Setup, Installation – Red Lion APMR User Manual

Page 3

3

SETUP

1. Adjust the dials on the APMR to

the following settings:

a. Under Voltage to minimum

(CCW)

b. Under Voltage Delay to

minimum (CCW)

c. % Unbalanced to maximum

(CW)

2. Connect input wire from the

fused 3 phase line voltage to

Terminals 7 (L1), 9 (L2), and 11

(L3). In Wye systems,

connection to neutral wire is not

required. Do not wire output

contacts until Step 9.

3. TURN POWER ON. When the internal relay energizes, and the Red LED

glows green, the phase sequence is correct and the voltages on all three

phases are above the minimum under voltage setting.

a. If the internal output relay does not energize, and the LED stays red, TURN

POWER OFF and swap any two (2) of the three (3) input wires. This

corrects the phase sequence if the monitor was connected in reverse rotation.

Note: Insure that the motor is wired for correct rotation.

4. Select the proper under voltage trip point. (This is the dial marked Under

Voltage.) The under voltage setting should be the same as the minimum

operating voltage for the equipment to be protected.

Note: If the recommended setting is not known, turn the Undervoltage

adjustment knob CW until the relay de-energizes and the LED glows red.

Turn the knob CCW until the relay energizes and the LED glows green.

This procedure assumes that the line voltages are at an acceptable level

when the adjustments are made.

5. Set the Under Voltage Delay to the desired value. This is the maximum time

period that an under voltage condition can exist before de-energizing the

internal relay. The exact value of the delay depends on the type of equipment

being protected and the quality of the available three phase power. A setting

too low, will cause unnecessary interruptions due to momentary dips in the

line voltage. On the other hand, if the time delay is too long, damage to the

equipment can occur before a legitimate under voltage condition is detected.

Three phase motors have a starting current that is many times higher than

the normal full load current but lasts for only a few seconds. Setting the

delay slightly longer than the duration of this inrush period will prevent the

APMR from being tripped due to a low voltage condition caused by the

starting current.

Note: The under voltage delay applies only to under voltage conditions.

Exceeding the phase unbalance trip setting or a phase loss will de-

energize the relay instantly regardless of the delay setting.

6. Phase Unbalance setting. Maximum permissible unbalance and phase

voltages that most three phase powered equipment can tolerate are very

seldom specified. In most locations, three phase voltages typically are not

perfectly balanced. Use your own discretion when setting this value. Too low

of a setting (CCW) can cause unnecessary tripping. Too high of a setting

(CW) does not provide adequate protection.

An alternative procedure is to turn the Unbalance adjustment CCW until the

relay de-energizes and the LED turns red. Turn the knob CW until the relay

energizes and the LED turns green.

Note: This procedure assumes that the line voltages are sufficiently balanced

when the adjustments are made. % Voltage Unbalance is defined by NEMA

as: [(Maximum Deviation From Average Voltage/Average Voltage) X 100]

where Average Voltage = (L1 + L2 + L3)/3.

Note: NEMA recommends not to operate motors with a phase unbalance

greater than 5%.

7. When the phase sequence is correct and the line voltages are within preset

limits, the internal relay of the APMR will energize. The LED indicator

glows green to show a normal condition.

8. TURN POWER OFF. Refer to the wiring diagram for proper output contact

connections.

9. After proper connections are made, TURN POWER ON. The internal relay

energizes allowing the monitored load to become active.

