Close water systems, Thermal expansion – State GP6 50 HTPDT User Manual

Page 16

16

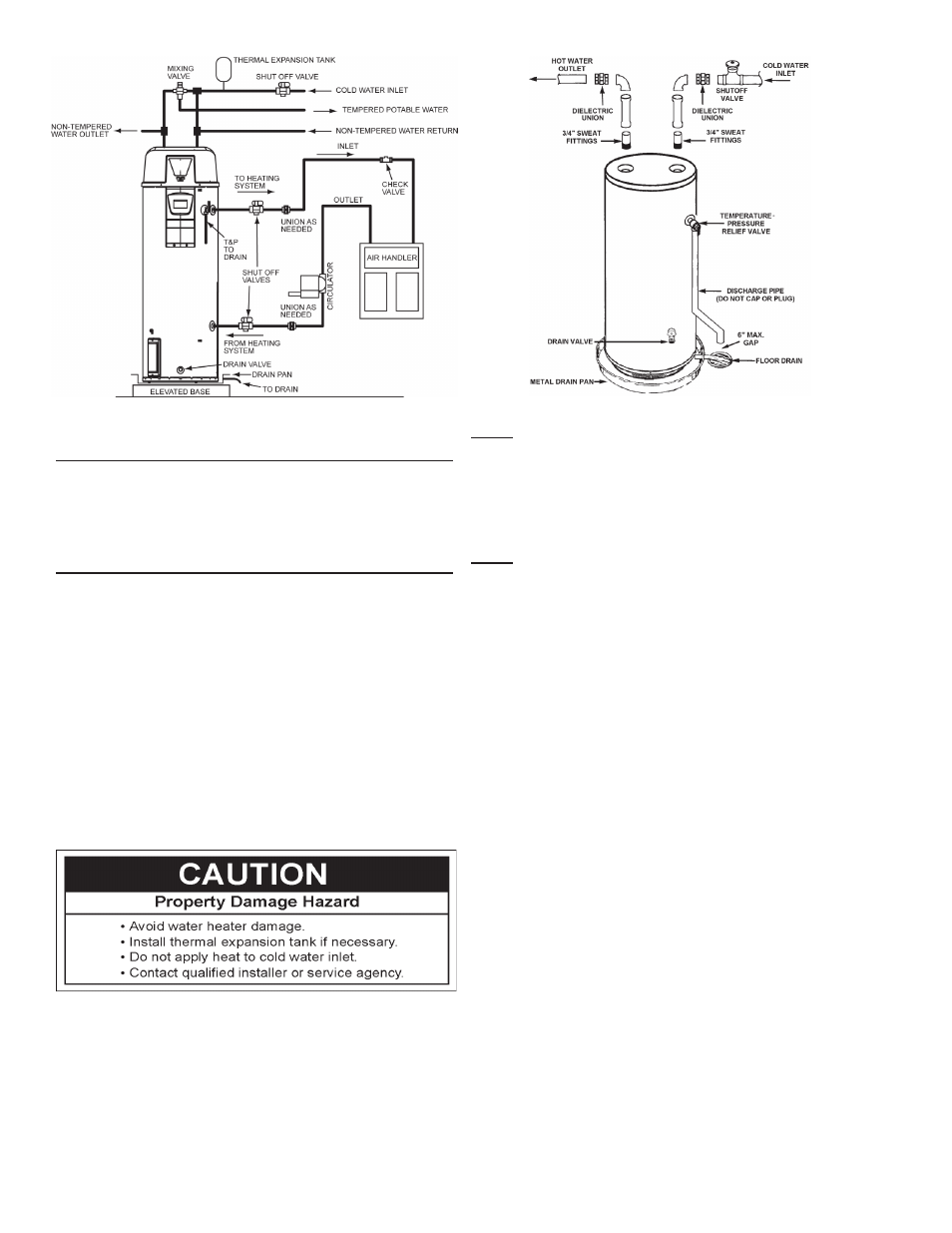

fIGure 9.

close water sYsteMs

Water supply systems may, because of code requirements or such

conditions as high line pressure, among others, have installed

devices such as pressure reducing valves, check valves, and back

flow preventers. Devices such as these cause the water system to

be a closed system.

therMal eXpansIon

As water is heated, it expands (thermal expansion). In a

closed system the volume of water will grow when it is heated.

As the volume of water grows there will be a corresponding

increase in water pressure due to thermal expansion. Thermal

expansion can cause premature tank failure (leakage). This

type of failure is not covered under the limited warranty.

Thermal expansion can also cause intermittent temperature-

pressure relief valve operation: water discharged from the

valve due to excessive pressure build up. This condition is

not covered under the limited warranty. The temperature-

pressure relief valve is not intended for the constant relief of

thermal expansion.

A properly sized thermal expansion tank should be installed

on all closed systems to control the harmful effects of thermal

expansion.

fIGure 10.

note: to protect against untimely corrosion of hot and cold

water fittings, it is strongly recommended that di-electric unions

or couplings be installed on this water heater when connected

to copper pipe, see figure 10 also.

Figures 9 and 10 show the typical attachment of the water piping to

the water heater. The water heater is equipped with 3/4 inch NPT

water connections.

note: If using copper tubing, solder tubing to an adapter before

attaching the adapter to the water heater connections. do not

solder the water lines directly to the water heater connections.

It will harm the dip tube and damage the tank.

t & p valve and pipe Insulation (if supplied)

1. Locate the temperature and pressure relief valve on the water

heater (also known as a T&P relief valve). See Figure 11.

2. Locate the slit running the length of the T&P relief valve insulation.

3. Spread the slit open and fit the insulation over the T&P relief

valve. See Figure 11. Apply gentle pressure to the insulation

to ensure that it is fully seated on the T&P Relief Valve. Once

seated, secure the insulation with duct tape, electrical tape, or

equivalent. IMPORTANT: The insulation and tape must not block

the discharge opening or hinder access to the manual relief lever

(Figure 11). Ensure a discharge pipe is installed into the T&P

valve discharge opening per the instructions in this manual.

4. Locate the hot water (outlet) & cold water (inlet) pipes to the water heater.

5. Locate the slit running the length of a section of pipe insulation.

6. Spread the slit open and slip the insulation over the cold water

(inlet) pipe. Apply gentle pressure along the length of the insulation

to ensure that it is fully seated around the pipe. Also, ensure that the

base of the insulation is flush with the water heater. Once seated,

secure the insulation with duct tape, electrical tape, or equivalent.

7. Repeat steps 5 and 6 for the hot water (outlet) pipe.

8. Add additional sections of pipe insulation as needed.