposed to

pulleys, the rotational position of the reel provides accurate and repeatable float and

indicator position information. The solid-state nature of the transmitter electronics

allow the device to continue to track (but not transmit) float position information even

when unpowered. Powering the unit back up will provide instantaneous level position.

1.2 SAFETY CONSIDERATIONS

The Goshawk Transmitter carries CSA Hazardous Location Certification for Class I Div

1 Group C & D. Some parts of the transmitter may be classified as sparking

components, and as such the cover should only be removed from the device when in

a non-energized state, or in an non-hazardous location. Several procedures in this

manual require power to be disconnected from the transmitter before proceeding.

Failure to do so will provide erroneous calibration information, and may cause damage

to the transmitter, calibration equipment and / or process control equipment.

NOTE: INFORMATION REQUIRED FOR SUCCESSFUL INSTALLATION

CAUTION OR IMPORTANT: INFORMATION IF NOT HEEDED MAY RESULT IN

DAMAGE TO THE EQUIPMENT AND/OR INSTALLATION FAILURE

WARNING: INFORMATION THAT IF NOT FOLLOWED MAY RESULT IN INJURY OR

SHOCK.

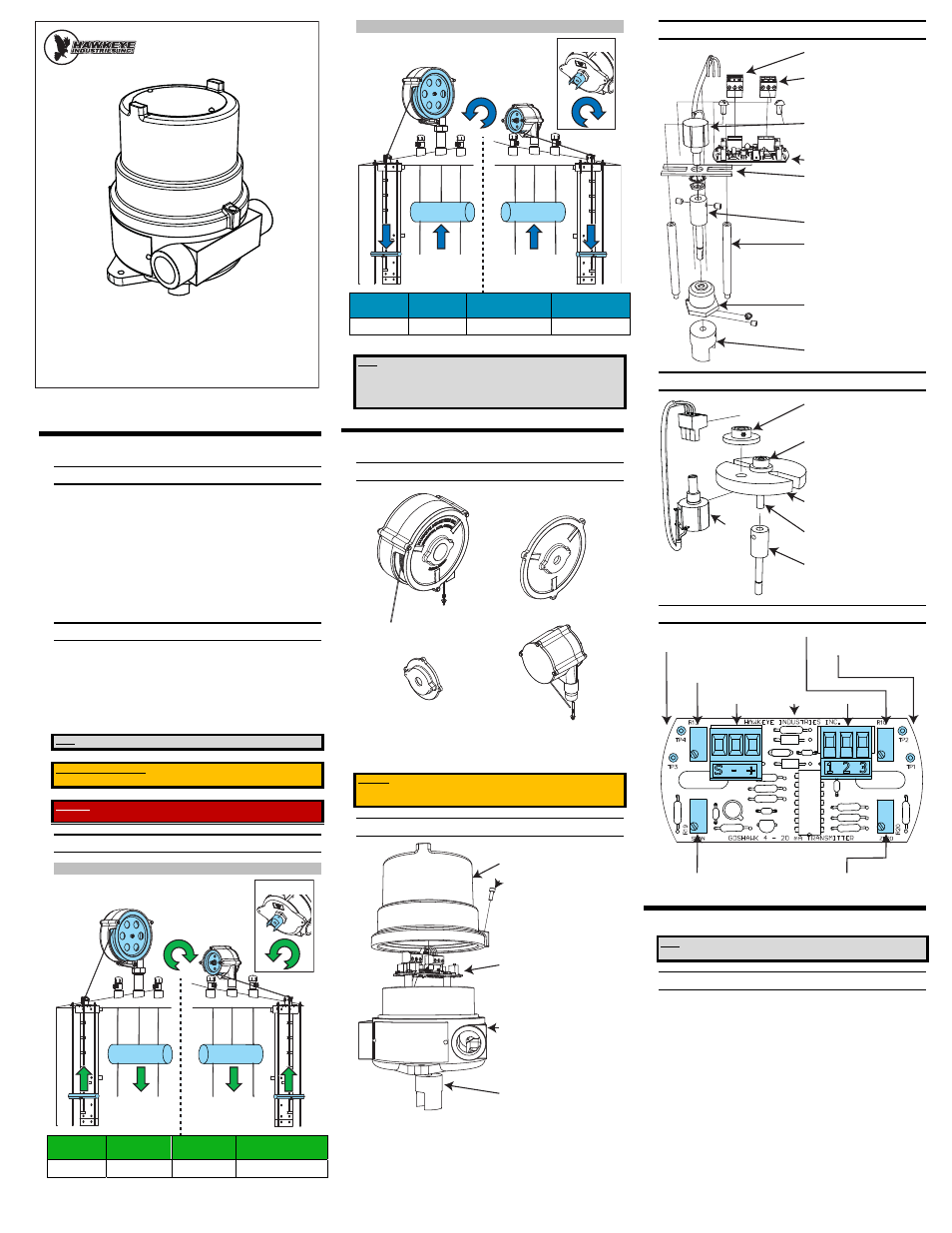

1.3 ROTATIONAL ORIENTATIONS

1.3.1 EMPTYING DIRECTION

Indicator

moves

Float

moves

Atmospheric

Reel rotates

Transmitter rotates

UPWARD DOWNWARD CLOCKWISE COUNTERCLOCKWISE

FIGURE 1

EMPTYING DIRECTION

1.3.2 FILLING DIRECTION

Indicator

moves

Float

moves

Atmospheric reel

rotates

Transmitter

rotates

DOWNWARD UPWARD COUNTERCLOCKWISE CLOCKWISE

FIGURE 2

FILLING DIRECTION

NOTE: ROTATION DIRECTIONS FOR THE GAUGE HEAD AND TRANSMITTER ARE

OPPOSITE TO ONE ANOTHER FOR THE SAME FILLING / EMPTYING DIRECTION IN

THE ORIENTATIONS ILLUSTRATED ABOVE. THIS IS DUE TO THE NATURAL

ORIENTATION OF EACH DEVICE THE READER WILL ENCOUNTER OVER THE

COURSE OF INSTALLING AND TROUBLESHOOTING THE TRANSMITTER.

2.0 PART IDENTIFICATION

2.1 GAUGE HEADS

FIGURE 3

GAUGE HEADS AND THEIR ELECTRONIC COVERS

CAUTION: THE ELECTRONIC COVER PLATE CAN ONLY BE INSTALLED ON THE

ATMOSPHERIC SIDE OF THE GAUGE HEAD. INSTALLATION ON THE PRESSURE

SIDE WILL COMPROMISE THE GAUGE HEAD SEALS.

2.2 TRANSMITTER - EXTERNAL

