0 troubleshooting, 0 troubleshooting table, 0 troubleshooting 9.0 troubleshooting table – ARI Armaturen BR015-ZIVA-G EN User Manual

Page 13: Operating and installation instructions zesa, Gesa, Ziva, Z / ziva

Rev. 0040201000 0511

Page 13

Operating and installation instructions

ZESA

®

/ GESA

®

/ ZIVA

®

-Z / ZIVA

®

-G

8.0 Troubleshooting

In the event of malfunction or faulty operating performance check that the installation and

adjustment work has been carried out and completed in accordance with these Operating

Instructions.

If malfunctions cannot be eliminate with the help of the following table

“9.0 troubleshooting table”, the supplier or manufacturer should be consulted.

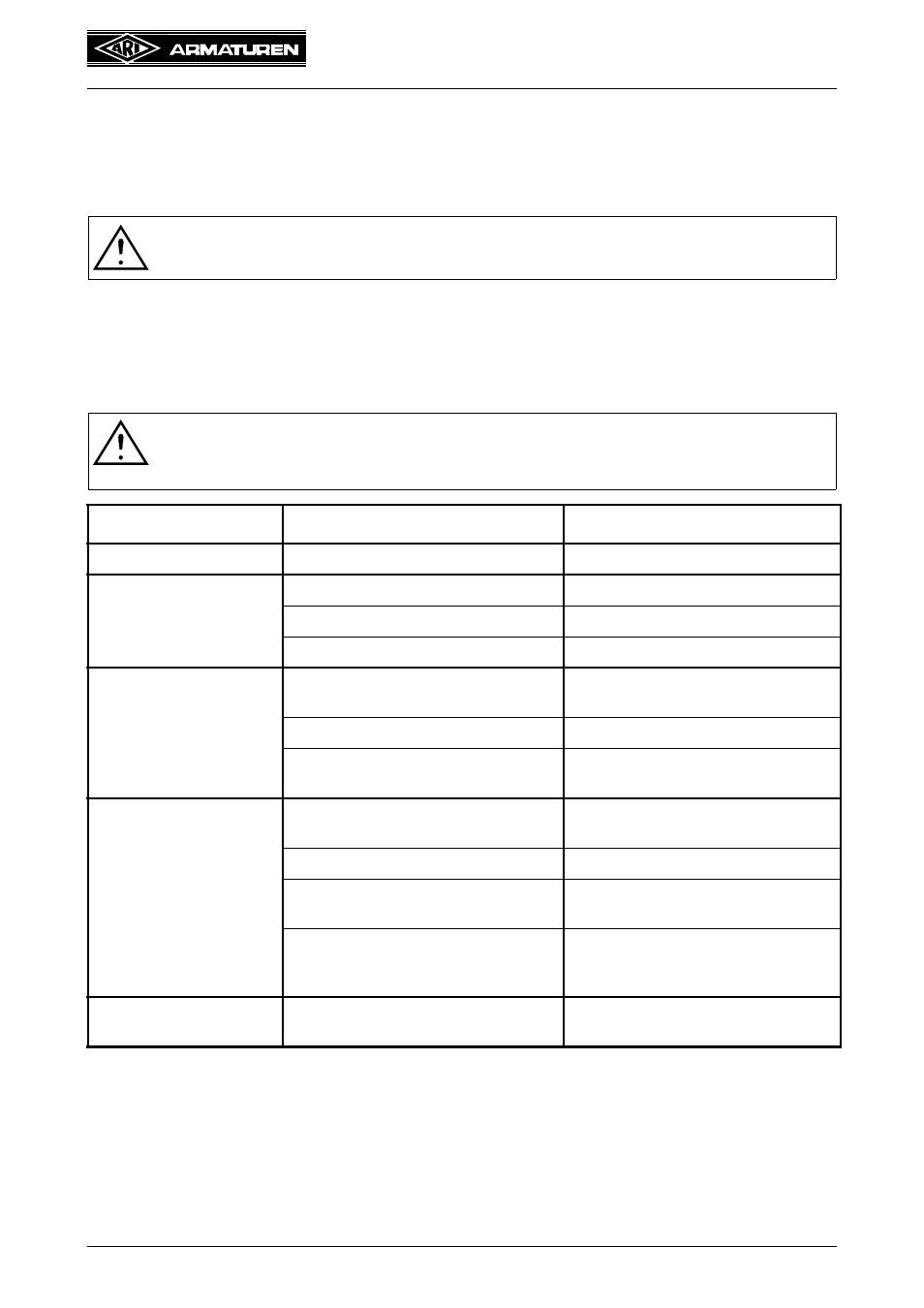

9.0 Troubleshooting table

-

ATTENTION !

It is essential that the safety regulations are observed when identifying faults.

ATTENTION !

- read point 10.0 and 11.0 prior to dismantling and repair work!

- read point 6.0 before restarting the plant !

Fault

Possible cause

Corrective measures

No flow

Valve closed.

Open valve.

Little flow

Valve not sufficiently open.

Open valve.

Strainer sieve clogged.

Clean / replace sieve.

Piping system clogged.

Check piping system.

Valve is impossible or diffi-

cult to open or close

Service conditions (e.g. medium, tem-

perature) outside permissible limits.

Replace valve. Consult supplier or

manufacturer.

Power failure.

Check power supply.

Wrong direction of rotation.

Turn in correct direction

(clockwise for opening).

Valve leaking

Not properly closed.

Close valve properly or readjust limit

switch/stop screw.

Pressure difference too high.

Check plant.

Medium contaminated.

Clean valve.

Install strainer sieve upstream of valve.

Lining/collars (Fig. 1-2, item 2) or valve

disc (Fig. 1-2, item 3) damaged by for-

eign bodies or medium

Replace valve. Consult supplier or

manufacturer.

Valve with locking device

cannot be opened

Locking device tightened.

Slacken locking device.