Installation – Power Jacks E-Series - Machine User Manual

Page 11

www.powerjacks.com

11

4

Installation

4.2

General Instructions for fitting detachable ends on lead screws

In most circumstances the screw jack is delivered with the required end fitting assembled to the unit.

4.2.1

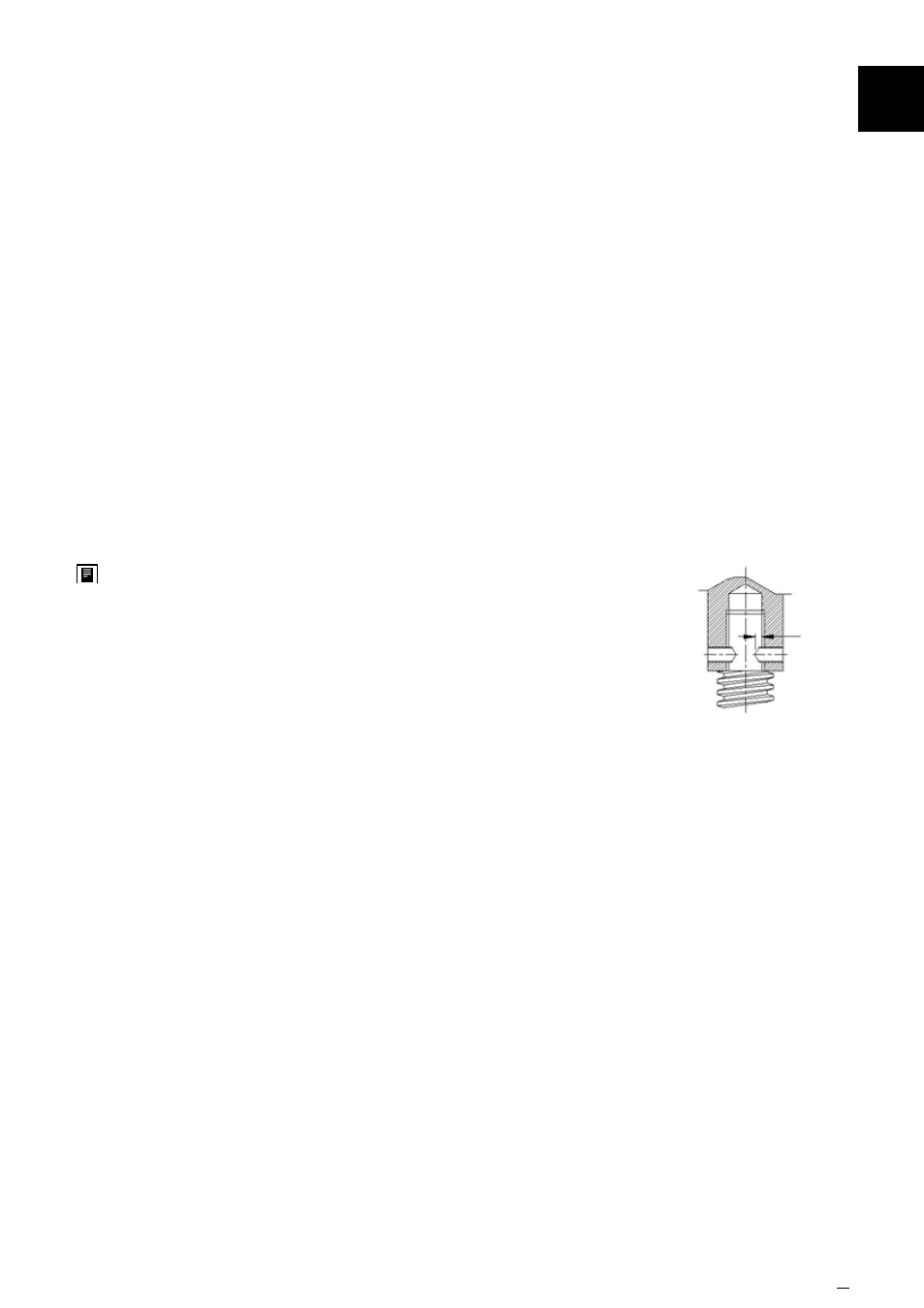

It is important that the detachable ends are securely fixed to the lead screws and the following

procedure should be adhered to.

4.2.2

Thread the detachable end on to the lead screw and tighten up as hard as possible without

damaging the components.

4.2.3

Select a twist drill which is a free fit in the tapped holes of the detachable end. Using these holes

as a drill guide, drill dimple only into the lead screw. Clean out swarf and remove detachable

end. Select another drill which matches the set screw diameter and, using the drill dimples as

a guide, drill into the lead screw a full diameter depth of 1mm below the root diameter of the

threads. Refit detachable end.

4.2.4

Fit the knurled point set screws (supplied with detachable ends) firmly in place ensuring that

point of set screws make contact with bottom of drill dimples. Secure the set screws with

chemical thread locking compound (e.g. Loctite).

4.2.5

If screw jacks with keyed lead screws are involved, and it is required to

line up the clevis flats or top plate holes, etc., in a fixed relationship

to the worm shaft centre line, it will be necessary to face the underside

of the detachable end to obtain the required relationship. This operation

should be done carefully as only a few hundredths of a mm (thousands

of an inch) removed from the attachment is equivalent to a fair amount

of rotational movement. After the correct relationship has been obtained

with the attachment firmly tightened up, proceed to install the screw jack

in accordance with this manual.

1mm deep

drill dimples