3 typical features and components – Sterlco GH-M Series Extrusion Control Weigh Hoppers User Manual

Page 15

Chapter 2: Functional Description

15 of 60

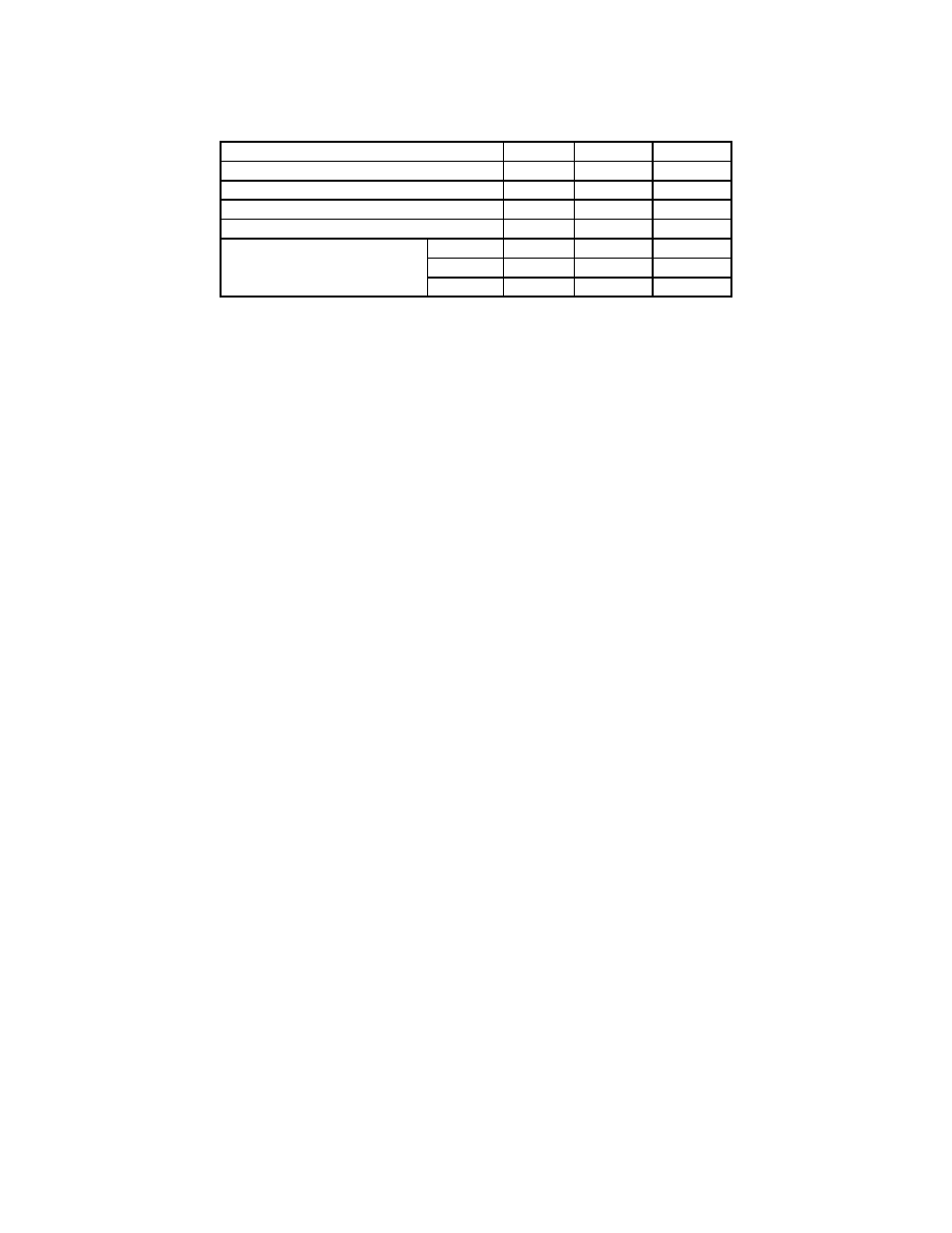

Figure 2: Equipment Specifications

10

20

40

600 (272)

1200 (680)

2500 (1134)

0.35 (10)

0.7 (20)

1.41 (40)

10

20

40

1 @ 10 kg

1 @ 20 kg

1 @ 30 kg

Height (5)

34.5 (875)

51.5 (1308)

56.5 (1435)

Width (5)

26.0 (650)

37.5 (952)

37.0 (940)

Depth (5)

22.0 (560)

37.0 (940)

40.0 (1016)

Model

Maximum Extrusion Rate, lbs/hr (kg/hr)

Approximate Dimensions, in. (mm)

Weigh Hopper Capacity, cu.ft. (Liters)

Typical W eigh Hopper Size, lbs.

Load Cell Capacity, kgs

2-3 Typical

Features and Components

Mechanical Features

• Removable stainless steel weigh hoppers.

• Stainless steel surge (supper supply) hopper with integral air cylinder and urethane

dump cone.

• Precision 1/10% span accurate cantilever load cell weighing system

• Inductive extruder tracking proximity switch (not necessary if writing extruder speed

through communications)

• Rugged industrial mild steel painted frame.

• Cast aluminum spool with drain and purge ports.

Figure 4: Typical GH Allen-Bradley PLC Enclosure

Controller Features

• LCD touch-screen interface display operator control panel with 8’ cable (optional on

GH-M units, system requires 1 per facility for setup and maintenance)

• Allen Bradley Micrologix 1500 PLC

• Thermocouple Input card for loadcell

• Analog Output module for GH Full Control units and GH-F Gravimetric Feeder

Systems.

• Manual key switch control function for reload

• Visual Alarm

• Alarm log

• Full control diagnostics

• Serial printer Output