AMETEK 1025 Foot & Palm Switches User Manual

Page 16

Chapter 3: Operating Instructions

Operating Manual

12

9.

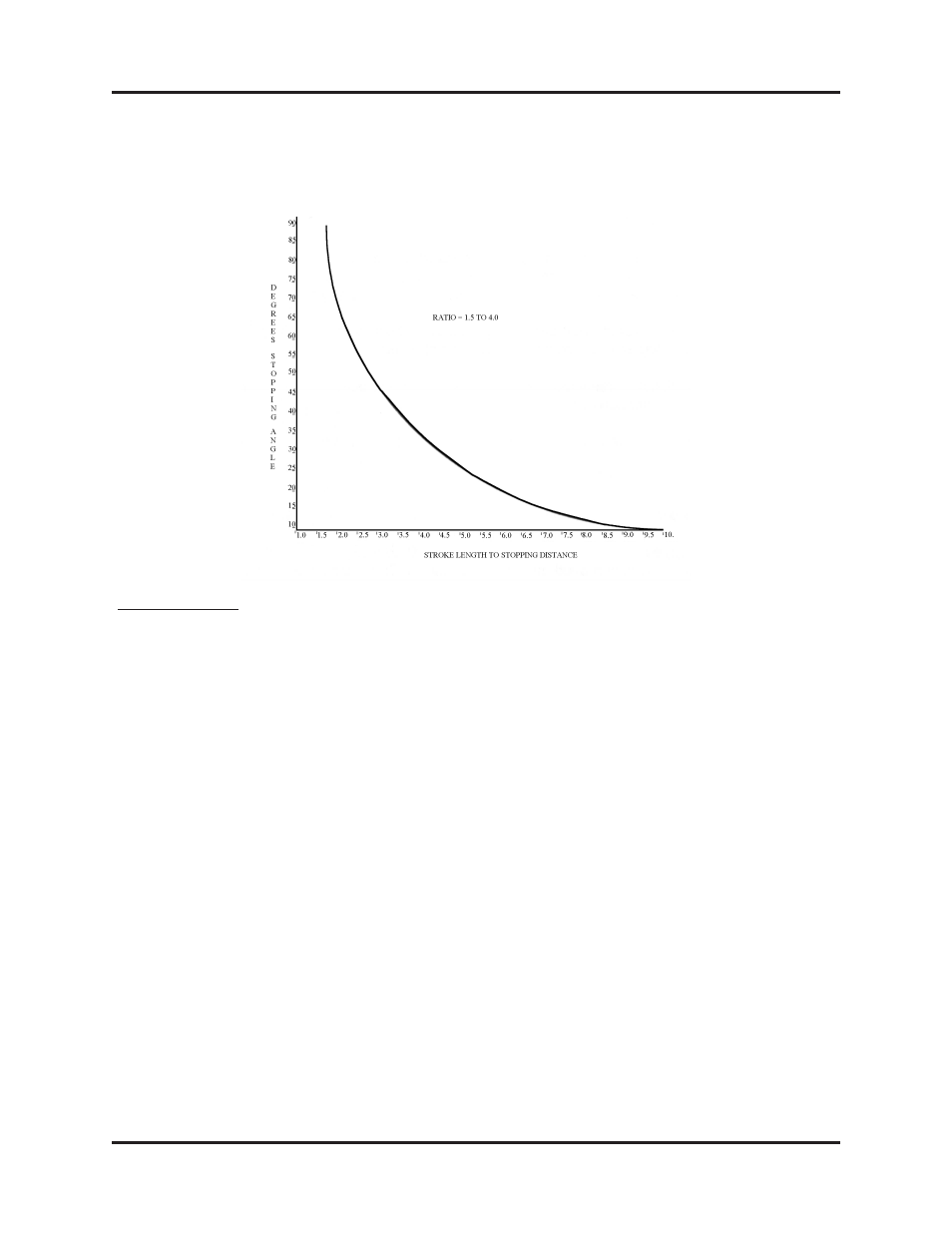

Determine the ratio of press stroke to stopping distance (divide stroke by

stopping distance). Locate this ratio on the horizontal axis of the graph, move

up to the curve and read across to the vertical axis, fi nding the stopping angle

in degrees.

Review Points:

1.

Be sure to start at exactly 90 degrees or 270 degrees by observing crankshaft

or indicator.

2.

Be sure press does not go through bottom or top of stroke.

3.

Small differences in stopping distance make for large differences in stopping

angle, especially when the stopping angle exceeds 45 degrees. Read the CSP

dial carefully.

When determining stop angle be sure of the following:

1.

The P/V transducer cable must be parallel to the slide motion. The cable

magnet must be directly above the P/V transducer.

2.

In down stroke tests, the ram must stop before it reaches the bottom of the

stroke.

3.

The mid-stroke position can be used as the 90 degree crankshaft position.

Since this is one of the reference points used to make linear measurements of

the ram travel to determine stop angle, care must be taken to initiate the stop

at exactly the 90 degree position.

4.

If the press is equipped with a functioning angular position indicator, this can

be used to indicate crank or cam angular position. If no indicator is available,

the angular position may be determined from the crank or camshaft position.

Mark the 90 degree position.