Dwyer 265ER User Manual

Page 2

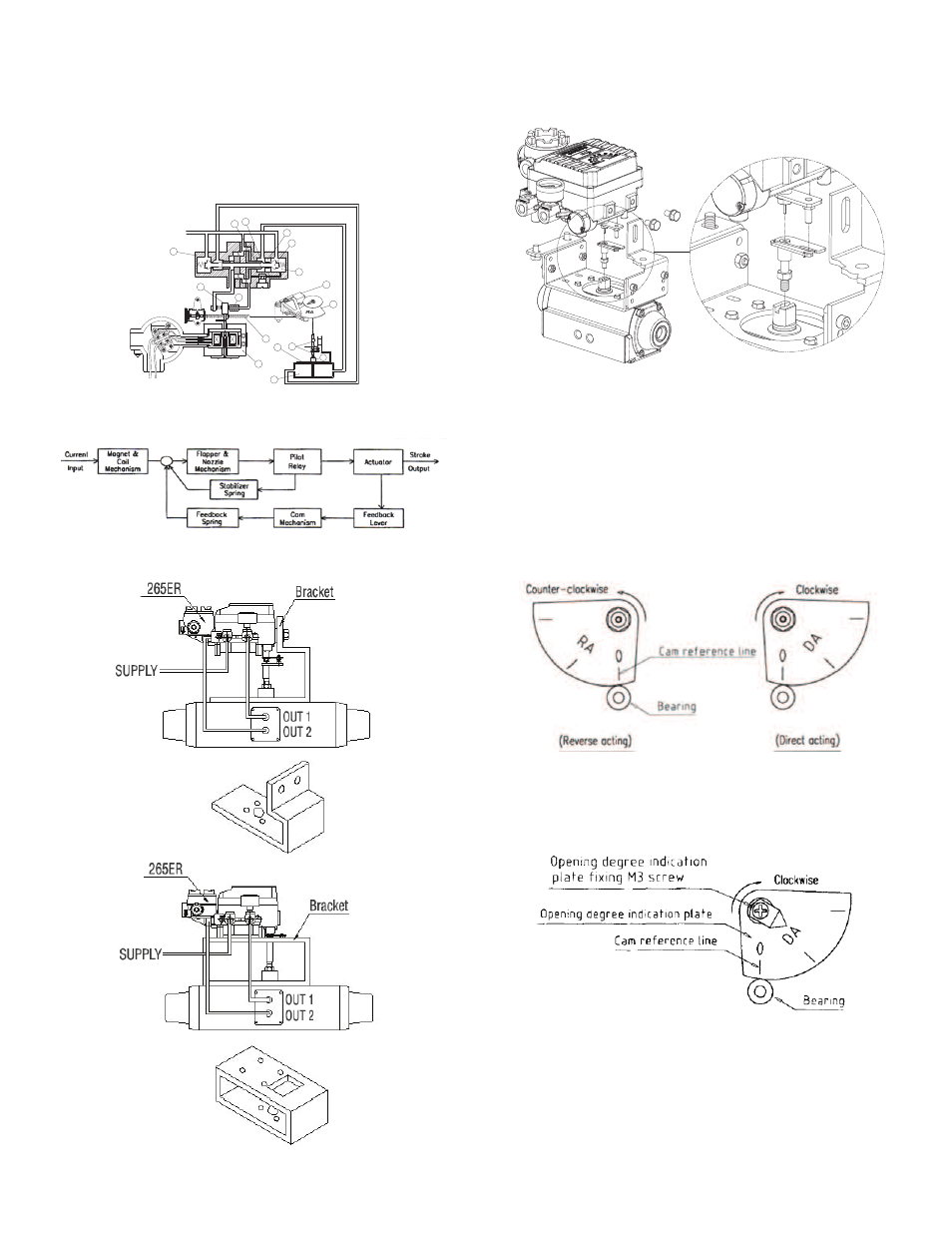

PRINCIPLE OF OPERATION

Increase the input current signal to change in lift position of valve. Force exerted

by (1) Torque Motor reduces Nozzle Back Pressure with increase in gap between

(2) Flapper and (3) Nozzle. Then (5) Spool moves upward and the (7) Seat opens

simultaneously. Air pressure of OUT1 pipe is discharged to (10) Actuator. As

pressure in the actuator chamber goes up, (12) Actuator Stem starts to rotate.

The movement of (12) Actuator Stem exerted force to the (a) Feedback Spring

through Feedback Shaft connections. Then (10) Actuator will stop at the point of

force balance exerted by the input current signal and the feedback spring.

BLOCK DIAGRAM OF 265ER

INSTALLATION

Example of attaching to actuator

Connection with Feedback Shaft

Attach to the position at which the positioner feedback shaft and the rotary

actuator main shaft are almost concentric (range in which the spring pin of

feedback shaft edge enters the hole of fork lever assembly shaft edge).

INSTALLATION cont.

Cam Attaching Procedure

Use the DA face of cam to turn the actuator main shaft clockwise (viewed from

the positioner front cover side) at the time of input feedback shaft. Use the RA

face to turn it counter-clockwise (reverse action). Correctly attach the cam to the

flange part of feedback shaft. Attach the cam in the procedure of loosening the

hexagonal nut with flange first, setting the using actuator to the starting position

and then setting the cam reference line and the bearing contact point of span

adjusting arm unit to the matching position. Do not apply the supply pressure

when attaching the cam as other wise it is very dangerous. When the positioner

is shipped out of our plant, the cam is tentatively tightened to the shaft. Be sure

to firmly lock the cam to the lock nut [tightening torque 17.7 to 22.1 in-lbs (2.0 to

2.5 Nm)].

Attaching Procedure of Opening Degree Indication Plate

Lock the cam and then adjust the zero point and span. Then fix the opening

degree indication plate to the shaft using the M3 screw provided. At the time, set

the opening degree indication plate to the state of attaching reference line.

SPA

RE

INPUT SIGNAL

4~20 mA

OUT2 OUT1

SUPPLY

OUT2

OUT1

OUT2

OUT1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

15

E