JELD-WEN JII040 Custom Clad Lift and Slide Door Systems User Manual

Page 6

ASSEMBLY AND INSTALLATION INSTRUCTIONS

for Custom Clad Lift and Slide Door Systems (JII040)

6

6

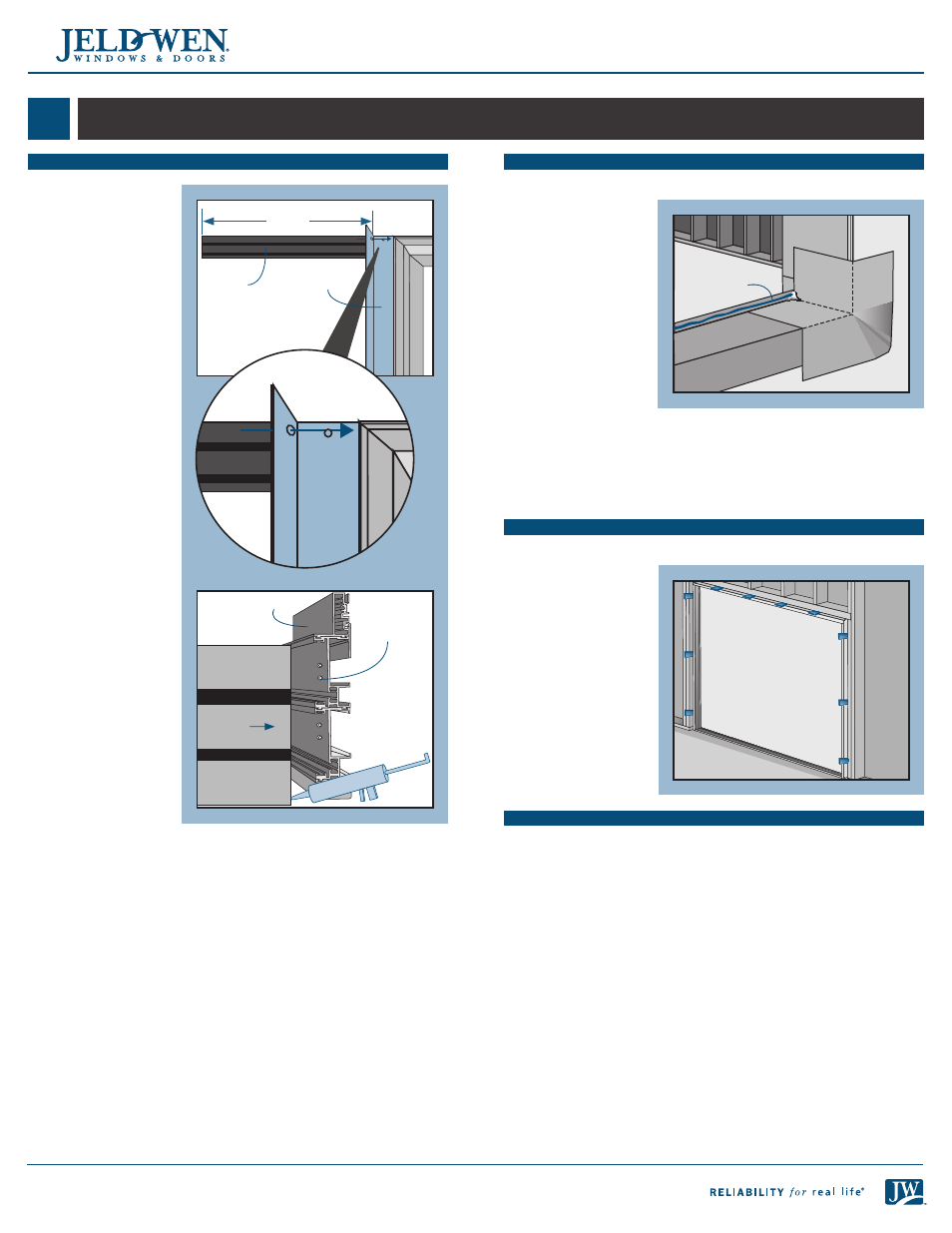

INSTALL DOOR

ASSEMBLE FRAME

1. On a clean and flat

surface, lay out

frame head, sill and

side jambs with

the exterior side

up. If installing a

pocketing system,

there will be post

interlock(s) for each

end that pockets

used instead of a

side jamb piece.

Post interlock(s) do

not install on the

extreme end of the

head and sill tracks,

but will install to

the side where

the pre drilled

holes are located

(approximately the

width of one panel

from the end of the

head and sill tracks).

2. If gaskets are

provided, adhere

to both ends of

the sill. Run a bead

of silicone on all

surfaces of the sill

as shown. Repeat

silicone application

for the head where

the ends will

contact the jambs.

3. Clamp the frame

corners as needed

to ensure that the

frame sections fit

together flush and

using the supplied 1

1/4" screws, fasten

the sill to the right and left jamb frame parts. The pre-drilled holes in

the jamb will line up with the screw bosses in the sill. Make sure the

attached gasket lies flat and the screws are inserted properly into the

screw bosses.

4. Using the supplied 1 1/4" screws, fasten the header to the right and

left jamb frame parts through the pre-drilled holes in the jambs.

5. Seal the screw heads and the outside of each corner joint with

sealant.

6"

6"

Interior

INSTALL FRAME

Warning!

To avoid injury, use at least two people to install.

1. If installing a pre-

formed sill pan,

follow manufacturer's

instructions and skip

this step. If installing a

job site fabricated sill

pan, run a continuous

3/8" bead of sealant

along the sill pan back

dam. When the frame

is installed, make

sure the frame makes

solid contact with the

sealant. Add more

sealant if necessary.

2. Tilt the frame into the rough opening. Adequately support the frame

until fully installed.

3. Align the exterior of the frame, or applied nailing fin, with the most

exterior surface of the structure (the exterior face of the concrete

wall, framing or sheathing).

SHIM THE JAMBS

Note!

Secure all shims with sealant.

1. From the interior,

shim the side jambs at

each pre-drilled hole.

Shim head track next

to pre-drilled holes.

Also shim at the strike

plate(s) if applicable so

that strike plate screws

(installed later) will

each penetrate a shim.

2. Inspect the frame for

square, level, and

plumb (remove and

reinstall if necessary).

FASTEN FRAME

1. To secure the head, fasten through each pre-drilled hole using #10 x 2

1/2" screws. Fastener holes should not go through, but next to shims.

Move shims accordingly to be next to fastener holes if necessary.

2. To secure the sill, put a generous amount of silicone sealant in each

pre-drilled hole and drive a #10 x 2 1/2" screw through each hole.

3. Secure the side jambs through each pre-drilled hole.

6. Verify the unit is square by re-measuring on the diagonals.

7. Verify the unit is plumb and level.

8. Use a level (4 foot recommended) to ensure there are no bows in the

framing.

9. Adjust screws and re-shim as needed to correct any bows.

Sealant

Sill

Jamb

Screw

holes

Post

interlock

Exterior side

shown

Frame

Depth of