Merit Medical Mentor Simulator/Tester User Manual

Page 4

2

•••••••••• SECTION I ••••••••••

VERIFYING THE CALIBRATION OF THE

MERITRANS TRANSDUCER

USING THE MENTOR

Some conventional transducers have calibration

ports located in their disposable cable or on the

backside of the transducer. This design allows

verification of calibration to be accomplished

without accessing the sterile fluid path. When

using a transducer of this design, the steps for

verification of calibration with the Mentor are

described in Section II.

As verification of calibration on the Meritrans

must be done by accessing the sterile fluid

path, a sterile, 0.2 micron bacteriological filter

(Catalog item #MER555) should be fitted

between the Mentor test system and the sterile

fluid path to avoid contamination of the

pressure monitoring system. See Diagram A

below.

WARNING:. Disconnect the patient from the

pressure monitoring system when verifying

calibration through the transducer’s fluid path.

PRECAUTION: Allow the transducer to

warm-up for one minute prior to taking

measurements.

1. Attach the sterile, bacteriological filter directly

to the transducer or to its stopcock to ensure

that the fluid path remains sterile. Do not

connect any tubing between filter and

transducer. See Diagram A below.

2. Prior to connecting the Mentor to the

transducer, turn the ON/OFF button to the ON

position to automatically zero the Mentor to

atmospheric pressure.

3. Connect the pressure monitoring tubing

(suggested for use with the Mentor - Catalog #

PM6012P) between the bacteriological filter and

the Mentor’s Transducer Test Port luer fitting.

4. Open the transducer to air. Zero the monitor

by using the “balance” or “zero” button on the

monitoring system’s control panel.

PRECAUTION: If the transducer signal does

not appear on the zero reference line after

using the monitor’s zero button, adjust the

position of the signal trace so that it is exactly on

top of the zero reference line by adjusting the

offset or signal position control knob of the

amplifier (as outlined in the monitoring

equipment’s Operator Manual).

5. For calibration, set a standard reference

display on the monitor screen. For example, a

common reference display is a 0 to 300 mmHg

scale with full deflection equaling 300 mmHg.

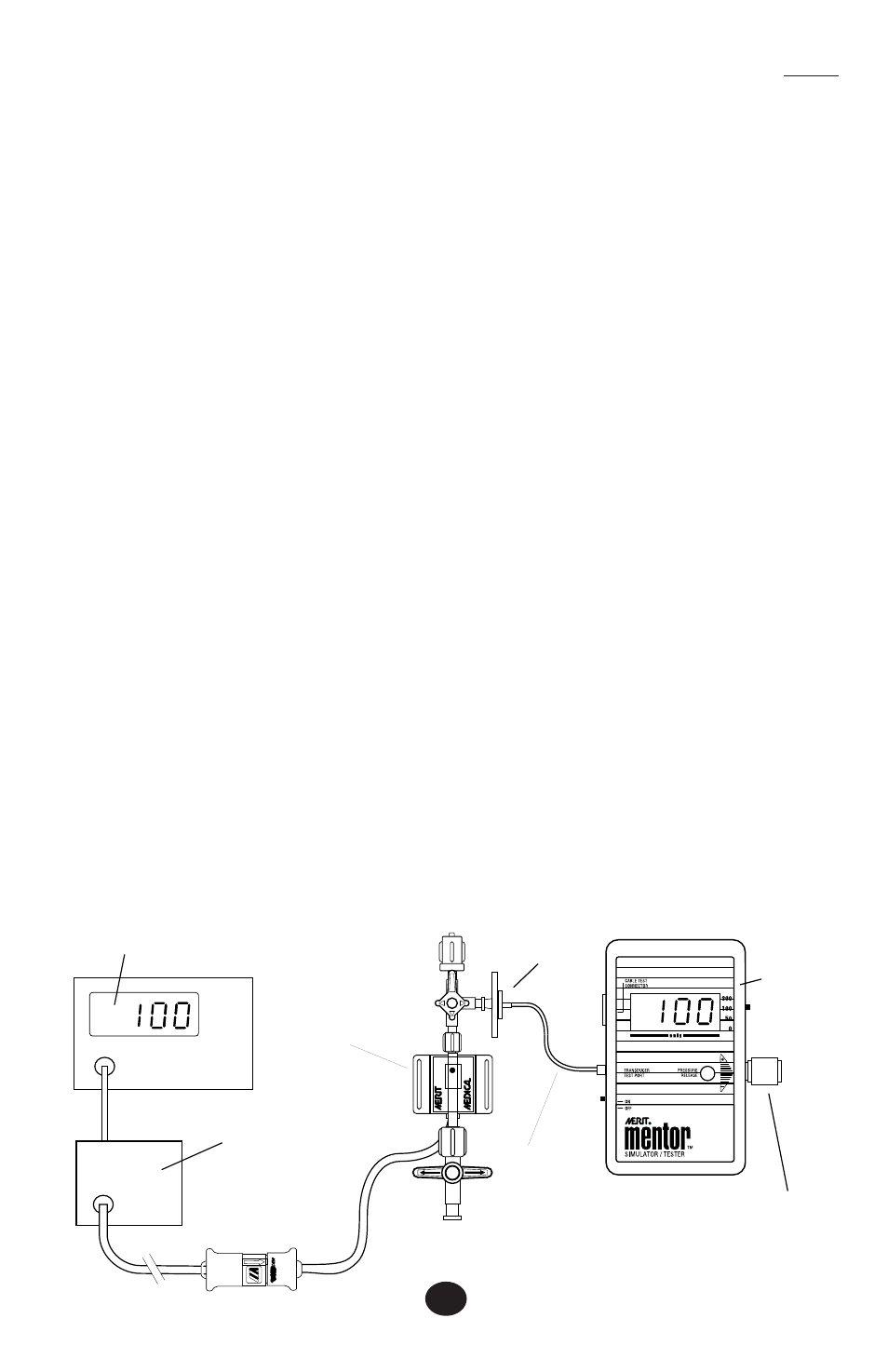

Diagram A: Fluid path verification of calibration

O

F

F

MONITOR

PRESSURE

REGULATOR KNOB

MONITOR

PRE-AMP

MENTOR

BACTERIOLOGICAL

FILTER

(Cat # MER555)

R

MERITRANS™

PRESSURE

MONITORING

TUBING

(Cat # PM6012P)