Caution, A-26 / english, Hopper dust control filter – Nilfisk-ALTO Captor 4300 User Manual

Page 26: Engine oil – gasoline (petrol) & lpg, Engine oil - diesel

A-26 - FORM NO. 56041580 - Captor

™

4300, 4800, 5400 / CR 1100, 1200, 1400

A-26 / ENGLISH

HOPPER DUST CONTROL FILTER

The hopper dust control ¿ lter must be cleaned regularly to maintain the ef¿ ciency of the vacuum system. Follow the recommended ¿ lter

service intervals for the longest ¿ lter life.

CAUTION!

Wear safety glasses when cleaning the ¿ lter.

Do not puncture the paper ¿ lter.

Clean the ¿ lter in a well-ventilated area.

To remove the hopper dust control À lter...

1

Lift the Hopper Cover (18) on top of the hopper. Make sure that the Hopper Cover Prop Rod (12) is in place.

2

Inspect the top of the Hopper Dust Control Filter (19) for damage. A large amount of dust on top of the ¿ lter is usually caused by a hole

in the ¿ lter or a damaged ¿ lter gasket.

3

Turn the two hold-downs to the side (one on each side at the front of the frame) to release the shaker frame, then swing the Dust Filter

Shaker Assembly (20) up and latch in place with the Shaker Assembly Latch (21).

4

Lift the Hopper Dust Control Filter (19) out of the machine.

5 Clean

the

À lter using one of the methods below:

Method

“A”

Vacuum loose dust from the ¿ lter. Then gently tap the ¿ lter against a À at surface (with the dirty side down) to remove loose dust and

dirt. NOTE: Take care not to damage the metal lip which extends past the gasket.

Method

“B”

Vacuum loose dust from the ¿ lter. Then blow compressed air (maximum pressure 100 psi) into the clean side of the ¿ lter (in the opposite

direction of the airÀ ow).

Method

“C”

Vacuum loose dust from the ¿ lter. Then soak the ¿ lter in warm water for 15 minutes, and then rinse it under a gentle stream of water

(maximum pressure 40 psi). Let the ¿ lter dry completely before putting it back into the machine.

6

Follow the instructions in reverse order to install the ¿ lter. If the gasket on the ¿ lter is torn or missing, it must be replaced.

ENGINE OIL – GASOLINE (PETROL) & LPG

Check the engine oil level when the machine is parked on a level surface and the engine is cool. Change the engine oil after the ¿ rst 35 hours of operation

and every 150 hours after that. Use any SF or SG rated oil meeting API speci¿ cations and suited to seasonal temperatures. Refer to the Engine System

section for oil capacities and additional engine speci¿ cations. Replace the oil ¿ lter with every oil change.

TEMPERATURE RANGE

OIL WEIGHT

Above 60° F (15° C)

SAE 10W-30

Below 60° F (15° C)

SAE 5W-30

ENGINE OIL - DIESEL

Check the engine oil level when the machine is parked on a level surface and the engine is cool. Change the engine oil after the ¿ rst 35 hours of operation

and every 150 hours after that. Use CF, CF-4 or CG-4 oil meeting API speci¿ cations and suited temperatures (*important reference the oil/fuel type note

below for further diesel oil recommendations). Refer to the Engine System section for oil capacities and additional engine speci¿ cations. Replace the oil

¿ lter with every oil change.

TEMPERATURE RANGE

OIL WEIGHT

Above 77 °F (25 °C)

SAE 30 or 10W-30

32 °F to 77 °F (0 °C to 25 °C)

SAE 20 or 10W-30

Below 32 °F (0 °C)

