6 drying hopper, Removing the rust inhibitor, Air trap considerations – Sterlco MDB Series Dryers User Manual

Page 25: 7 positioning your dryer

3-6

Drying Hopper

Removing the Rust Inhibitor

Rust preventative has been applied to internal unfinished surfaces. Remove rust inhibitor before

using the drying hopper.

Using a non-water based degreasing agent, clean all inside surfaces of the drying hopper. Allow

components to dry thoroughly.

Inspect the inside of the drying hopper for loose connections, foreign objects, or a blocked

diffuser.

Air Trap Considerations

The air trap assembly in the top of the drying hopper prevents ambient air from contaminating the

material being dried.

Keep the material level at the mid point of the air trap for maximum efficiency.

Use a hopper loader or vacuum conveying system to maintain the proper material level.

3-7

Positioning Your Dryer

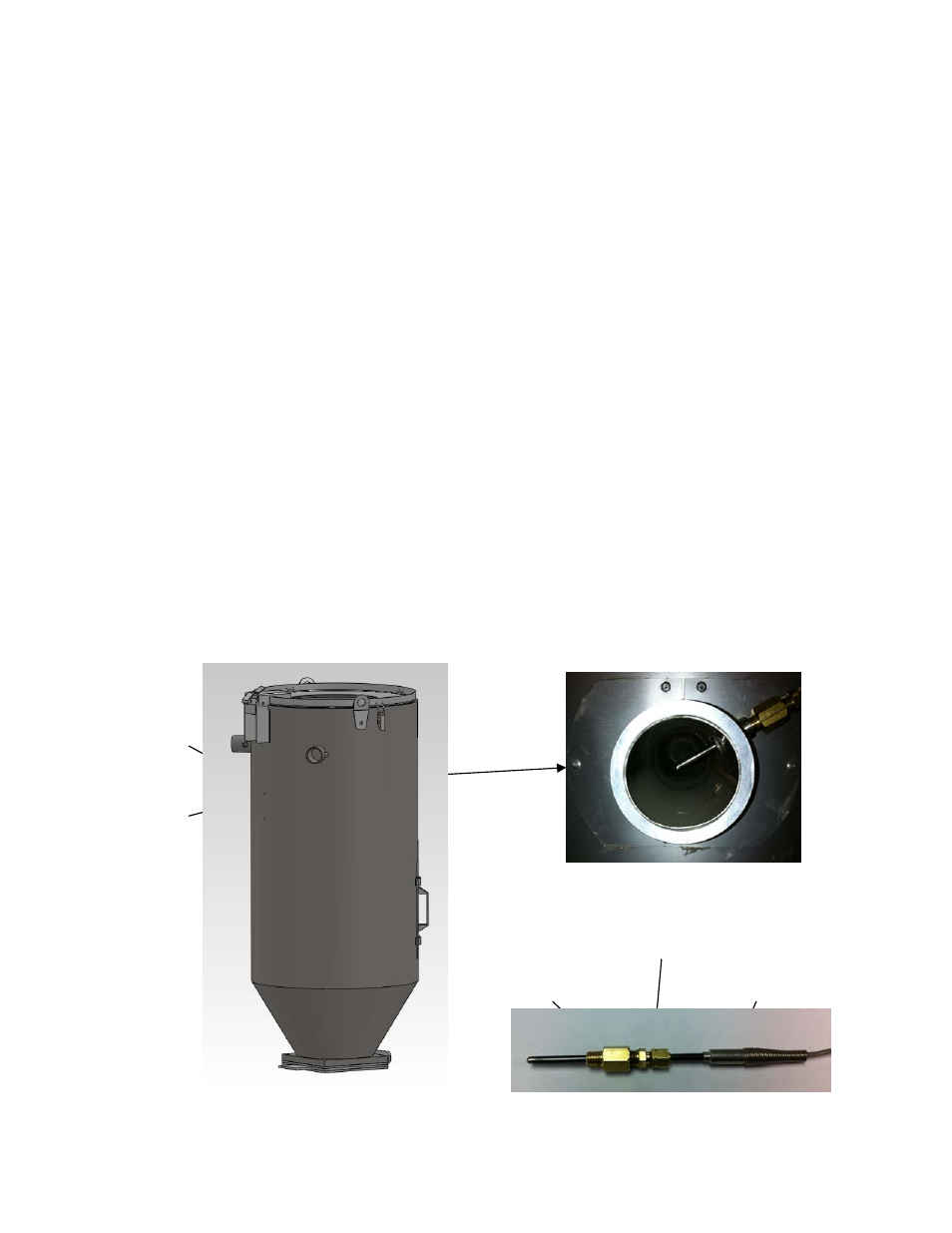

For the dryer work function properly it is critical to place the process air thermocouples on the

drying hopper inlet and outlet. These devices accurately monitor the air temperature entering and

leaving the drying hopper, the value of which is used by the control to maintain the process

temperature set point. Compression fittings are required to hold the thermocouple in place so that

the tip is approximately in the center of the tube as shown.

Air Inlet

Air Return

This photo demonstrates the proper

location of the thermocouple inside

the air inlet and return tubes.

Adapter (if required)

1/8” NPT to BSPT

1/8”

Compression fitting

Thermocouple

The locations of

the inlet and

return will vary

on different

drying hoppers.

Installation

25