0 care and maintenance – ARI Armaturen CODI B PN63 EN User Manual

Page 8

Page 8

Rev. 0040807006 1404

Operating and installation instructions

CODI

®

S/B -

Condensate collection / steam distribution

7.0 Care and maintenance

Maintanance and maintenance-intervals have to be defined by the operator according to

the requirements.

7.1 Disassembling/assembling complete shut-off valve assembly

(see Fig. 2 page 5 - Fig. 3 page 5)

- Open spindle (Pos. 11) fully as far as the stop.

- Unscrew shut-off valve assembly (Pos. 8) from body (Pos. 1) by rotating to the left.

- Remove graphite insert (Pos. 7).

- Unscrew hollow-core screw (Pos. 14) using AWH assembly spanner.

- Remove seat (Pos. 3).

- Assemble in reverse order (see 7.5).

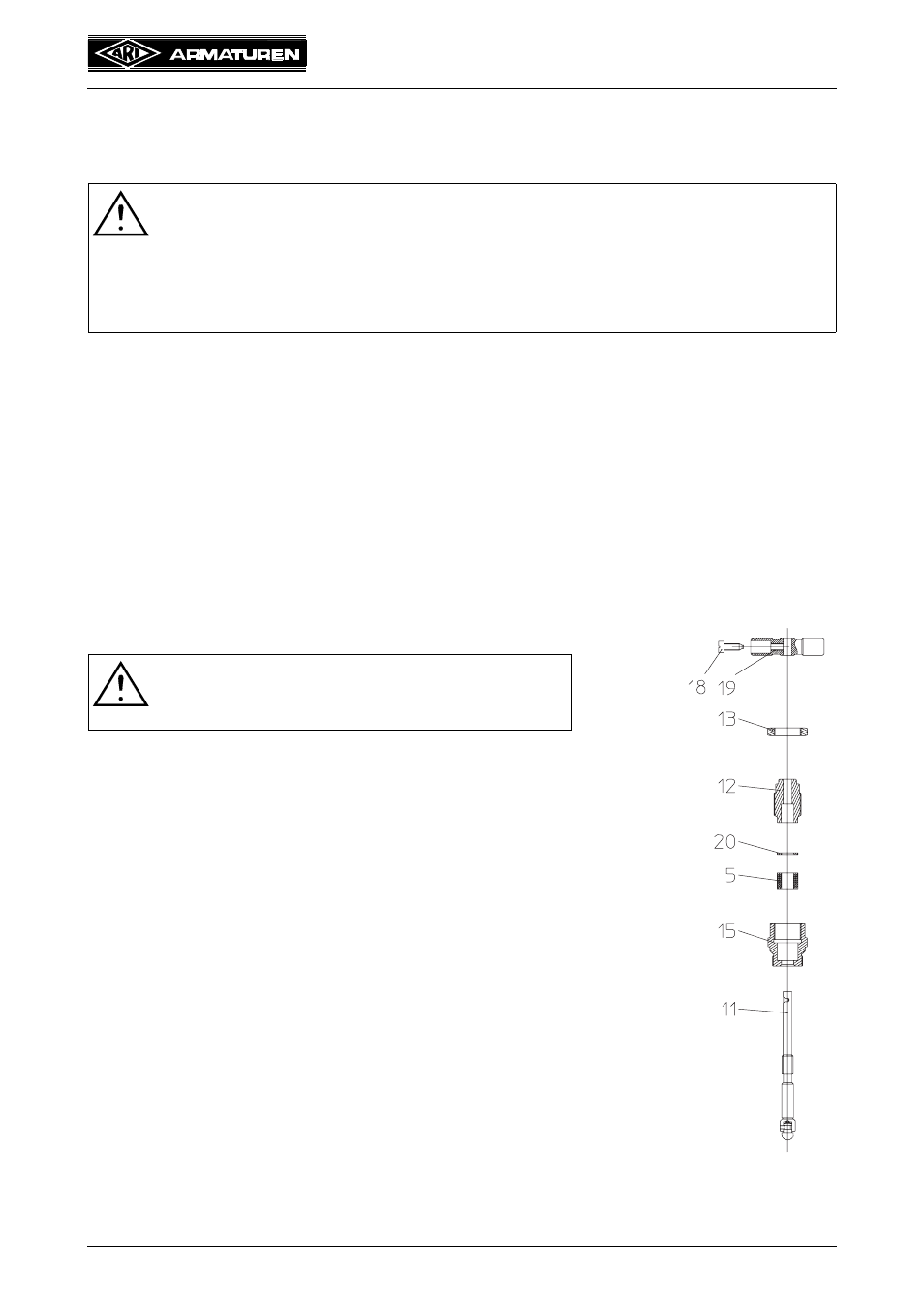

7.2 Replacing the packing rings (CODI

®

S)

- Dismantle shut-off valve assembly (Pos. 8) as described in 7.1.

- Rotate spindle (Pos. 11) in closing direction.

- Slacken cheese-head screw (Pos. 18).

- Pull handle (Pos. 19) away from spindle (Pos. 11).

- Release lock nut (Pos. 13).

- Unscrew threaded bush (Pos. 12).

- Withdraw spindle (Pos. 11) downwards from threaded bush (Pos. 12).

- Dismantle cover ring (Pos. 20) and packing rings (Pos. 5).

- Clean packing chamber and spindle surface.

- Push spindle (Pos. 11) into screw fitting (Pos. 15) and fit new packing

rings (Pos. 5).

- Assemble in reverse order (see 7.5).

ATTENTION !

- refer to item 10.0 and 11.0 prior to dismantling and repair work!

- refer to item 6.0 before restarting the plant !

Prior to installation, threads and seal faces should be coated with temperature-

stable lubricant (e.g. “OKS Anti-Seize Paste” white/metal-free for PN 16-40 or

“Rivolta” lubricant and parting agent silver for PN 63 onwards).

ATTENTION !

It is vital to avoid damage to spindle surface and

packing chamber surface.

Fig. 4