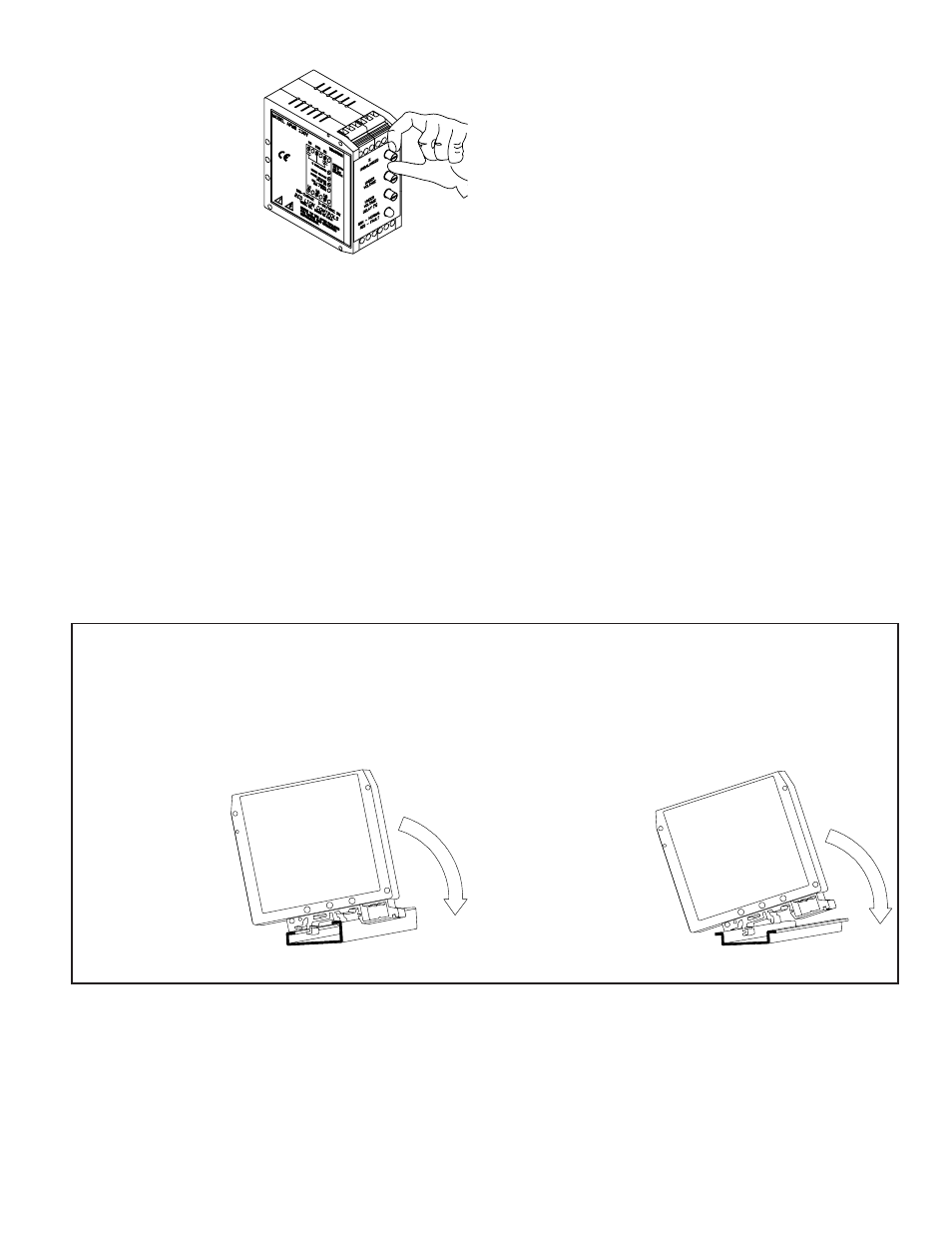

G Rail Installation

To install the APMR on

a “G” style DIN rail,

angle the module so that

the upper groove of the

“foot” catches under the

lip of the top rail. Push the

module toward the rail

until it snaps into place.

To remove a module from

the rail, push up on the

bottom of the module

while pulling out away

from the rail.

T Rail Installation

To install the APMR on a

“T” style rail, angle the

module so that the top

groove of the “foot” is

located over the lip of the

top rail. Push the module

toward the rail until it snaps

into place. To remove a

module from the rail, insert

a screwdriver into the slot on

the bottom of the “foot”, and

pry upwards on the module

until it releases from the rail.

INSTALLATION

The unit is equipped with a universal mounting foot for attachment to standard DIN style

mounting rails, including G profile rail according to EN50035 - G32 , and top hat (T) profile rail

according to EN50022 - 35 x 7.5 and 35 x 15.

The unit should be installed in a location that does not exceed the maximum operating

temperature and provides good air circulation. Placing the unit near devices that generate

excessive heat should be avoided.