Dwyer DSS User Manual

Page 2

OPERATING PRINCIPLE

The Series DSS Motion Switch senses motion by means of a precision

metal disc mounted on the input shaft. This disc generates measurable

light pulses by a series of slots on its periphery, which rotate past an

infrared light source. A photo-electric sensor monitors the series of light

pulses and converts them to digital electronic signals. Solid state circuit-

ry then analyzes the digital signals and activates or de-activates the out-

put relay at the pre-set speed.

Field adjustment of the signal set point is easily accomplished by means

of an adjustment screw on the electronics. For under-speed sensing, the

signal point is set below the normal operating speed of the unit. The out-

put relay will then de-energize if the speed drops below the signal point.

For over-speed sensing, the pick-up point is set above the normal oper-

ating speed. The output relay will energize if the speed exceeds the pick-

up point. Zero-speed sensing can be accomplished by turning the adjust-

ment screw to its minimum setting. The output relay will then de-energize

when the shaft speed of the unit approaches zero.

INSTALLATION

LOCATION & MOUNTING

The Series DSS motion switch can be mounted for operation in any posi-

tion. The surface to which the switch is affixed should be as flat and as

smooth as possible. Bearing brackets and shim plate sets can be used

to mount the unit directly to the pillow block supporting a shaft. On instal-

lations where vibration conditions are not extreme, use 1/4” diameter

machine bolts with lock washers through the four mounting holes in the

base of the switch. (Mounting bolts and lock washers are not furnished

with the switch.) If vibration conditions are extreme, use of a doweling is

recommended through two mounting holes in the switch base. The

switch should be mounted as axially in line, and/or parallel as possible to

the existing shaft, which is to drive the switch. The Series DSS motion

switch can be driven by one of the following means:

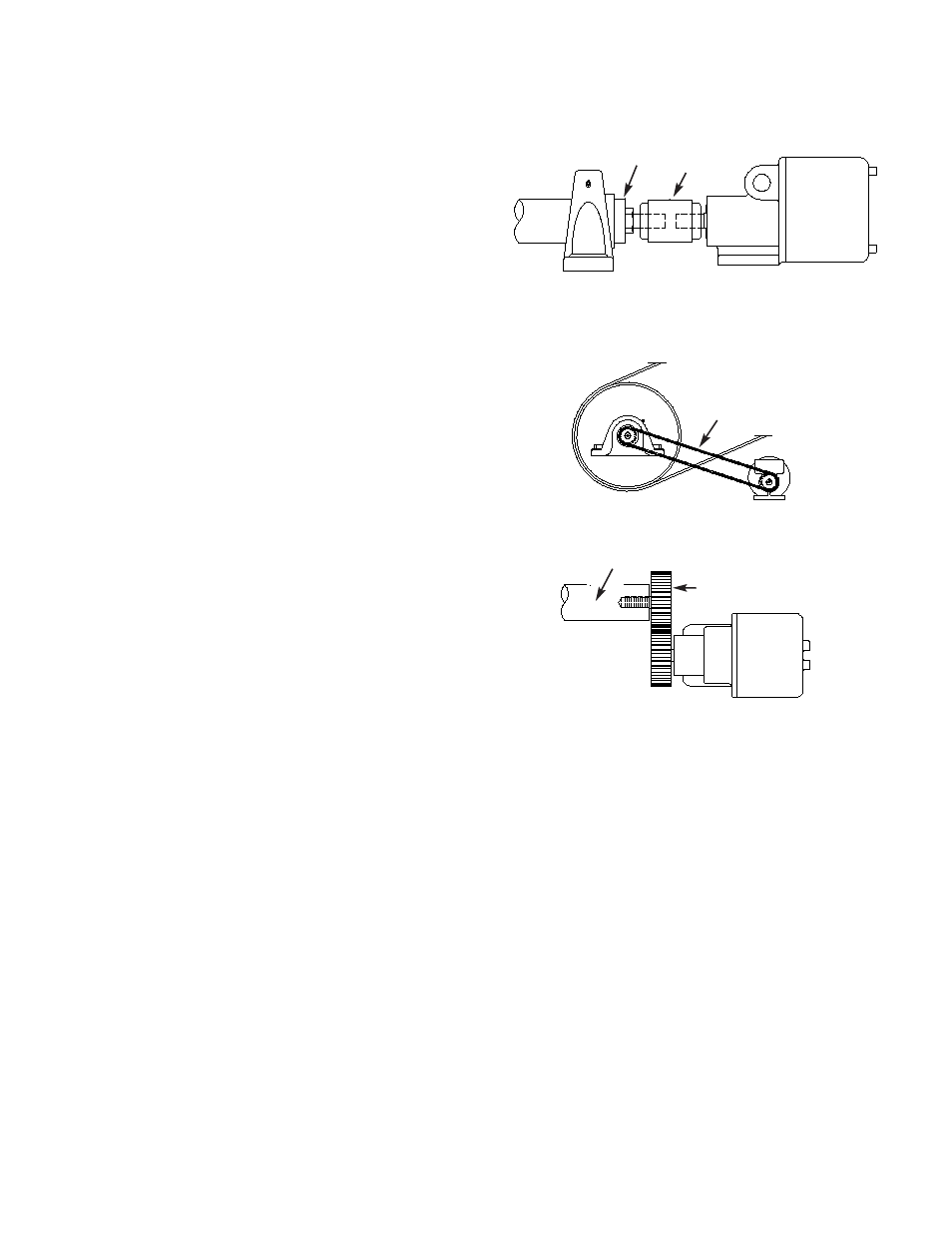

1. FIGURE 1: Suggested Coupling Arrangement, side view. Direct con-

nection through a coupling (preferred means). Note: Switch should be

concentric with the mating shaft. If stub is used, it must be concentric

with the main shaft. If a stub shaft is required, we suggest the use of a

5/8” stub shaft. Use with a split or flexible type coupling.

2. FIGURE 2: Cog Belt Drive (timing) or Roller Chain Drive: A V-Belt drive

is not as desirable because of possible slippage.

3. FIGURE 3: Suggested Spur Gear Arrangement (top view)

Note: Switch should be concentric with

t

The model CMS motion switch can be driven by one of the following

m

If

a stub shaft is required, we suggest the use of a 5/8” stub shaft. Use with a

s

Wire input

p

Customer’s shaft with

concentric stub shaft

Flexible coupling

Cog belt (timing) or

roller chain drive

Customer’s shaft with

concentric stub shaft

Spur gears