Yetter 6150 Series Markers User Manual

Page 7

7

SERVICE

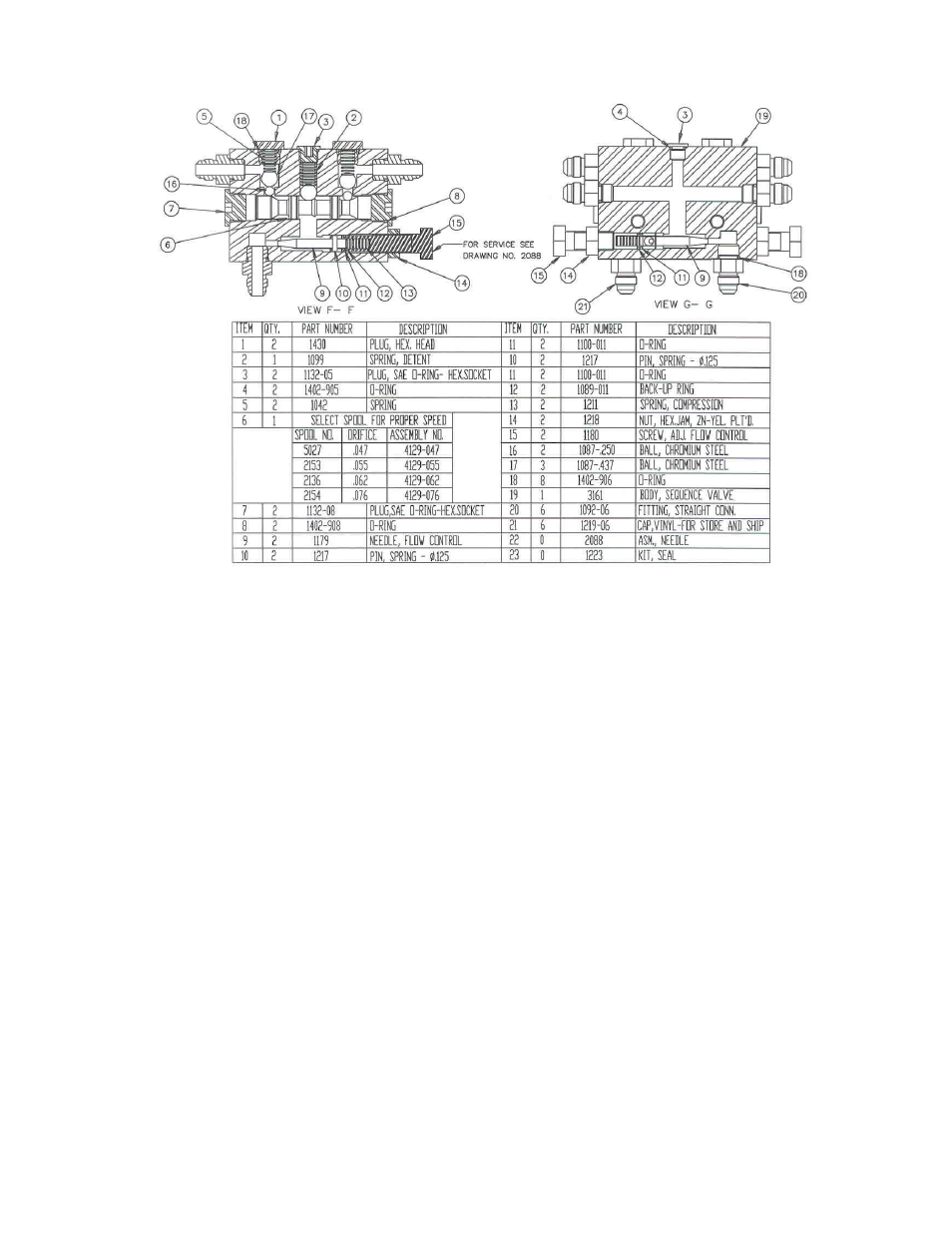

MARKER SEQUENCE VALVE

SERVICE REPAIR KIT – 2515-349

DISASSEMBLY and ASSEMBLY

If markers do not sequence, clean dirt from valve

spool bore (6). If markers tend to creep

downward, check for dirt, nicks/scratches in ball

check valve areas (16).

Note: Be sure the hoses are connected to the

correct ports before disassembling the valve for

cleaning or repair. (See schematics.)

Disassembly:

1. Remove hex head plugs (1), springs (2), and

steel balls (16 & 17).

2. Remove plug (3), spring (2), steel ball (17).

3. Remove plugs (7) from each end of body.

Important! Be sure plugs, springs and balls (Step

1 and 2) are removed before attempting to

remove spool.

4. Carefully remove spool (6) from valve body.

5. Remove flow restrictor assembly (15) from

valve body.

Inspection:

1. Clean spool and restrictors in solvent.

Note: Restrictor disassembly is not required

for cleaning.

2. Clean valve body after checking exterior for

signs of o-ring leakage.

3. If spool is nicked or scratched, remove with

crocus cloth. Spool must slide freely in bore.

1. If ball seats are nicked or scratched, install

larger ball against seat, tap ball with brass

rod to “seat” ball.

Note: Remove spool for this procedure.

2. Inspect o-rings. Replace if necessary.

Assembly:

1. Apply clean hydraulic fluid to threads, o-

rings, spool, valve bore. Reassemble in

reverse order of disassembly.

2. Open restrictors one turn minimum.

3. Install valve on planter and readjust marker

operating speed with restrictors.

Marker Operation

Markers fail to sequence

Raised marker slowly lowers

Valve spool stuck in sequence

valve

Check ball not seated in

Disassemble valve and clean

spool

Disassemble valve and re-

seat ball