Dwyer 2800 User Manual

Page 3

Reverse Acting Calibration

When calibrated to operate in the reverse acting mode the minimum

input signal produces the maximum output pressure and increasing the

input signal results in decreasing the output pressure. Setting the unit to

operate in the reverse acting mode is accomplished by positioning

internal electrical switches.

Disconnect input signal and supply pressure. Take off the top cover by

removing the four screws.

Position switches as illustrated in figure 4. Replace cover. Set the input

signal to the minimum value being used. Turn the zero screw to set the

maximum output pressure. Set the span by applying the maximum input

signal. Turn the span screw to set the minimum output pressure. It may

be necessary to repeat steps above until both end points are at desired

values.

Split Range

When calibrated to operate in the split range mode, a full input signal (i.e.

4-20 mA) will operate the unit at one half the normal output span (i.e. 3-

9 psig, 9-15 psig). Setting the unit to operate in the split range mode is

accomplished by positioning internal electrical switches. Disconnect

input signal and supply pressure. Take off the top cover of the unit by

removing the four screws.

Position switches as illustrated in figure 5. Replace cover. After setting

switches, refer to the appropriate calibration procedure (Direct Acting or

Reverse Acting) to get to desired output range (i.e. 3-9 psig, 9-15 psig).

MAINTENANCE

Cleaning

If clean, dry air is not used the orifice can become blocked. To clean, first

turn off supply air, then remove the screw located under the zero

adjustment. Unplug the orifice by using a wire that has a smaller

diameter than 0.012˝ (0.30mm). Use compressed air to blow out any

loose particles inside the orifice screw assembly.

Precautions

The bonnet should be removed only if a different operation mode is

desired which requires a change in circuit board switch settings. In this

case, precautions are necessary.

Never handle circuit board unless properly grounded to prevent ESD

(Electro-static Discharge).

If ESD grounding equipment is not available, hold the 2800 by its

castings and adjust switches using a non-conductive device such as a

pencil or a small rubber handled screwdriver.

Never remove circuit board for any reason. This will shift other

components and possibly damage the pressure sensor, both cases

resulting in malfunction.

Use caution when replacing bonnet. If any resistance is felt, remove

bonnet and determine the interference. Typically it will be the strain relief

grommet on the wires. The grommet should be oriented so it sits beside

the switches.

Clean and dry air should be used with the 2800. Foreign matter in the

supply line can clog the orifice openings. (.013˝ for a 3-15 psig unit,

smaller for higher range unit.) Foreign matter can also collect on the

actuator causing erratic operation. Moisture in the supply line can

damage circuit board components.

The electrical specifications as outlined in these instructions must be

complied to. If more than one 2800 unit is driven by the same PLC, there

must be a minimum of 9.5 VDC available to each unit.

If difficulty is experienced during calibration or if turning the zero or span

screw has no effect on the unit, a resetting technique can be taken. Turn

both the zero and span screw a minimum of 30 revolutions in one

direction. Then turn both screws exactly 15 revolutions in the opposite

direction. This procedure will put the potentiometers at their midpoint of

effective adjustability. Next, calibrate to desired settings starting with the

zero screw.

Reverse Acting Mode: For reverse acting units, the zero adjustment

refers to the minimum electrical signal and maximum output pressure.

The span refers to the maximum signal and the minimum output

pressure. For calibration in reverse mode the resetting technique can be

taken if necessary and calibration should always begin with the zero

screw.

