Dwyer WE04 User Manual

Page 8

Note: To speed up installation of the control wires to the ACT-MDXX modulating

actuator, it is recommended to remove the control module from the actuator. The

control module can be removed by removing the two mounting screws on the left

and right of the control module. Install the control wires to the correct terminal points

and then reinstall the control module.

Electric Actuator Maintenance

Once the actuator has been properly installed, it requires no maintenance. The gear

train has been lubricated and in most cases will never be opened.

Duty Cycle Definition

“Duty Cycle” means the starting frequency.

Fomula: Running Time (Running Time Rest Time) x 100% = duty cycle

Rest Time = Running Time x (1 - duty cycle) duty cycle

For example: The running time is 15 seconds

30% duty cycle 15 x [(1 - 30%) / 30%] = 35 The rest time will be 35 seconds

75% duty cycle 15 x [(1 - 75%) / 75%] = 5 The rest time will be 5 seconds

If the duty cycle is higher, the rest time will be shortened. It means the starting

frequency will be higher.

Thermal Overload

All actuators are equipped with thermal overload protection to guard the motor

against damage due to overheating.

Mechanical Overload

All actuators are designed to withstand stall conditions. It is not recommended to

subject the unit to repeated stall conditions.

Explosion-Proof Electric Actuators

1. DO NOT under any circumstances remove the cover of the

actuator while in a hazardous location. Removal of the cover

while in a hazardous location could cause ignition of hazardous atmospheres.

2. DO NOT under any circumstances use an explosion-proof electric actuator in a

hazardous location that does not meet the specifications for which the actuator was

designed.

3. Always verify that all electrical circuits are de-energized before opening the

actuator.

4. Always mount and cycle test the actuator on the valve in a non-hazardous

location.

5. When removing the cover, care must be taken not to scratch, scar of deform the

flame path of the cover and base of the actuator, since this will negate the NEMA

rating of the enclosure.

6. When replacing the cover, take care that the gasket is in place to assure proper

clearance after the cover is secured.

7. All electrical connections must be in accordance with the specifications for which

the unit is being used.

8. Should the unit ever require maintenance, remove from the hazardous location

before attempting to work on the unit.

If the actuator is in a critical application, it is advisable to have a standby unit in stock.

WARNING

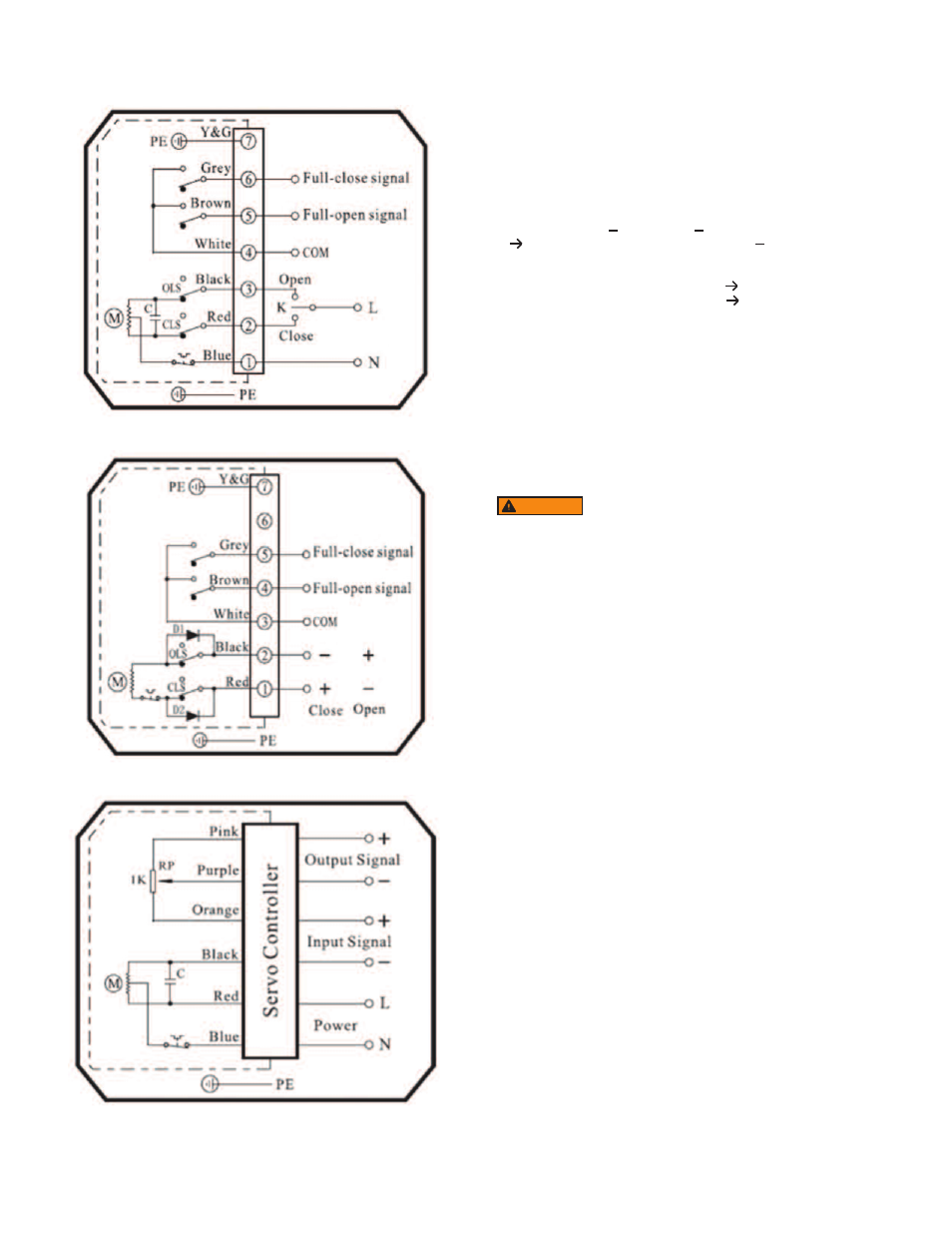

Wiring Diagrams for

TD01-TD06: 24 VDC

Wiring Diagrams for

TD01-TD09: 120 VAC, TD01-TD09: 220 VAC, TD01-TD09: 24 VAC

Wiring Diagrams for

MD01-MD09: 120 VAC, MD01-MD09: 220 VAC, MD01-MD09: 24 VAC

Electric Actuators Wiring Diagram: ACT-TD & ACT-MD

•

•

•

•

•

•

Page 8