1 removing the handwheel, 2 fitting the hand wheel and display, 2 mounting the handwheel and display in – ARI Armaturen ASTRA DN250-400 EN User Manual

Page 7: Lagged pipe runs

Rev. 0040105004 0212

Page 7

Operating and installation instructions

ASTRA

®

- Planners / construction companies or operators are responsible for positioning and

installing products.

- The valves are designed for application, not influenced from weather.

- For application outside or in adverse environments like corrosion-promoting conditions

(sea water, chemical vapours, etc.), special constructions or protective measures are

recommended.

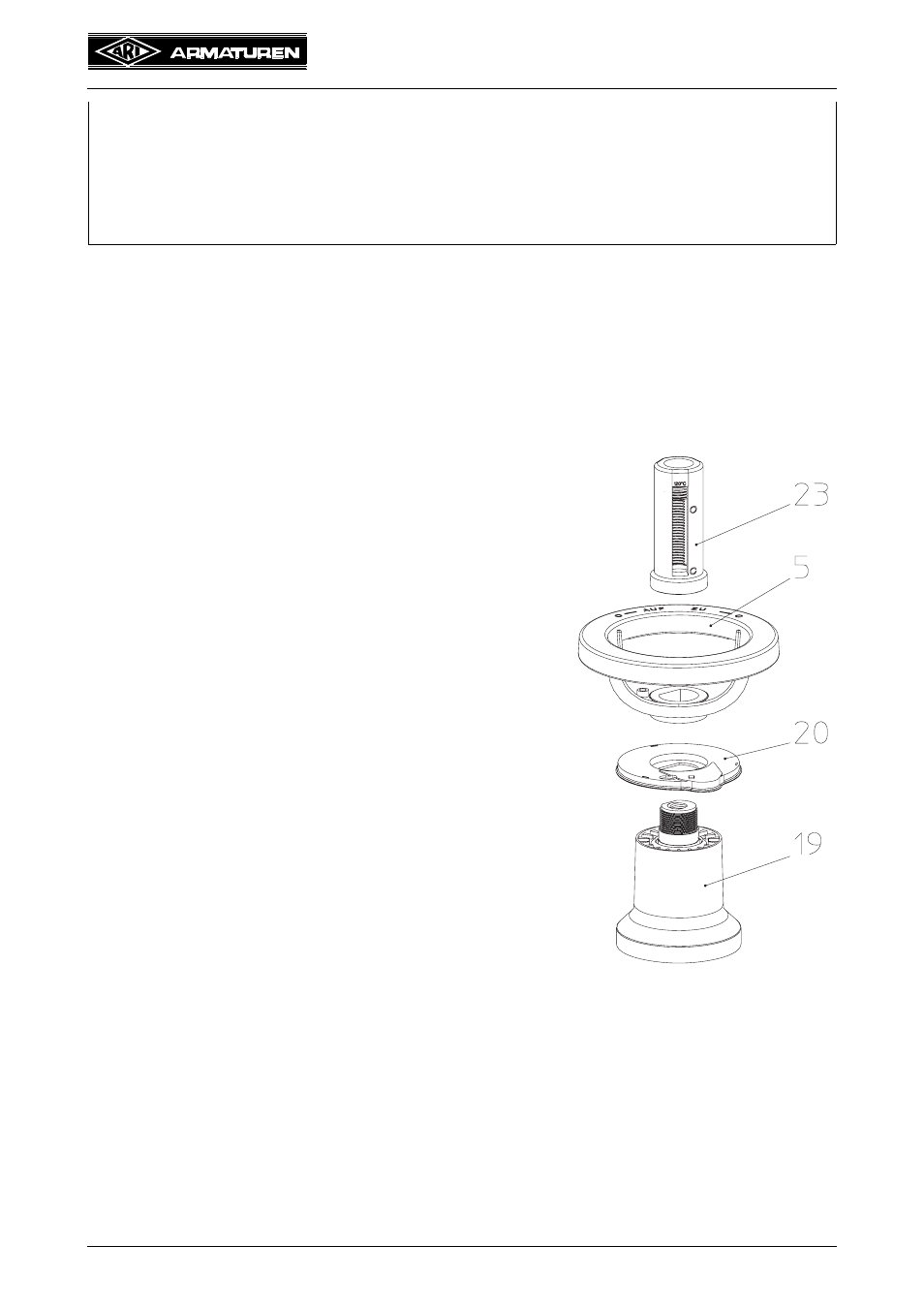

5.2 Mounting the handwheel and display in

lagged pipe runs

5.2.1 Removing the handwheel

1. Close the valve by hand (pos. 5) (“0” position).

2. Unscrew the cap (pos. 23).

3. Lift off the handwheel (pos. 5) and the digital display

(pos. 20).

4. Insulation diameter:

DN 15- 50 = 60 mm

DN 65-200 = 87 mm

Do not remove the insulation cap.

5.2.2 Fitting the hand wheel and display

1. Set the digital display (pos. 19) in place, regard “0”

position.

2. Set the handwheel (pos. 5) in place.

3. Screw on the cap (pos. 23): DN 15- 50 = 11 Nm

DN 65-200 = 15 Nm

- Reference for isolation: If media-temperatures < ambient temperatures - ask

manufacturer.

- It is forbidden to heat the valve to above its service temperature (see data

sheets), for instance by welding, grinding, etc.

- To ensure that the valves function correctly, the pipe run should be straight for

at least 6 x DN upstream and 2 x DN downstream of the valve.

Fig. 5