Periodic evaluation, Hour open-circuit test, Amp capacity test – Outback Power Systems EnergyCell RE Battery Owners Manual User Manual

Page 18: Maintenance, Table 2 troubleshooting

Maintenance

18

900-0127-01-00 Rev D

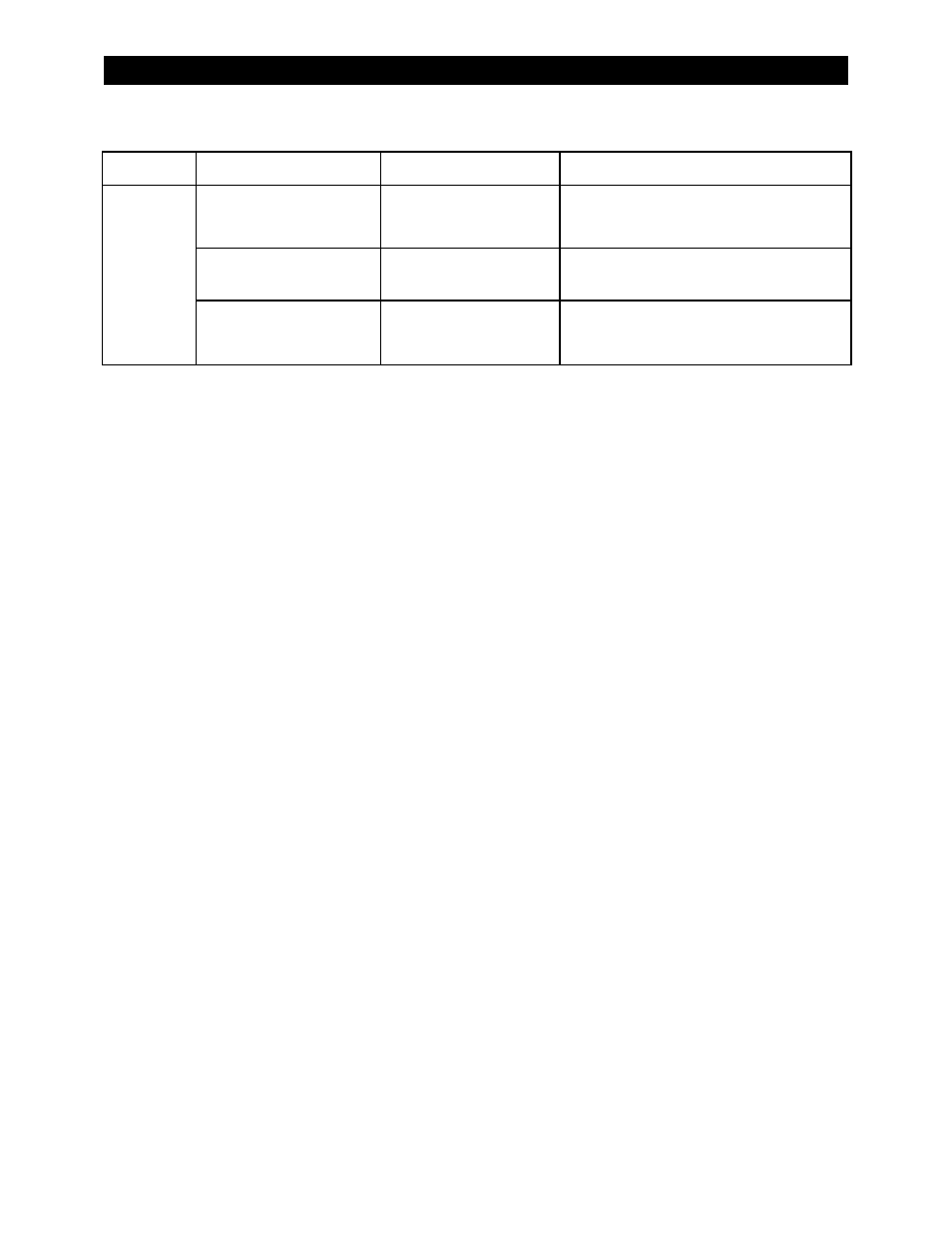

Table 2 Troubleshooting

Category

Symptom

Possible Cause

Remedy

Current

testing

Charging current to series

string is zero; failure to

support load

Open connection or open

battery cell in string

Check and clean all connections. If battery

appears to have an open cell, test and replace

as needed. Replace hardware as necessary.

Charging current to series

string remains high over time

Batteries require additional

time to charge

Normal behavior; no action necessary.

Charging current to series

string remains high with no

corresponding rise in voltage

Shorted cell

Test and replace battery as necessary.

A shorted cell may contribute to thermal

runaway.

Periodic Evaluation

Upon replacement of a battery (or string), all interconnect hardware should be replaced at the same time.

To keep track of performance and identify batteries that may be approaching the end of their life, perform the

following tests during on a quarterly basis following commissioning (see page 13). Tests must be made with a

high-quality digital meter. Voltages must be measured directly on battery terminals, not on other conductors.

All connections must be cleaned, re-tightened, and re-torqued before testing. If a battery fails any test, it may be

defective. If this occurs under the conditions of the warranty, the battery will be replaced according to the terms

of the warranty.

Bring the batteries to a full state of charge before performing either of the following tests.

24-Hour Open-Circuit Test

Remove all battery connections, then allow the battery to rest in this state for 24 hours. Test the battery voltage,

compensating for temperature. The EnergyCell RE battery should measure 12.84 Vdc. The EnergyCell GH

battery should measure 12.95 Vdc. A battery below 12.6 Vdc has lost capacity and may need to be replaced.

25-Amp Capacity Test

1. Install a DC load which draws a continuous 25 Adc. This allows the results to be correlated to the specified

capacity. The load may be used on either a single battery or a full string.

2. The load test unit wires must be sized correctly. For load testing all wiring should have a minimum ampacity

of 150% of the load current.

3. With this load, discharge the batteries until they have reached 10.5 Vdc per battery (1.75 Vdc per cell).

4. Monitor the elapsed time. At the same time, monitor the battery’s temperature.

5. Record the temperature at the end of the test. Use the equation below to adjust the results for temperature.

M

c

= M

r

(1 – 0.009 [T – 26.7])

where M

r

= actual elapsed minutes

T = temperature at end of run time

M

c

= minutes corrected for temperature with a baseline of 80°F (26.7°C).

6. Compare M

c

with the appropriate value in Table 1 on page 13. If the result is less than 80% of this number,

the battery (or string) may need to be replaced.