SAE 10W or 10W-30

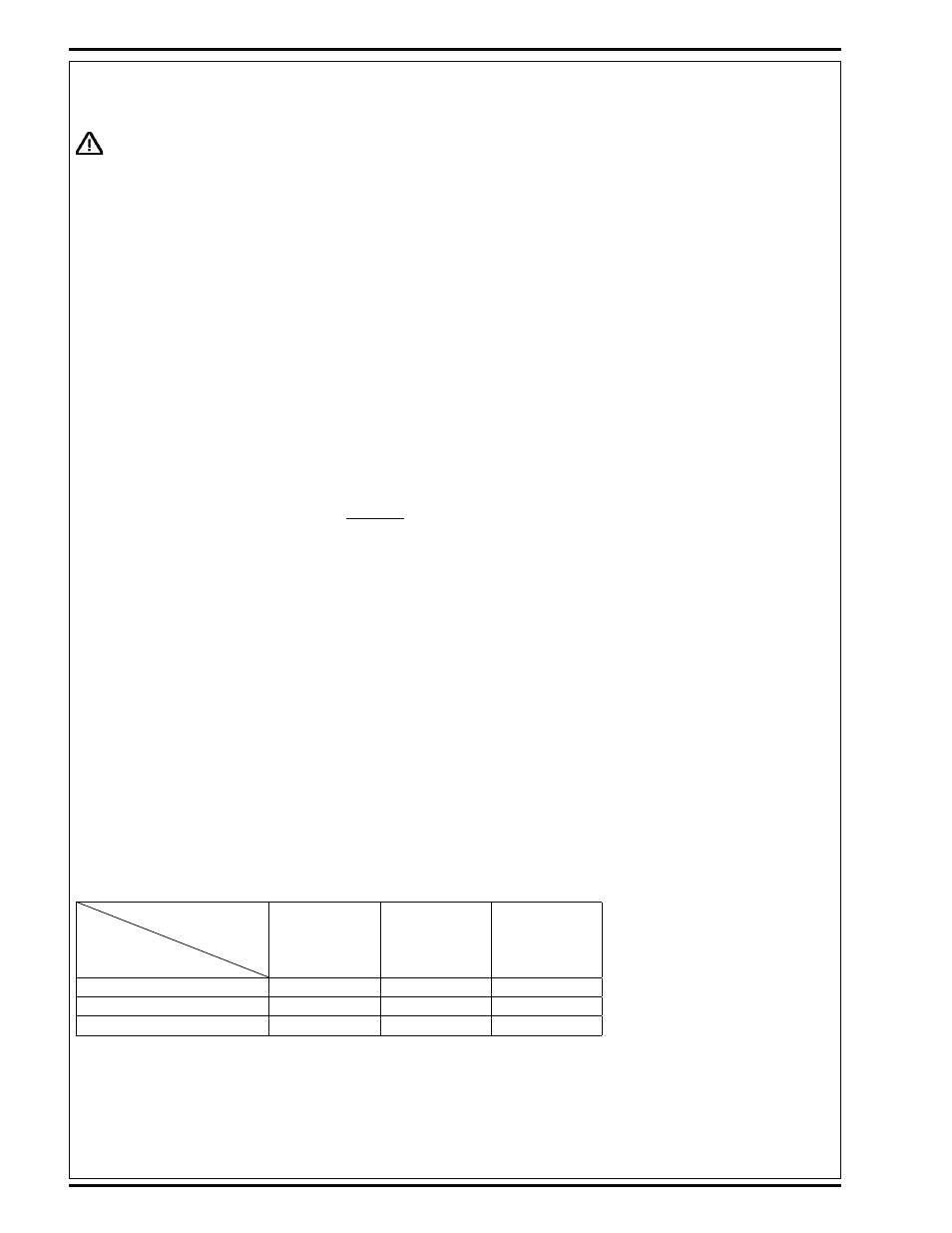

* Diesel Lubricating Oil Note:

With the emission control now in effect, the CF-4 and CG-4 lubricating oils have been developed for use of a low-sulfur fuel on-road vehicle engines.

When an off-road vehicle engine runs on a high-sulfur fuel, it is advisable to employ the CF, CD or CE lubricating oil with a high total base number. If

the CF-4 or CG-4 lubricating oil is used with a high-sulfur fuel, change the lubricating oil at shorter intervals.

• Lubricating oil recommended when a low-sulfur or high-sulfur fuel is employed.

Fuel

Lubricating

Oil class

Low sulfur

(0.5 % )

High sulfur

Remarks

CF

O

O

TBN 10

CF-4

O

X

CG-4

O

X

O : Recommendable

X : Not recommendable

revised 3/08