Key benefits – Sandvik Coromant Quick Change for CNC Lathes User Manual

Page 6

6

1. Reduced batch change over time using tooling kits

Quicker tool changing

- External turning (5 to 10 mins)

this increases when using shank tools with high pressure

coolant.

- Internal turning (5 to 15 mins)

with boring bars it takes longer time than a shank tool with

center height and internal coolant setting.

- Driven tool holders (5 to 20 mins)

standard driven tools are either ER collets or face milling.

ER has a limited tool diameter allowing only end milling

(max dia 25 with ER40). This means either low productivity

or 2 separate driven units are needed which increases the

setting time and investment.

Key benefits

-

Quick change versus shank and conventional ER

driven units

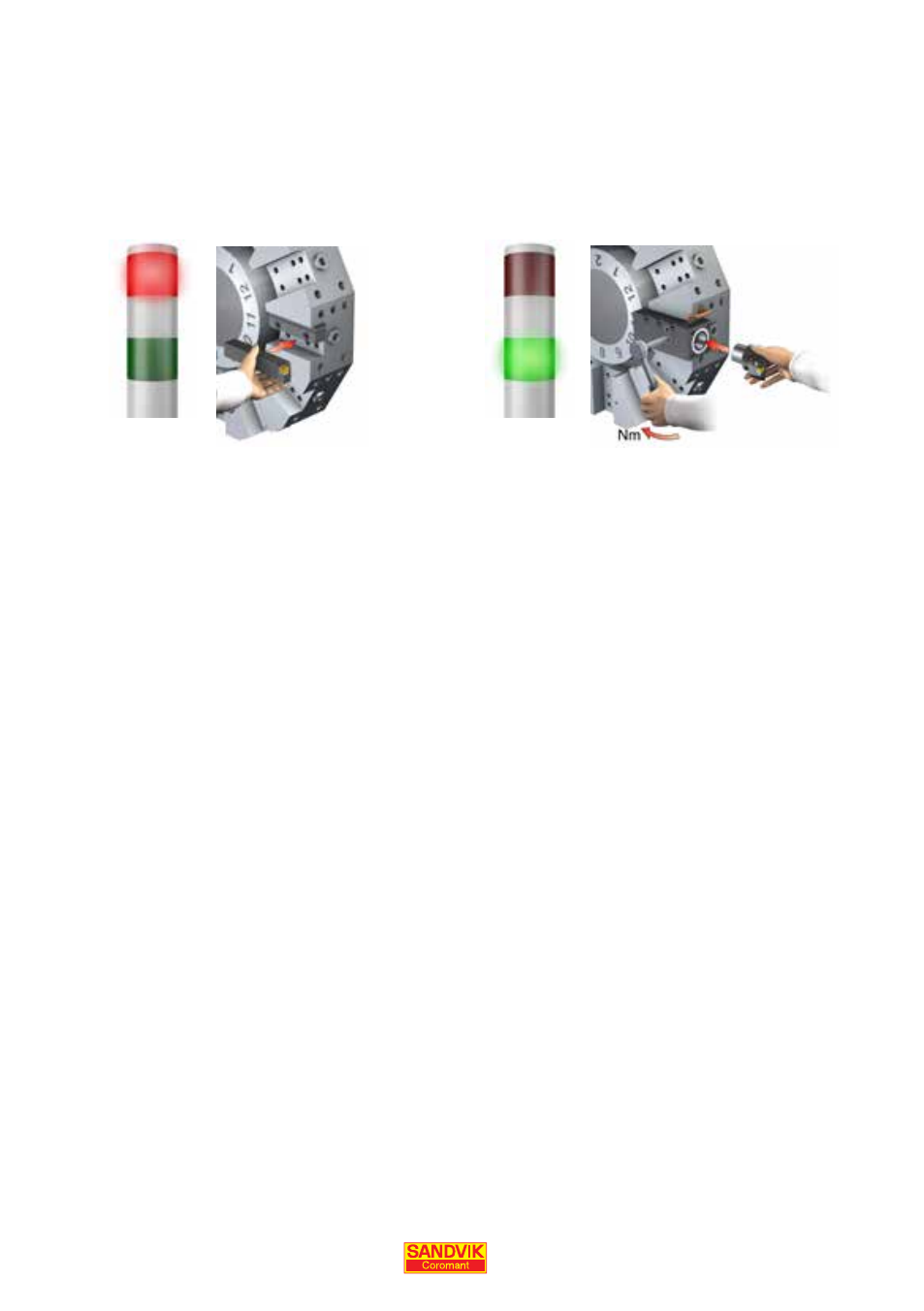

Increase machine utilization –

Green Light Machining

5-10 mins

30 secs