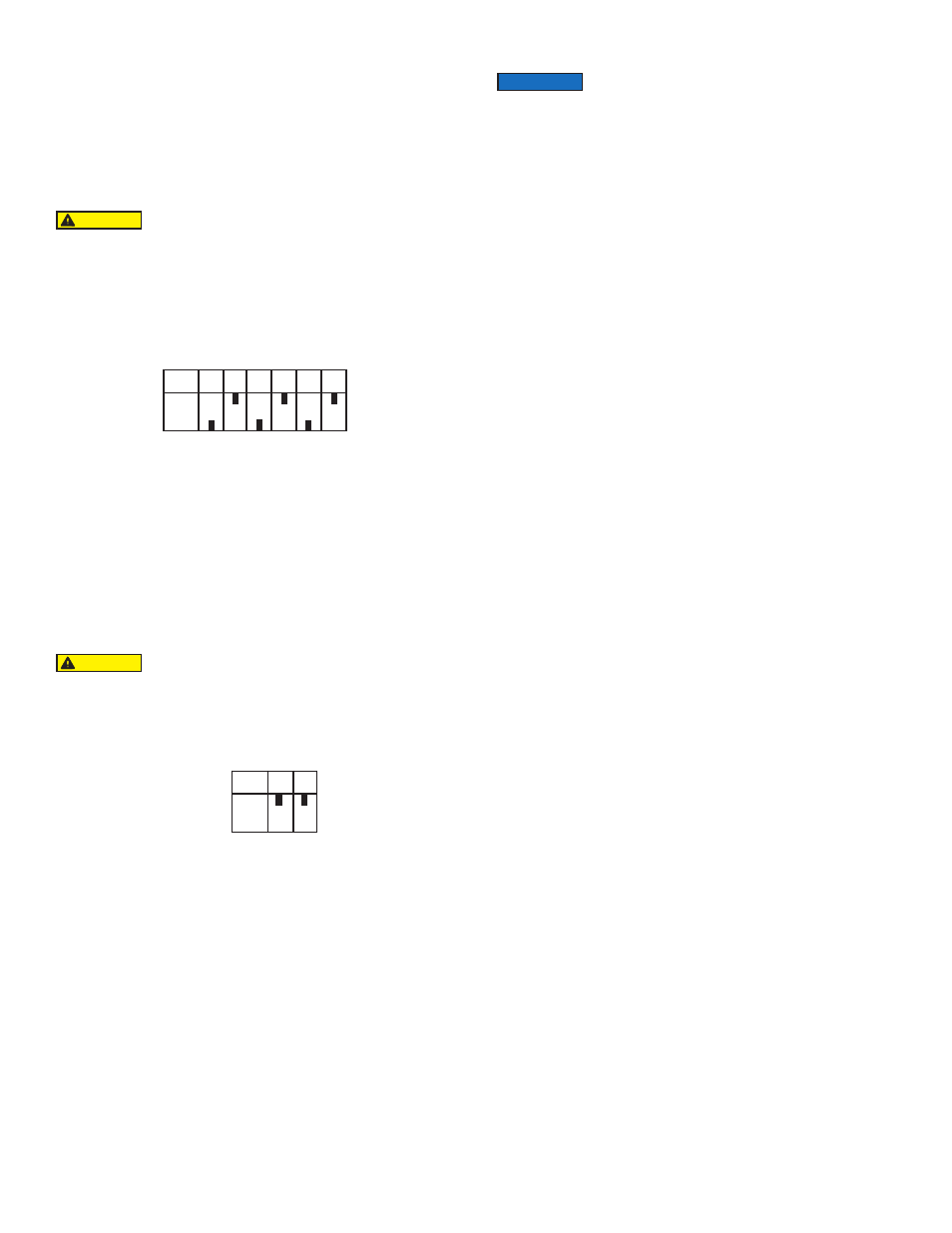

Figure 4

Position of Switches for Reverse Acting Operation

Note: Switches not shown match Direct Acting Setting

(see Figure 3)

Figure 5

Position of Switches for Split Range Operation

Note: Switches not shown match Direct Acting Settings

(see Figure 3)

Switch

3

4

5

6

7

10

ON

OFF

Switch

1

2

ON

OFF

Signal

4-20 mA

Do not reverse the input leads. Avoid touching circuit board.

Shorting possible.

CAUTION

Avoid touching circuit board. Shorting possible.

CAUTION

Under normal circumstances, no maintenance should be

required.

NOTICE