2.3 TRANSMITTER - INTERNALS

2.4 TRANSMISSION (GH II AND GH III)

2.5 PCB

3.0 BASIC INSTALLATION

NOTE: BEFORE STARTING INSTALLATION, READ AND UNDERSTAND ALL THE

INSTRUCTIONS PROVIDED BELOW.

3.1 TOOLS REQUIRED

Transmitter Installation

Redtail

Wrenches ............................................................ 7 / 16 in and 9 / 16 in

Pliers ....................................................Vise-grip style locking pliers

Roadside

Wrenches .............................................................. 7 / 16 in and 1 / 2 in

Pliers ....................................................Vise-grip style locking pliers

Electrical Connections & Calibration

Allen Key

................................................................................. 7 / 64 in

Screw Driver

........................................................... 1 / 8 in wide Slot Driver

Loop Calibrator ...................................................................... Fluke 789 or Eq.

Or:

Multimeter ...................................................... Fluke 187 or Eq.

and

Power

Supply

....................................................... 13 – 24 VDC

and

Load Resistance ........................................................... see 7.3

GOSHAWK

LEVEL

TRANSMITTER

OPERATION AND

TROUBLESHOOTING GUIDE

Refer to www.hawk-eye.com for

latest manuals and information

READ AND UNDERSTAND THIS DOCUMENT BEFORE

INSTALLING AND USING THE GOSHAWK TRANSMITTER

REDTAIL SYSTEM

ROADSIDE SYSTEM

GOSHAWK

REDTAIL SYSTEM

ROADSIDE SYSTEM

GOSHAWK

REDTAIL

GAUGE HEAD

REDTAIL

ELECTRONIC COVER PLATE

ROADSIDE

ELECTRONIC COVER PLATE

ROADSIDE

GAUGE HEAD

[A] COVER

[B] COVER STAKE

SCREW

INTERNALS

SEE [E] THRU [L]

[C] BOX

[D] TRANSITION

COUPLING

[E] POWER TERMINAL

(ORANGE)

[F] ENCODING

POTENTIOMETER

TERMINAL

(GREY)

[H] PCB

[K] STANDOFFS

[D] TRANSITION

COUPLING

[G] ENCODING

POTENTIOMETER

[I] H-CLIP

REPLACED

BY [M] - [P]

IN GH II AND GH III

[J] OPERATOR SHAFT

[L] OPERATOR BUSHING

[M] IDLE GEAR

(LARGER)

[G]

[N] DRIVE GEAR

(SMALLER)

[O] TRANSMISSION

CHASSIS

[P] TRANSMISSION

CENTRE

AXLE

[J]

[E]

[F]

[U] R19 (SPAN)

TRIMMER

[V] R20 (ZERO)

TRIMMER

[H]

[Q] TEST POSTS

TP3 & TP4

[S] R10 TRIMMER

[R] R13 TRIMMER

[T] TEST POSTS

TP1 & TP2