Part numbering, 12 s x – AMETEK 925 Linear Cable Reel Sensor User Manual

Page 3

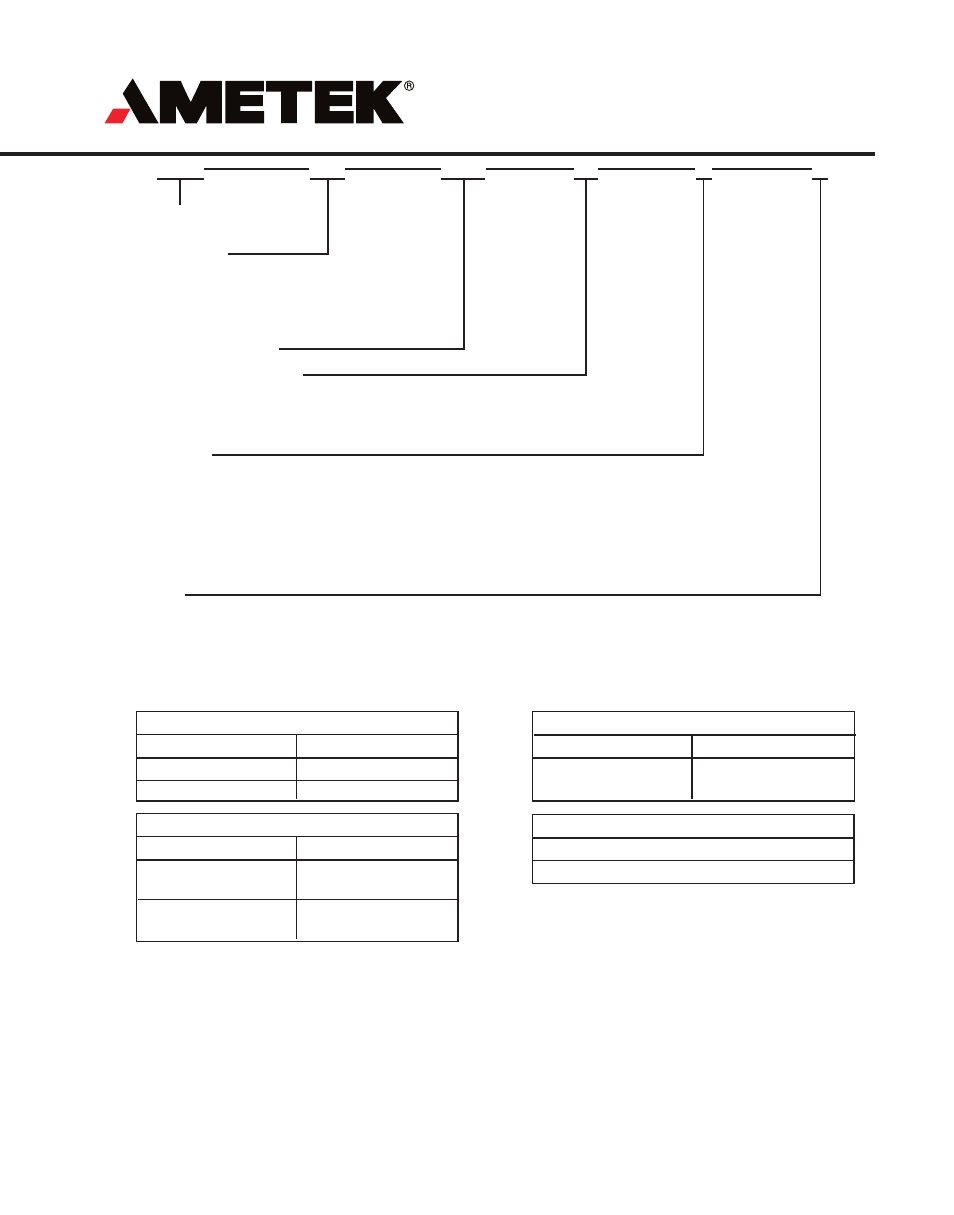

925

A1

100

Cable Reel

Sensor

Hardware Type

A1 = 0 - 96 inch Stroke

A2 = 97 - 192 inch Stroke

B1 = 193 - 480 inch Stroke Single Spring

B2 = 193 - 480 inch Stroke Double Spring

C = 481 - 1200 inch Stroke

Active Stroke in Inches

12

S

X

Initial Cable Lead in Inches

First 72 inches of intial lead is no charge. Cable lead

above 72 inches an additional charge per inch.

Leave blank if no initial cable lead required.

Sensor Type

S = Single-turn Resolver

M = Multi-turn Resolver

P1 = Single-turn Potentiomenter

P2 = Multi-turn Potentiometer

E1 = Provision for an Incremental Encoder*

E2 = Provision for an Absolute Sensor*

DN = Single-turn Resolver with DeviceNet Interface

CO = 4 - 20mA Output (Resolution is 1,000 points of total stroke)

* In instances where provisions for a customer supplied sensor are required, the following points must be covered:

A. A detailed dimension drawing of the sensor to be coupled must be supplied

B. A custom dimension/approval drawing will be made prior to manufacturing.

C. Special gearing of sensor may require an additional charge.

Options

X = None

Part Numbering

Description

Part Number

Horizontal

PSD0102600

PSD0102500

Vertical

Part Number

SD0414600L__

Description

Part Number

Spring motor for A1&

A2 Style Units

Spring motor for B &

C Style Units

M0352900

SD039220

Description

Part Number

Resolver & Mating

Connector

SD0308900

Points to note when ordering a linear cable reel sensor:

1. Hardware types determine the maximum capable stroke of each style. The actual stroke is customer specified. Three

initial wraps minimum remain on cable drum after the stroke length is reached. Pulling the cable out to its physical

maximum length may damage the unit.

2. Standard gearing of single-turn sensors is such that the active stroke of the cable reel will rotate the sensor 350 degrees.

Multi-turn sensors will rotate the maximum number of turns over the active stroke. Requests for gearing other than the

above must be called out clearly on order.

3. Mounting of customer supplied sensors is done in the most expedient way possible. Special mounting requirements

must be specified clearly on order.

Sheave Assemblies

Resolver

Cable Assembly

Replacement Spring Assembly