Tuff Country 55900 - Toyota Tundra 99-04 4.5 kit User Manual

Page 11

55900NB1. Working on the driver side, secure the previous-

ly installed ball joint spacer and the knuckle support bracket

to the neck of the knuckle using the new 7/16” hardware. Get

the 7/16” hardware started but DO NOT tighten at this point.

Secure the driver side knuckle support bracket to the body of

the knuckle using the new 5/16” x 1 3/16” x 2” round u-bolts

and hardware but DO NOT tighten at this point. Secure the

3/8” x 1 1/2” bolt to the new knuckle support bracket but do

not tighten at this point. Move back to the new 7/16” x 1 1/2”

bolt and hardware and add some loctite and torque to 45 ft

lbs. Then tighten the 3/8” x 1 1/2” bolt until it makes contact

with the body of the knuckle. Once the new 3/8” x 1 1/2” bolt

makes contact with the knuckle, torque the U-bolts to 24 ft

lbs. Repeat procedure on passenger side.

65. Locate the driver side and passenger side sway bar drop

brackets. Also, locate (4) 3/8” x 1” bolt, (8) 5/16” USS flat

washers and (4) 3/8” unitorque nuts from hardware bag

55900NB1. Working on the driver side, secure the new driv-

er side sway bar drop bracket to the stock location and

secure using the new 3/8” x 1” bolt and hardware. Make sure

to use loctite and torque to 32 ft. lbs. Special note: once

the new sway bar drop bracket is installed, it will move

the sway bar down and towards the rear of the vehicle.

Repeat procedure the passenger side.

66. Locate the sway bar and the OE sway bar hardware.

Working on the driver side, install the sway bar to the newly

installed sway bar drop brackets and secure using the stock

hardware. Make sure to use loctite and torque to 18 ft lbs.

Repeat procedure on the passenger side.

67. Locate the sway bar end link hardware. Working on the

driver side, install the sway bar to the sway bar end link posi-

tion and secure using the stock hardware. Make sure to use

loctite and torque to 18 ft lbs. Repeat procedure on the pas-

senger side.

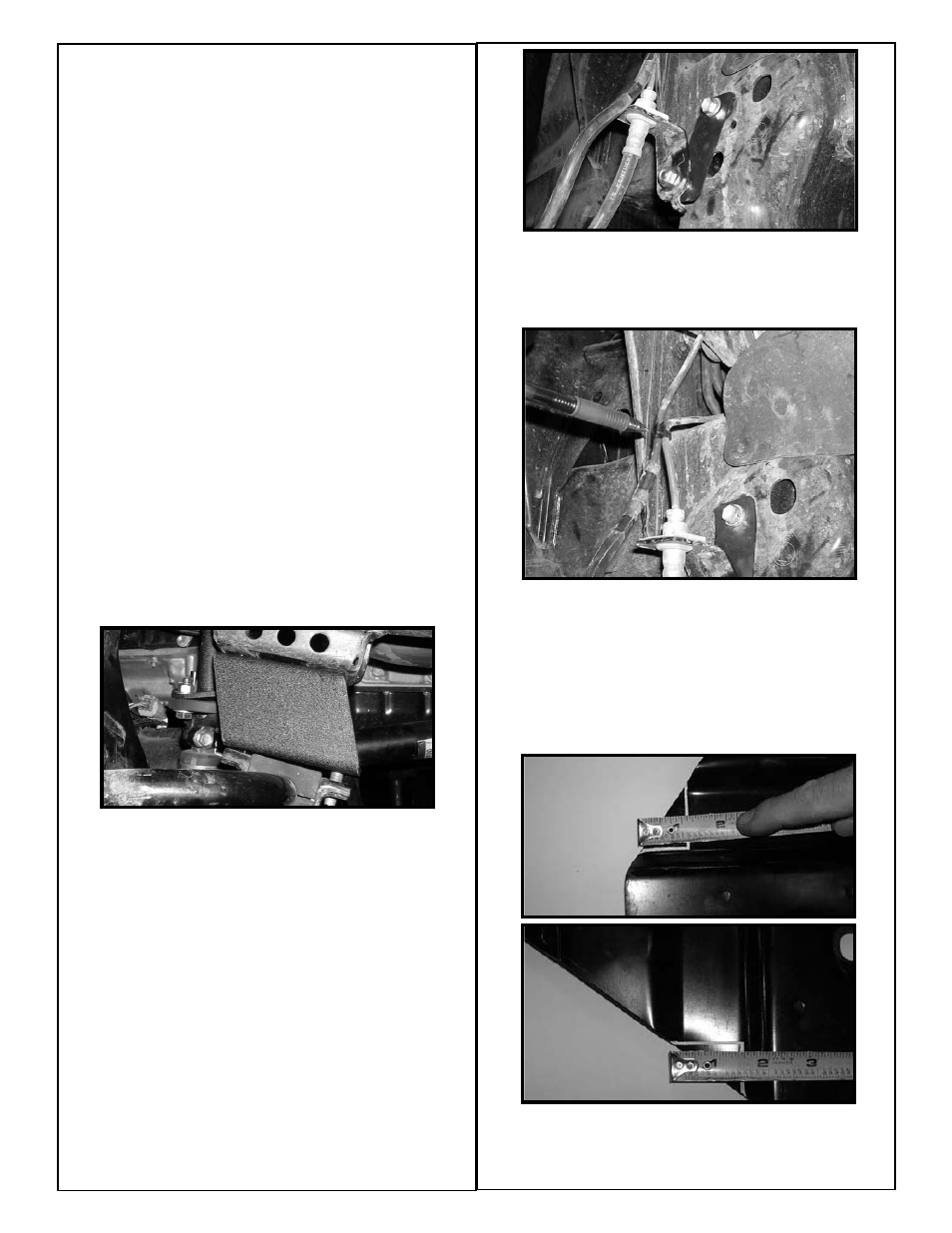

68. Locate (2) BLR01 front brake line relocation brackets

from hardware bag 55900NB2. Locate (2) 5/16” x 3/4” bolts,

(4) 1/4” USS flat washers and (2) 5/16” unitorque nuts from

hardware bag 55900NB1. Also, locate the stock brake line

bracket hardware. Working on the driver side, attach the new

brake line relocation bracket to the frame location and

secure using the stock hardware. Do not tighten at this

point. Now attach the stock brake line bracket to the newly

installed brake line relocation bracket using the new 5/16” x

3/4” bolt and hardware. Make sure to use loctite and torque

to 14 ft lbs. Add some loctite to the stock bolt holding the

new brake line relocation bracket to the frame location and

torque to 12 ft lbs. Repeat procedure on the passenger side.

69. Locate the (2) zip ties from hardware bag 55900NB2.

Working on the driver side, zip tie the stock brake line and

the stock ABS lines together. Cut off the excess part of the

zip tie. Repeat procedure on the passenger side.

70. Locate the stock skid plate. Place the skid plate flat on a

work bench. Working on the driver side of the skid plate,

measure from the leading edge of the skid plate towards the

back of the skid plate 1 1/4” and scribe a mark with white out

or a white marker. Now measure 1 1/2” from the leading

edge towards the inside of the vehicle and scribe a mark.

Repeat procedure on the passenger side of the skid plate.

With a suitable cutting tool, carefully notch out the skid plate

on the lines that were scribed earlier in this step.

71. Locate the stock skid plate hardware. Install the modified

skid plate into the OE location and secure using the hard-

ware. Make sure to use loctite and torque to 18 ft lbs.