Sterlco SGBD Series Batch Gravimetric Blenders User Manual

Page 49

BLN1-600A

Chapter 3: Installation

49 of 116

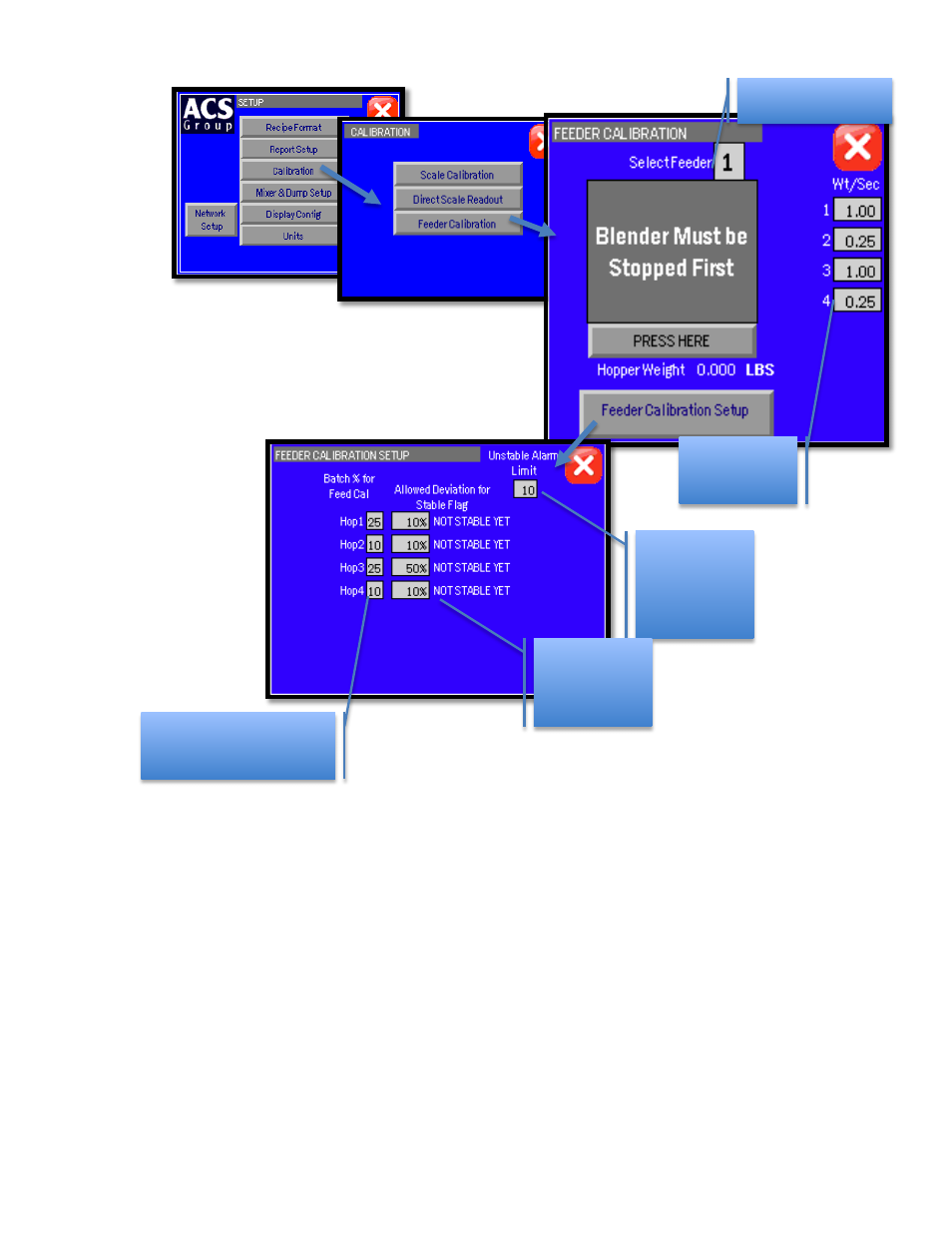

Feeder Calibration (AF & RAM Components)

Feeder calibration should be done on all Auger components prior to start-up. This allows the

blender to configure the parameters which will best suit the auger size and gearbox ratio of

the feeder. To perform a feeder calibration, the operator must enter the “Feeder

Calibration” screen (see menu structure), select a feeder number, then touch “Press Here.”

The feeder calibration will start automatically and will notify the operator when complete. If

the operator so desires, they can repeat the process by entering in a new feeder number and

touching the “Press Here” button.

If the blender does not see enough weight gain during the calibration process or if the weigh

hopper reaches maximum weight, then an error is given and the calibration is a failure.

Another useful feature on the “Feeder Calibration” screen is the ability to manually enter in

the “weight per second” values. This increases the blender learning process and the values

can be recorded for future blending.

Alarm Setup

This screen allows the operator to configure the alarm settings for each individual feeder. It

Follow Instructions

Pick a Hopper and

Follow instructions

Stored Feed

Calibration

values

Number of

batches to allow

blender to

stabilize before

alarm

% deviation of

last 3 measured

feeder

calibrations

% of batch size for target

weight during manual

feeder calibration