Application, Multiple unit stacking, Ordering information – Red Lion P48 User Manual

Page 5: Water processing application, Accessories

5

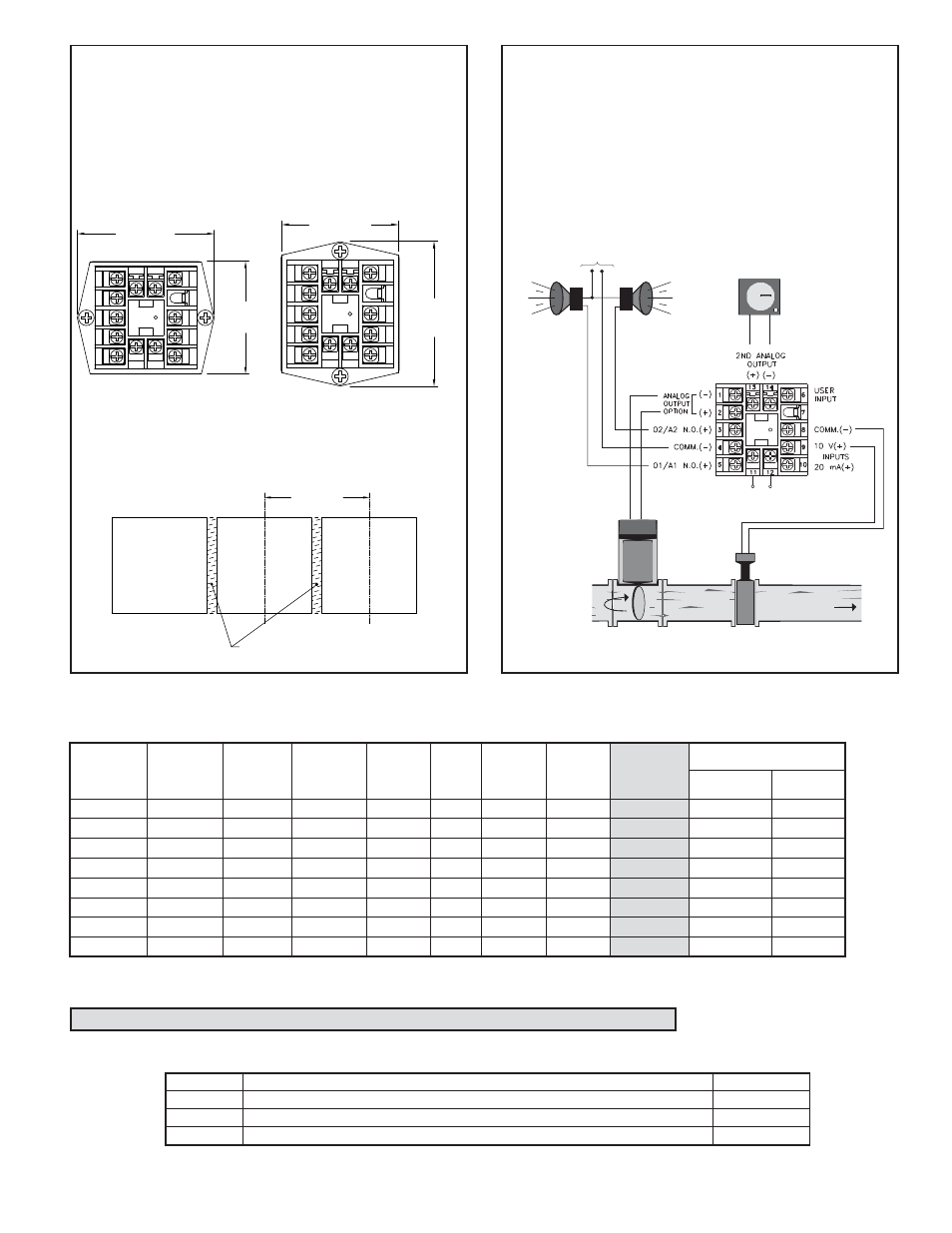

APPLICATION

WATER PROCESSING APPLICATION

A city water company needs to maintain a steady flow of water for their

customer needs. They have an existing 0 to 10 VDC flow transmitter to

measure the water flow. They need to control the water flow, have a high and

low alarm, and keep a recorded chart of the flow for later reference. The Main

Linear DC output of the P48 can be used to control the position of water

output values per the desired flow setpoint value. The P48 relay outputs can

be programmed to give a high flow alarm and a low flow alarm. With the

Second Linear DC output model, the flow measurement to the P48 can be

converted from 0-10 V to 4-20 mA and retransmitted to a 4-20 mA chart

recorder.

