Maintenance – Power Jacks E-Series - Machine User Manual

Page 22

22

www.powerjacks.com

6

Maintenance

6.2

Regular Maintenance

Also refer to section 6.3

6.2.1 Lubrication Of The Screw Jack

6.2.1.1

The screw jacks are shipped packed with grease (unless otherwise called for) which should be

sufficient for one month of normal operation.

6.2.1.2

IMPORTANT NOTE – Lubricant suitability is dependent on duty cycle and ambient temperature.

However in general recommended lubricants in section 7 are suitable for operation in an

ambient temperature of -10ºC to +50ºC. If in doubt consult with Power Jacks prior to installation

and operation.

6.2.1.3

The maintenance engineer should establish a lubrication programme based on the screw jack’s

duty and use.

6.2.1.4

The lead screw requires a light grease film to be applied at Installation. The lead screw should

not be over greased.

6.2.1.5

Note excessive grease should be avoided.

6.2.1.6

It is recommended that the screw jack be fitted with bellows or covers to protect the exposed

screw from contamination from dirt and debris.

6.2.1.7

If the screw jack or its system is fitted with a brake ensure that under no circumstances

lubricant gets into the brake as this can cause brake failure due to loss of friction.

6.2.2 Lubrication Intervals - General

6.2.2.1

Regularly check and top up lubrication in the E-Series screw jack(s).

6.2.2.2

Refer to section 7 for recommended lubricants.

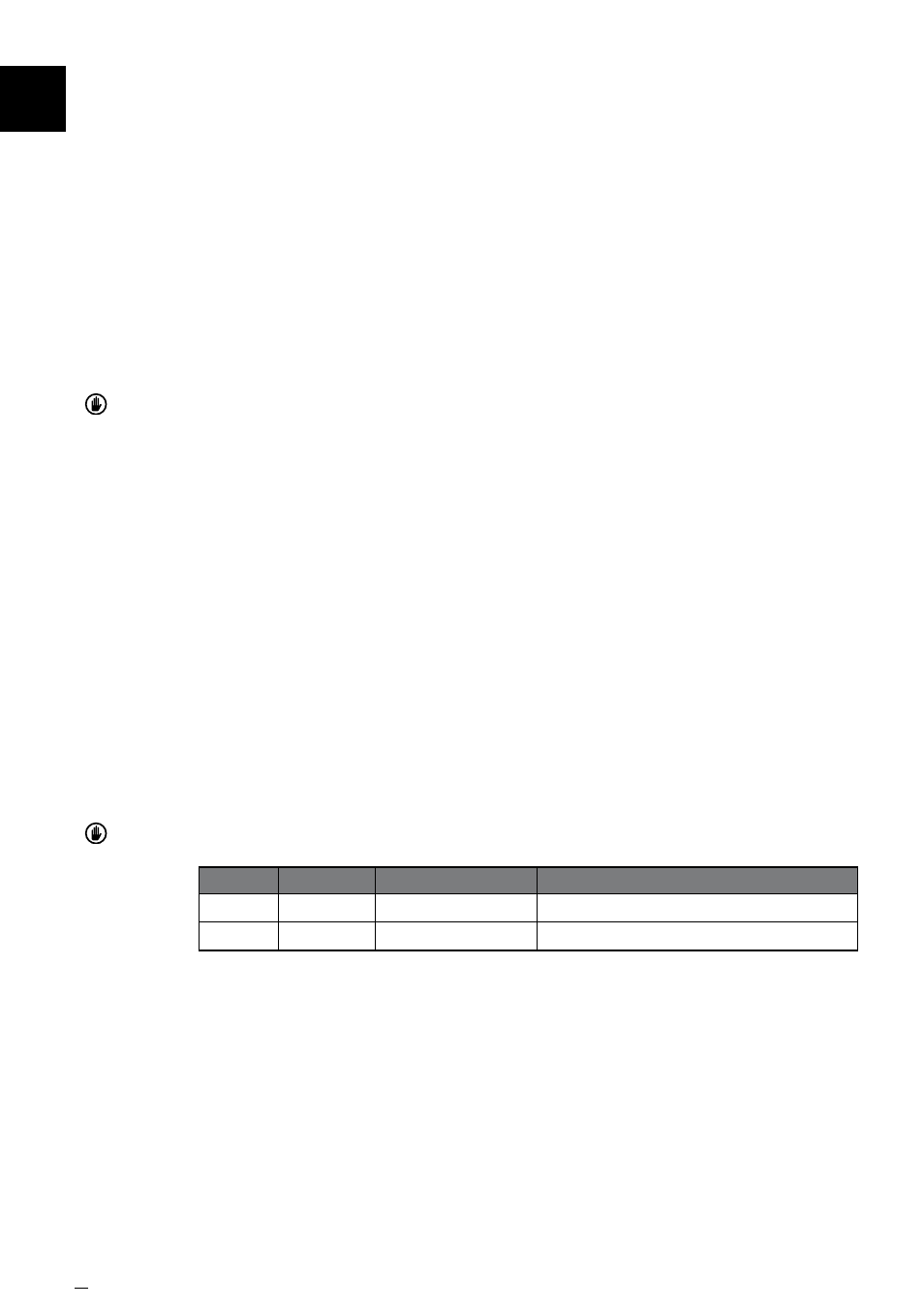

Item

Operation Type

Lubrication Interval

Grease Type

1

Normal

Check & lubricate as required

every 1 month

Extreme Pressure Grease or equivalent. Refer Section 7 Table 1

2

Arduous

Check & lubricate as required

every 1 week

Molybdenium disulphide grease or equivalent. Refer Section 7 Table 2

6.2.2.3

Rotating screw jacks are not supplied with lubricant on the lead screw as the screw thread is

exposed. Before operation suitable grease must be applied to the screw.

6.3

Check Unit Operational Performance

6.3.1

Remove dust / dirt / debris deposits from the unit(s).

6.3.2

Check that noise at constant load does not vary. Excessive vibration or noise can indicate wear of

a gear in a gearbox or failure of a bearing.

6.3.3

Check for lubricant leaks from the gaskets/seals, caps and casings.