Dc wiring, Terminal hardware, Energycell batteries – Outback Power Systems EnergyCell RE Battery Owners Manual User Manual

Page 11

EnergyCell Batteries

900-0127-01-00 Rev D

11

DC Wiring

CAUTION: Equipment Damage

Never reverse the polarity of the battery cables. Always ensure correct polarity.

CAUTION: Fire Hazard

Always install a circuit breaker or overcurrent device on the DC positive

conductor for each device connected to the batteries.

CAUTION: Fire Hazard

Never install extra washers or hardware between the mounting surface and the

battery cable lug or interconnect. The decreased surface area can build up heat.

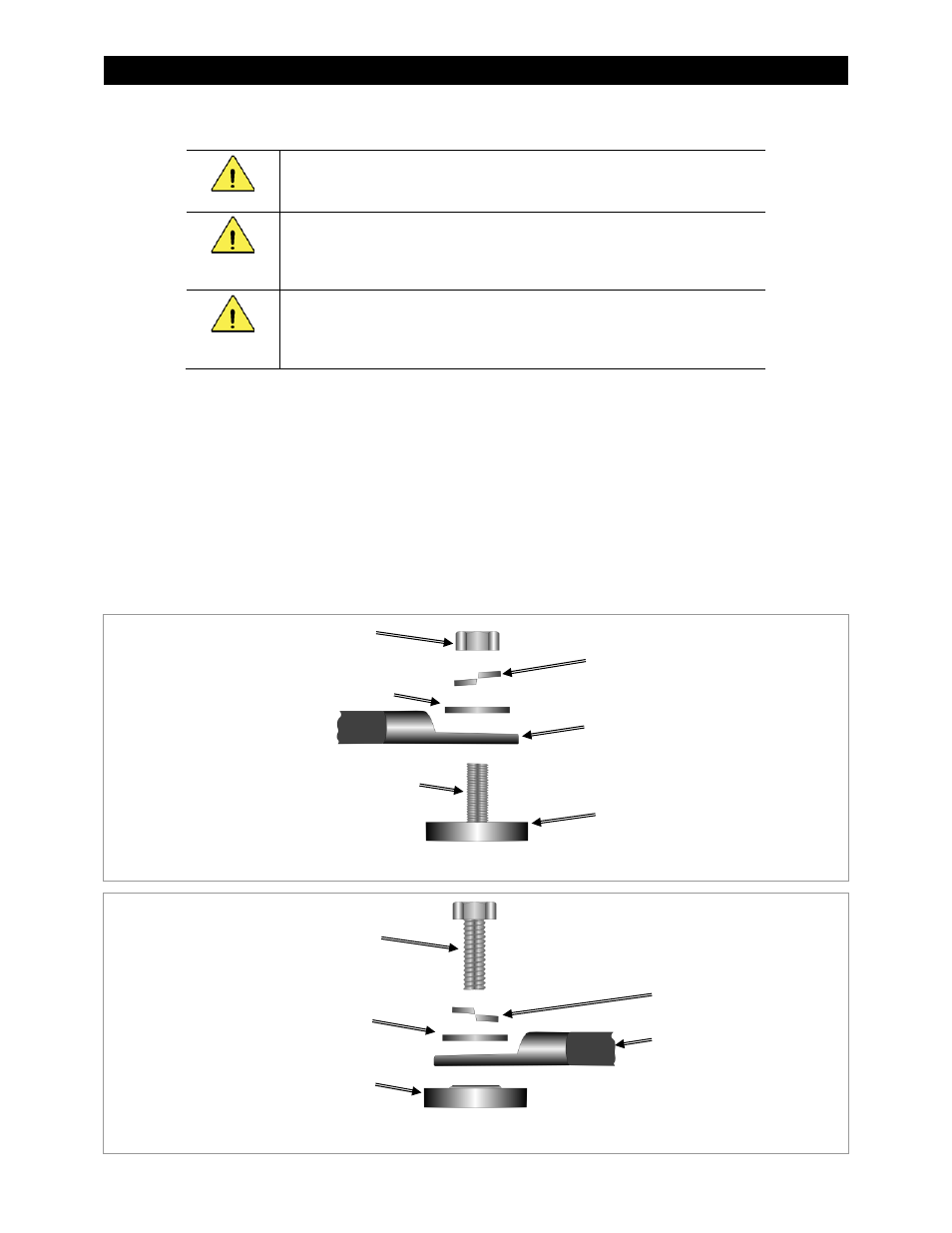

Terminal Hardware

EnergyCell batteries use one of two terminal types: A threaded stud which receives a nut, or a threaded hole

which receives a bolt. The terminal type, hardware sizes, and torque requirements may be different between

battery models. See Table 4 and Table 5 on page 19 for the requirements of a particular model. However, all

terminal hardware is assembled as shown in either Figure 9 or Figure 10.

NOTE: Install the cable lugs (or interconnects) and all other hardware in the order illustrated. The lug or

interconnect should be the first item installed. It should make solid contact with the mounting surface. Do not

install hardware in a different order than shown.

NOTE: To avoid corrosion, use plated lugs on cable terminations. When multiple cables are terminated, use

plated terminal bus bars.

Figure 9

Stud Terminal Assembly

Figure 10

Bolt Terminal Assembly

Lock Washer

Battery

Terminal

Surface

Battery Terminal Stud

Cable Lug or

Interconnect

Flat Washer

M6 Nut

Battery

Terminal

Surface

UNC Bolt

Lock Washer

Flat Washer

Cable Lug or

Interconnect