1 requirements for configuring the hygromet mp, 2 function overview, Requirements for configuring the hygromet mp – ROTRONIC MP400H User Manual

Page 7: Function overview, E-m-hm-v1_10

E-M-HM-V1_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroMet MP Humidity Temperature

Meteorological Probe: User Guide

Instruction Manual

Document Type

Page 7 of 19

Document title

© 2009; Rotronic AG E-M-HM-V1_10

4.1 Requirements for configuring the HygroMet MP

Configuration of the HygroMet MP by the user and access to its functions requires the following:

o

PC with the ROTRONIC HW4 software (version 2.3.0 or higher) installed.

o

Service cable AC3006 to connect the HygroMet internal service connector to a USB port of the PC.

o

DC voltage source to power the HygroMet MP

Note: The RS-485 interface of the HygroMet MP 3-wire version can be used as an alternative to the service

connector to configure the HygroMet MP after connecting the HygroMet MP to a RS-485 network monitored

by a PC with the HW4 software.

4.2 Function overview

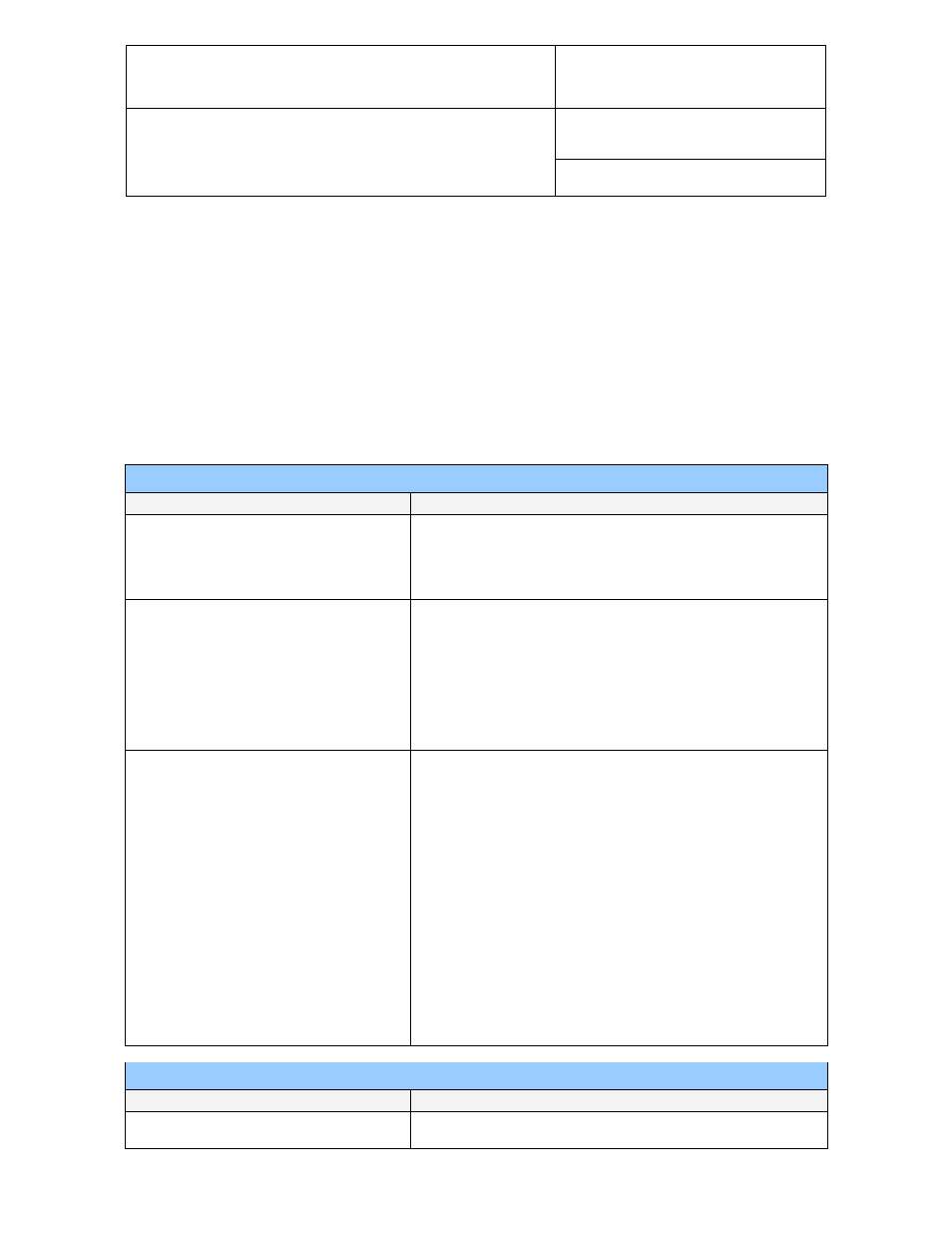

MEASUREMENT ACCURACY AND RELIABILITY (PROBE FUNCTIONS)

AirChip 3000 Functions

Description

► Humidity / temperature adjustment

o

1-point or multi-point humidity calibration or adjustment

o

1-point or 2-point temperature calibration or adjustment

o

Generate a time stamp for calibrations and adjustments

o

Retain and view last adjustment date and adjustment values

o

Generate calibration and adjustment protocols

► Automatic humidity sensor test

and optional drift compensation

Tests the humidity sensor for drift caused by contaminants and

can be used to automatically apply a correction. The test is

automatically carried out at regular intervals of time. Can be

configured, enabled, or disabled. The humidity sensor status

can be verified either with the HW4 software or with the

instrument display (if available) and is shown as Good, SQ-

tuned (corrected for drift) or Bad (defective)

► Data recording

The data recording function differs from a true data logging

function in the sense that the AirChip 3000 does not time stamp

the data. The data recording function can be use to investigate

events such as a sensor malfunction as well as to retrieve data

that would otherwise be lost

o

Start or stop data recording - up to 2000 value pairs (%RH

and temperature). Starting a recording session erases all

previously recorded data

o

The recording mode and log interval can be specified

o

When the device is powered off, the recording session is

paused but not ended As long as the recording session has

not been ended, the device automatically resumes recording

data when powered up again

o

The recorded data can be downloaded to a PC with the

HW4 software, time stamped and viewed

MEASUREMENT LOOP VALIDATION

Functions

Description

► Simulator mode

Used to make the HygroMet generate fixed values for the

humidity, temperature and calculated parameter. Can be