Dwyer DSS User Manual

Page 3

WIRING

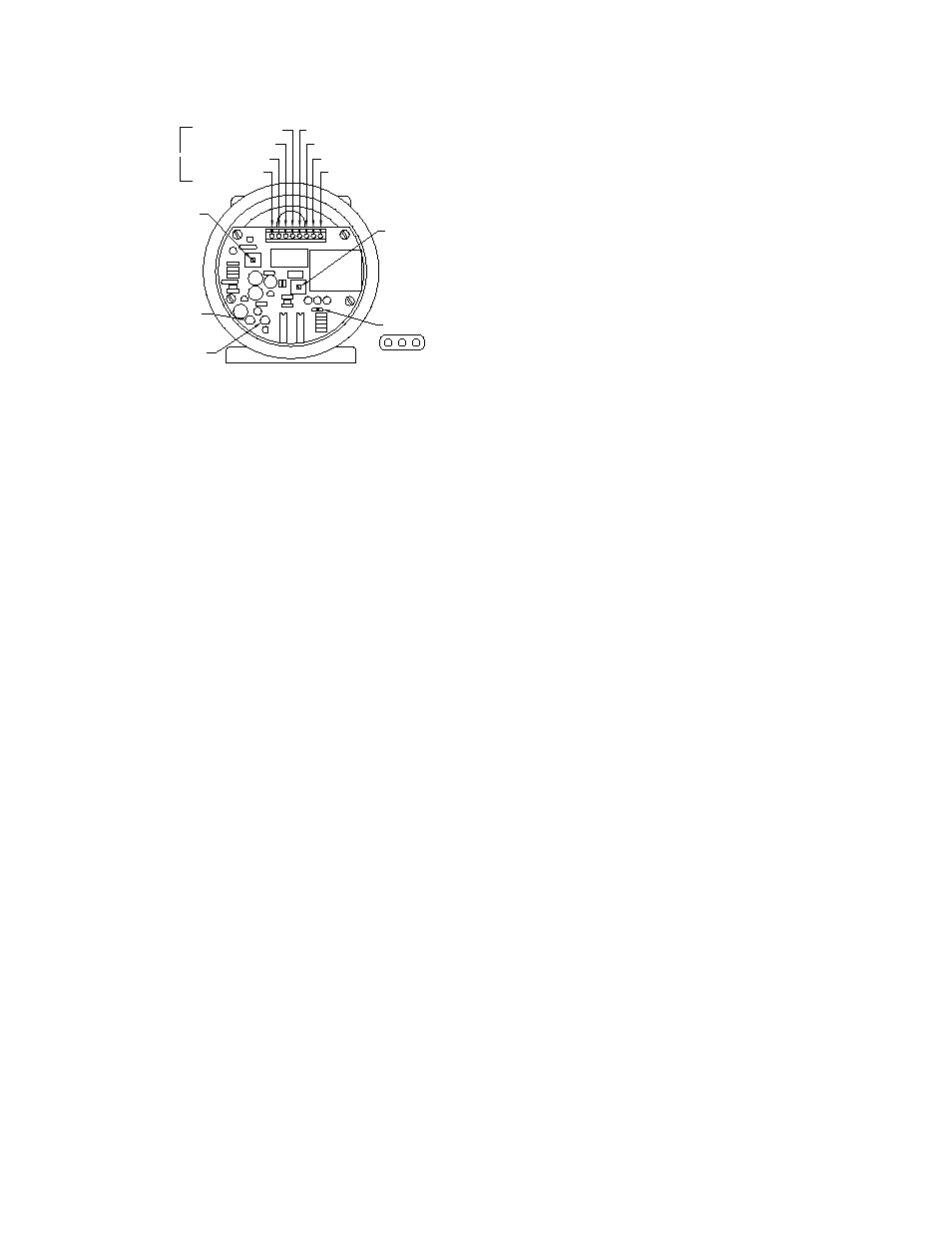

FIGURE 4: Electronics View

Remove end cap to expose terminals and pick-up speed adjustment

screw. Wire input power from source to terminals L1 & L2. Be certain to

use the provided ground screw. The output of the Series DSS is a DPDT

relay. There are two sets of output contacts. Each set includes normally

open, normally closed and common. As a result, the unit can be used to

control two separate circuits such as a motor starter and a signal light.

CONDUIT INSTALLATION:

Use only hubs of suitable sizes that are UL/CSA approved for WATER-

TIGHT use. Install per the hub manufacturer’s instructions. Be sure the

location selected will provide adequate wire bending space.

SIGNAL SET POINT

FOR USE AS AN UNDER-SPEED SWITCH:

Select the speed range required by changing the switch to LOW for 0.1

to 10 RPM, MEDIUM for 1 to 100 RPM and HIGH for 10 to 1000 RPM.

Turn the set point potentiometer to the counter-clockwise stop. With

motion present on the input shaft and at normal operating RPM, the yel-

low LED should blink. The green LED should turn on indicating that the

output relay is energized. Slowly turn the set point adjustment screw

clockwise until the output relay de-energizes. (A “click” will occur at this

point.) Back up until the output relay energizes. Thus, when speed drops

below the set point, the green LED should turn off indicating that the out-

put relay is de-energized. If the normal operating speed of the input shaft

exceeds 10 RPM for the LOW, 100 RPM for the MEDIUM or 1000 RPM

for the HIGH, the unit should be adjusted as follows. Turn the set point

adjustment screw clockwise until it reaches the stop. When the speed

drops below 10 RPM for the HIGH, the relay will energize.

NOTE: Typically, the motor contact is wired in series with one of the NO

output contacts and an alarm is wired with one of the NC output contacts.

FOR USE AS AN OVER-SPEED SWITCH:

Select the speed range required by changing the switch to LOW for 0.1

to 10 RPM, MEDIUM for 1 to 100 RPM and HIGH for 10 to 1000 RPM.

Turn the set point potentiometer to the counter-clockwise stop. With

motion present on the input shaft and at normal operating RPM, the yel-

low LED should turn on indicating that the output relay is energized.

Slowly turn the set point adjustment screw clockwise until the output

relay de-energizes and the green LED turns off. (A “click will occur at this

point.) with the potentiometer on that setting, if the speed increases the

output relay will energize.

NOTE: Typically, the motor contact is wired in series with one of the NO

output contacts and an alarm is wired with one of the NC output contacts.

FOR USE AS A ZERO-SPEED SWITCH:

Select the LOW speed range by changing the switch to LOW for 0.1 to

10 RPM. Turn the set point potentiometer to the counter-clockwise stop.

This will give a set point of 0.1 RPM. Thus, when the speed drops below

0.1 RPM, the output relay will de-energize.

NOTE: Wiring should be the same as for under-speed applications.

Normally open 2

Normally open 1

Normally closed 1

Common 1

Normally closed 2

Common 1

L2

L1

Use only solid conductors

of 14 AWG of smaller

Speed set point

Green LED

Indicates relay energized

Yellow LED

Indicates pulses

Speed Range

L

M

H

Time Delay