6 replacing the process heater – Sterlco MDB Series Dryers User Manual

Page 55

9. Re-install the rear and side shrouds. Re-connect the compressed air supply and electrical

power.

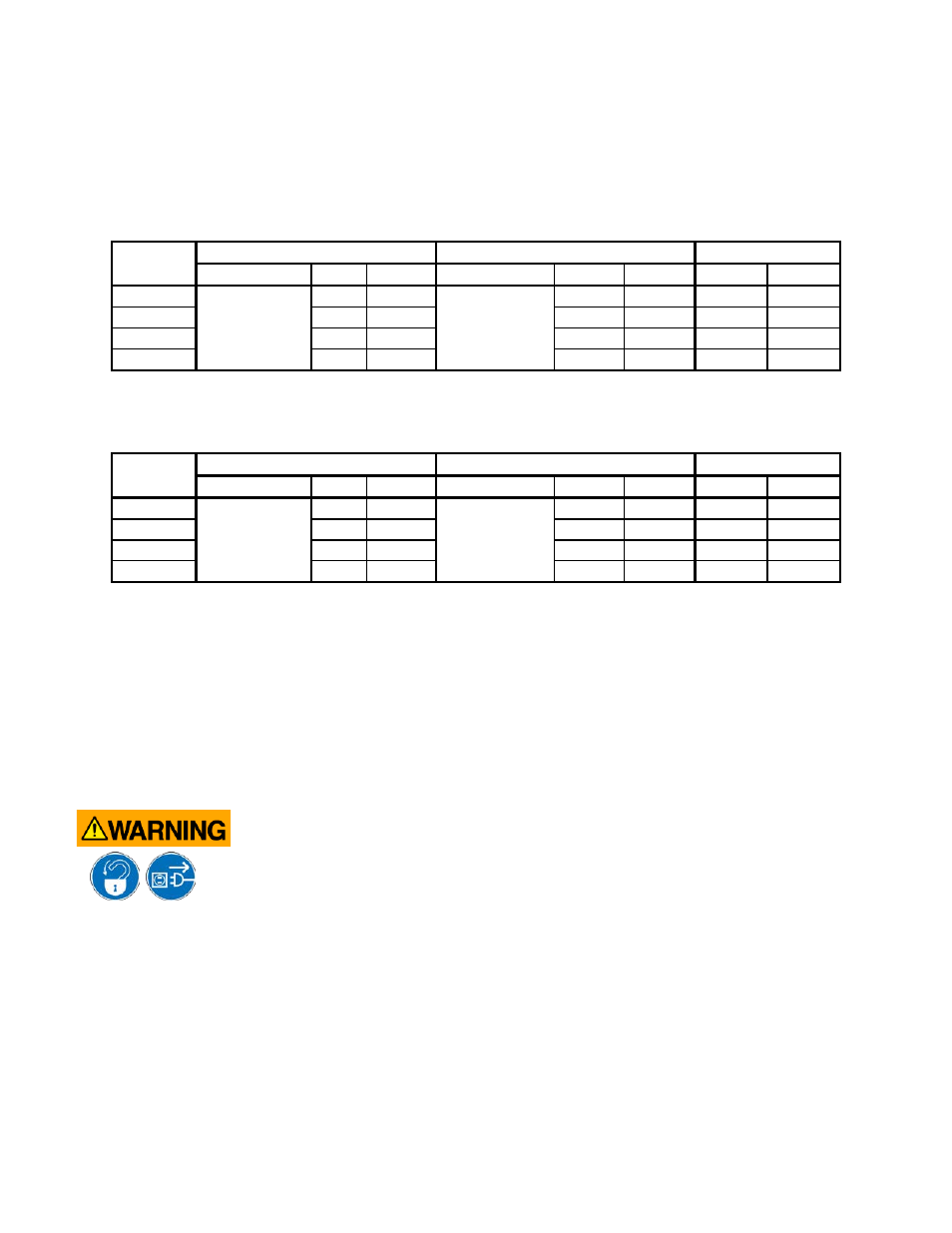

Figure 7:

Required Desiccant Amounts per Bed; Type 4X Desiccant (2 beds per unit)

Dryer

Large bead (Type 4X)

Small bead (Type 4X)

Total per bed

CFM

Part no.

lbs.

Kg

Part no.

lbs.

Kg

lbs.

Kg

50

W00000892

1.5

0.68

W00000893

10.5

4.75

12

5.44

100

3.0

1.362

21.0

9.534

24.0

10.896

150

9.0

4.086

30.0

13.620

39.0

17.706

225

9.0

4.086

30.0

13.620

39.0

17.706

Type 13X Desiccant

Dryer

Large bead (Type 13X)

Small bead (Type 13X)

Total per bed

CFM

Part no.

lbs.

Kg

Part no.

lbs.

Kg

lbs.

Kg

50

W00018050

1.5

0.68

W00018051

10.5

4.75

12

5.44

100

3.0

1.362

21.0

9.534

24.0

10.896

150

9.0

4.086

30.0

13.620

39.0

17.706

225

9.0

4.086

30.0

13.620

39.0

17.706

6-6 Replacing the Process Heater

Our dehumidifying dryers use Calrod-type heater elements mounted in a heater tube located in the

top rear of the cabinet. The wattage of the heater varies with model, voltage, temperature range,

etc., but the replacement procedure is the same.

If the process heater is mounted to the hopper, contact the manufacturer for the appropriate

replacement procedure.

Disconnect and lock out power before you replace heater elements!

Use the following procedure to replace the process heater:

1. Remove the bolts securing the process heater access cover.

2. Sketch the heater wiring configuration so you can properly re-wire the heater.

3. Remove the wires to the heater plate assembly being removed or replaced.

4. Remove the bolts securing the heater plate assembly, and slide out the assembly.

5. Remove the heater from the mounting plate by removing the large brass nuts and

washers.

Operation

55