CHART

RECORDER

HIGH

ALARM

LOW

ALARM

WATER FLOW

ALARM

POWER

+

-

CONTROL

VALVE

FLOW

SENSOR

UNIT POWER

MULTIPLE UNIT STACKING

The P48 is designed for close spacing of multiple units. Units can be

stacked either horizontally or vertically. For vertical stacking, install the panel

latch with the screws to the sides of the unit. For horizontal stacking, the panel

latch screws should be at the top and bottom of the unit. The minimum

spacing from center line to center line of units is 1.96" (49.8 mm). This

spacing is the same for vertical or horizontal stacking.

Note: When stacking units, provide adequate panel ventilation to ensure that

the maximum operating temperature range is not exceeded.

1

2

3

4

5

6

7

8

9

10

13

14

12

11

2.39 (60.7)

MAX.

1.96 (49.8)

MAX.

PANEL LATCH INSTALLED FOR

VERTICAL UNIT STACKING

HORIZONTAL UNIT STACKING

PANEL LATCH INSTALLED FOR

MAX.

2.39 (60.7)

MAX.

1.96 (49.8)

1

2

3

4

5

6

7

8

9

10

13

14

12

11

1.96 (49.8)

MIN.

IF NEMA 4 IS NOT REQUIRED,

THIS PANEL MATERIAL MAY BE REMOVED.

PANEL

CUT-OUT

STANDARD

PANEL CUT-OUT SPACING FOR MULTIPLE UNIT STACKING.

HORIZONTAL ARRANGEMENT SHOWN.

(Terminal assignments are model number dependent.)

ORDERING INFORMATION

Options and Output Boards are factory configured per the part number specified. Part numbers without replacement output boards listed must be returned

to the factory for output board replacement.

DEDICATED

MAIN CONTROL

O1 OUTPUT

MAIN CONTROL

O1 or

A1(ALARM 1)*

DEDICATED

ALARM 1

A1 OUTPUT

A2 (ALARM 2)

OR O2

(SECONDARY)*

REMOTE

SETPOINT

INPUT @

RS485 @

MAIN

ANALOG

OUTPUT** @

SECOND

ANALOG

OUTPUT** @

PART NUMBERS

85 to 250 VAC

18-36 VDC/24 VAC

REPLACEMENT

OUTPUT

BOARD

YES

P4800001

P4800011

NA

Relay

P4810000

P4810010

RBD48100

Relay

Relay

YES

P4810101

P4810111

NA

Relay

Relay

YES

YES

P4810105

P4810115

NA

Relay

Relay

YES

YES

P4810107

P4810117

NA

Relay

Relay

YES

YES

P481010A

P481011A

NA

Relay

Relay

Relay

P4811100

P4811110

RBD48111

Relay

Relay

Relay

YES

P4811102

P4811112

RBD48111

* This output is programmable as either Control (PID) or as an Alarm.

** These part numbers are jumper and program selectable for either a current or a voltage Linear DC output.

@ These part numbers are equipped with a second setpoint.

MODEL NO.

DESCRIPTION

PART NUMBERS

ICM5

ICM4

SFCRM

Three Way Isolated RS232/RS485 Serial Converter Module

RS232/RS485 Serial Converter Module

ICM50000

ICM40030

SFCRM

ACCESSORIES

Option Boards are installed at the factory for the appropriate models. These boards are only needed for field replacement.

Crimson 2 PC Configuration Softwware for Windows 98, ME, 2000 and XP (for RS485 models)

*Crimson Software is available for download from http://www.redlion.net