0 care and maintenance – ARI Armaturen Liquid PN25 EN User Manual

Page 8

Page 8

Rev. 0040807002 0405

Operating and installation instructions

Liquid return temperature limiter

7.0 Care and maintenance

Maintanance and maintenance-intervals have to be defined by the operator according to

the requirements.

7.1 Cleaning / replacing controller assembly

(refer to Fig. 1 page 4 - Fig. 3 page 6)

- Depressurise unit.

- Release and disassemble screw cap (Pos. 6).

- Unscrew bimetallic controller (Pos. 24).

- Clean body (Pos 1), screw cap (Pos. 6) and all seal faces.

- Clean bimetallic controller (Pos. 24) and check sealing parts at seat (Pos. 24.1). If the

operator thinks there are unwarranted leakages we recommend checking the controller

setting or replacing the complete bimetallic controller (Pos. 24).

- Screw in and tighten bimetallic controller (Pos. 24) (see 7.3).

- Assemble screw cap (Pos. 6) (see 7.3).

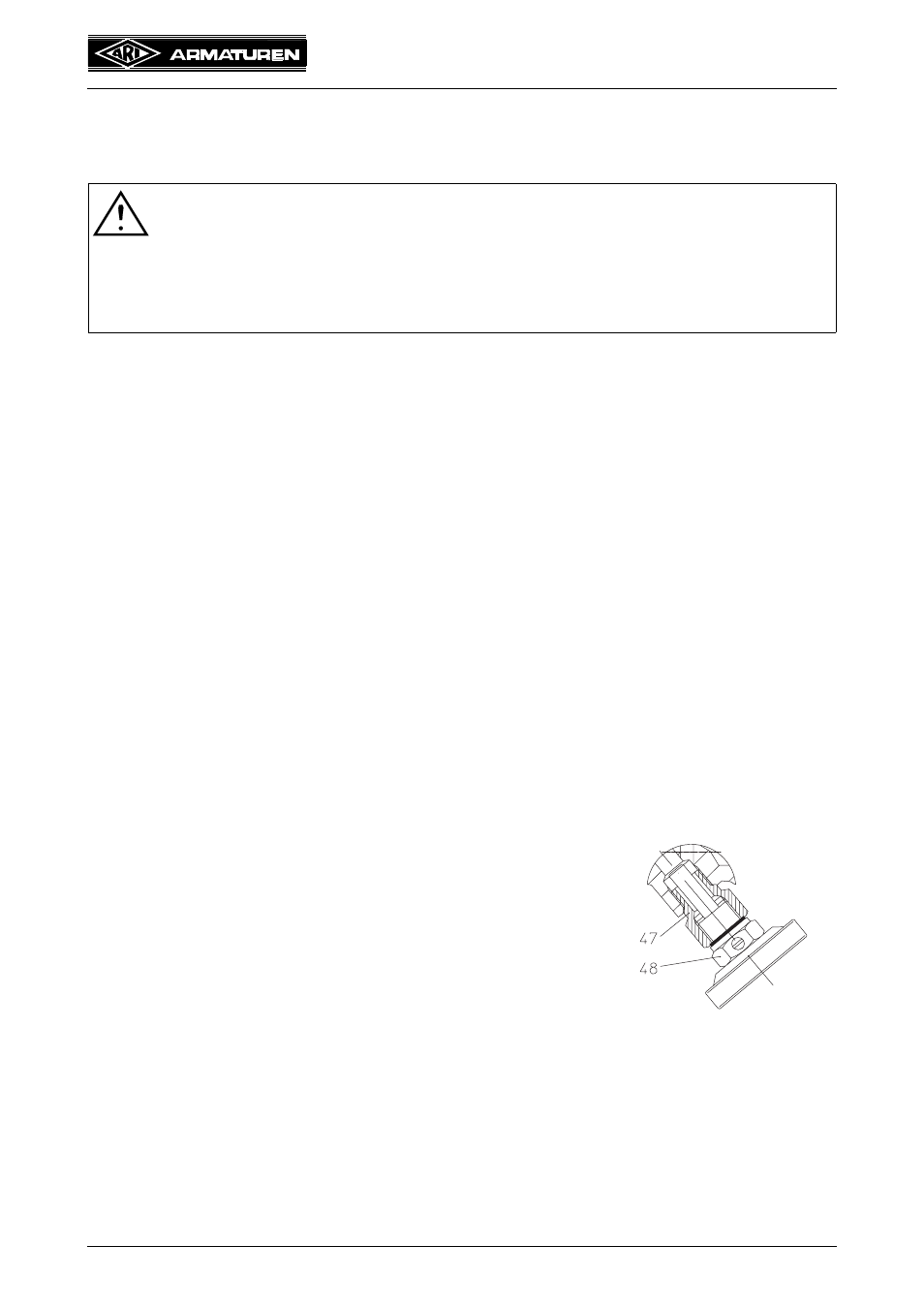

Version with plug-in thermometer:

- Unscrew thermometer adapter (Pos. 47) with thermometer (Pos. 48) and clean parts/seal

faces.

- Fit thermometer adapter (Pos. 47), making sure seal faces are clean.

- Tighten thermometer adapter (Pos. 47) (see 7.3).

- Assemble in reverse order (see 7.3).

7.2 Option thermometer adapter with thermometer

ATTENTION !

- refer to item 10.0 and 11.0 prior to dismantling and repair work!

- refer to item 6.0 before restarting the plant !

Prior to installation, threads and seal faces should be coated with temperature-

stable lubricant (e.g. “OKS Anti-Seize Paste” white/metal-free for PN 16-40 or

“Rivolta” lubricant and parting agent silver for PN 63 onwards).

It is possible to monitor the process temperature in situ with

the thermometer (Pos. 48).

Note section 7.3 when installing and operating.

Fig. 4