3 options, 4 function testing of diaphragm capsule, Os. 24.17) (see 7.4) – ARI Armaturen CONA SC-Plus PN40 EN User Manual

Page 11: Operating and installation instructions cona, Sc/sc-plus - ball float steam traps 7.3 options

Rev. 0040805003 3409

Page 11

Operating and installation instructions

CONA

®

SC/SC-Plus - Ball float steam traps

7.3 Options

(refer to Fig. 2 page 4 and Fig. 10 page 11)

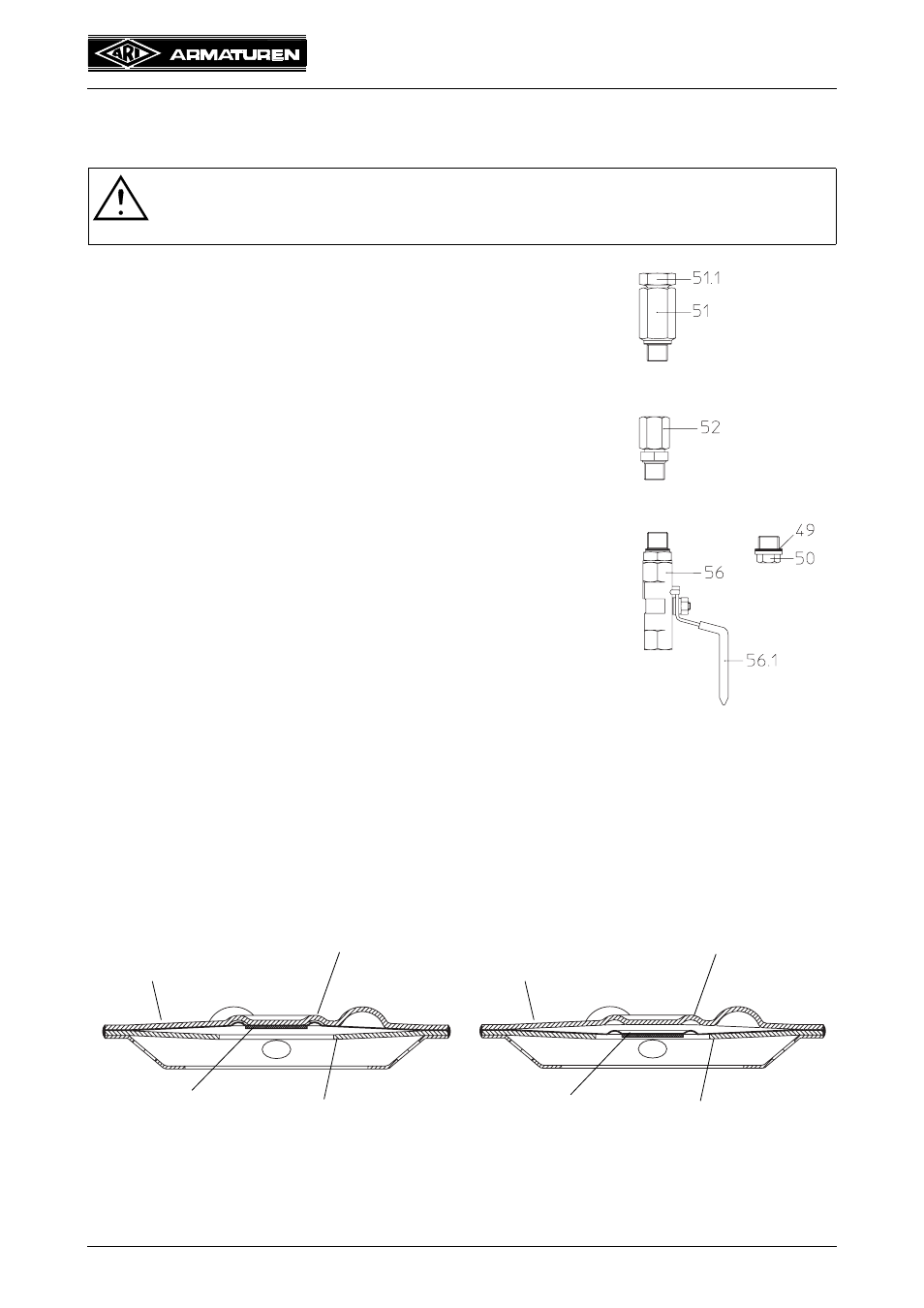

7.4 Function testing of diaphragm capsule

With a dry, cold diaphragm capsule the diaphragm surface with the circular bead must rest

against the top part of the wall (with 3 knobs), capsule is open (see Fig. 11).

If it rests against the bottom part of the wall, this is a sign that it is defective and must be

replaced with a new diaphragm capsule (see Fig. 12).

It should also be replaced if there are visible deformations on the surface.

ATTENTION !

Escape of hot medium under pressure!

Observe item 2.2!

Accumulated inert gases can be discharged to the

environment with the manual air vent valve (pos. 51) by

opening the pressure screw (Pos 51.1).

It is possible to return the accumulating gases to the system by

connecting a pressure compensation line to the union

(pos. 52).

In Series 634 the residual condensate can be drained by way

of the drain plug (pos. 50) (see 5.1)

(standard in series 636/635).

Accumulated dirt and condensate can also be removed from

the hood (pos. 16) using a ball valve (pos. 56).

During operation it is imperative to observe general working

safety conditions and possibly fit devices to guard against

scalding/injury.

Note section 7.5 when installing and operating the option.

Fig. 10

Fig. 11: Capsule OPEN

Fig. 12: Capsule CLOSED

top part of wall

bottom part of wall

diaphragm surface

capsule type

top part of wall

bottom part of wall

diaphragm surface

capsule type