Standard performance – Power Jacks E-Series - Machine User Manual

Page 9

www.powerjacks.com

9

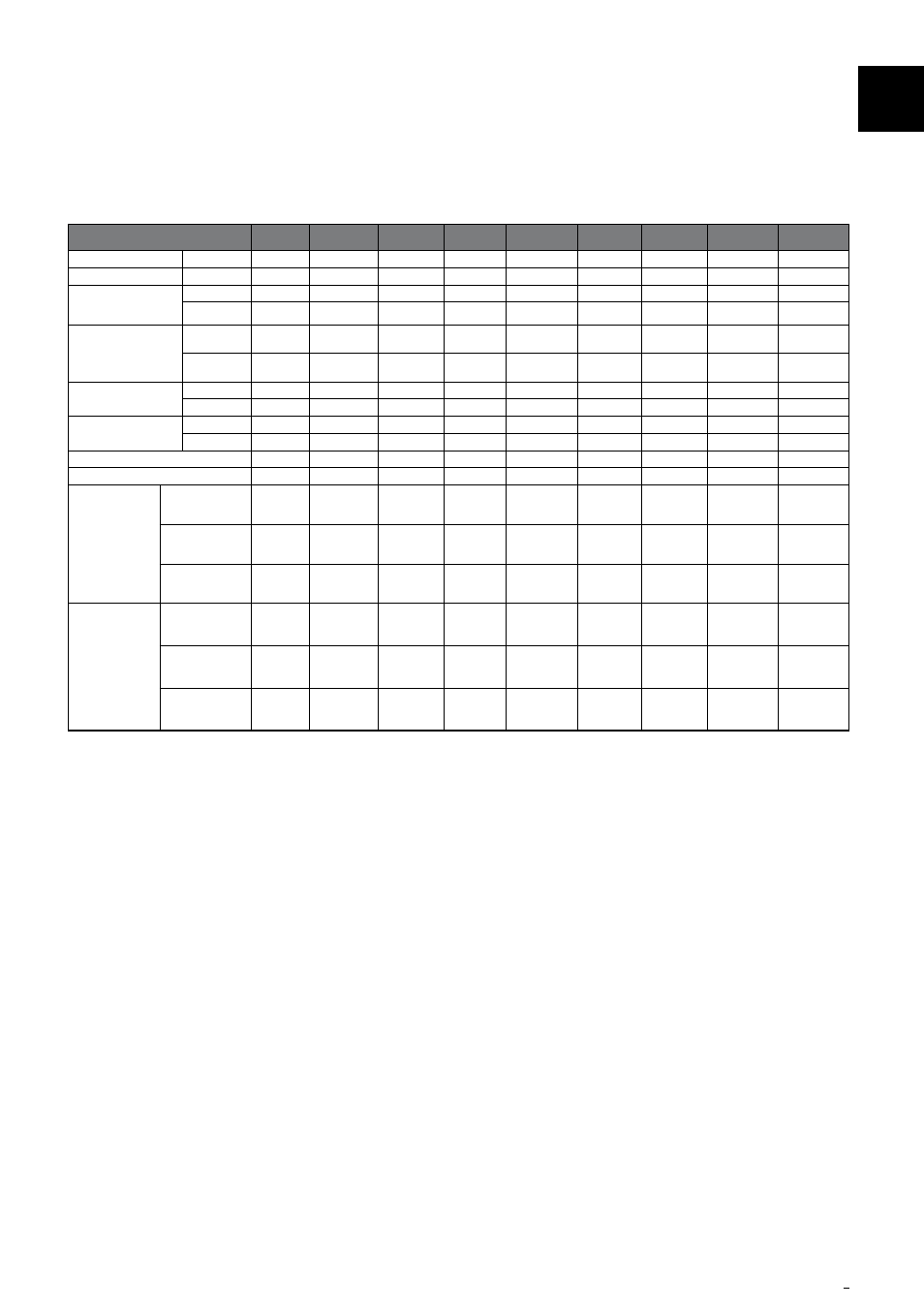

Model

E2625

E2501

E1802

E1805

E1810

E1820

E1830

E1850

E18100

Capacity

kN

5

10

25

50

100

200

300

500

1000

Lifting Screw

NOTE

1

mm

16 x 3

20 x 5

30 x 6

40 x 9

55 x 12

65 x 12

95 x 16

120 x 16

160 x 20

Gear ratios

Option 1

5:1

5:1

6:1

6:1

8:1

8:1

102/3:1

102/3:1

12:1

Option 2

20:1

20:1

24:1

24:1

24:1

24:1

32:1

32:1

36:1

Turn of worm for travel

of lifting screw

Option 1

5 for 3mm

1 for 1mm

1 for 1mm

1 for

1.5mm

1 for 1.5mm

1 for 1.5mm

1 for 1.5mm

1 for 1.5mm

3 for 5mm

Option 2

20 for

3mm

4 for 1mm

4 for 1mm

4 for

1.5mm

2 for 1mm

2 for 1mm

2 for 1mm

2 for 1mm

9 for 5mm

Max. Input power (kW)

Option 1

0.25

0.375

1.5

3

3.75

3.75

6

11.25

18.5

Option 2

0.12

0.19

0.375

0.55

1.125

1.125

1.9

4.5

8.25

Start up torque at full

load (Nm)

NOTE 2

Option 1

2.5

6.8

19.8

56

115.9

263.8

480

904

2025

Option 2

1.1

3

8.7

25.5

60.5

137

284

504

1119

Weight (kg) - stroke = 150mm

1.03

2.27

8.17

15.88

24.72

45

86

195

553

Weight (kg) per extra 25mm

0.073

0.13

0.21

0.32

0.57

0.86

1.58

2.49

4.31

Option 1

Gear Ratio

5

5

6

6

8

8

10 2/3

10 2/3

12

Screw Jack Static

Efficiency

0.189

0.233

0.201

0.213

0.206

0.181

0.149

0.132

0.131

Screw Jack

Dynamic Efficiency

0.252

0.306

0.264

0.281

0.272

0.242

0.205

0.181

0.178

Option 2

Gear Ratio

20

20

24

24

24

24

32

32

36

Screw Jack Static

Efficiency

0.107

0.130

0.115

0.117

0.132

0.116

0.084

0.079

0.079

Screw Jack

Dynamic Efficiency

0.160

0.194

0.167

0.172

0.190

0.169

0.128

0.120

0.123

Notes:

1.

All metric machine screws have a trapezoidal thread form.

2.

For loads of 25% to 100% of screw jack capacity, torque requirements are approximately proportional to the load.

3.

Efficiency values for standard grease lubricated worm gear box and lifting screw.

4.

All E-Series screw jacks have grease lubricated gearbox and lead screw as standard.

5.

For performance data for Anti-Backlash, Anti-Rotation (keyed) and other variants please consult corresponding catalogue.

Standard Performance

3