Dwyer CBAS User Manual

Page 3

INSTALLATION

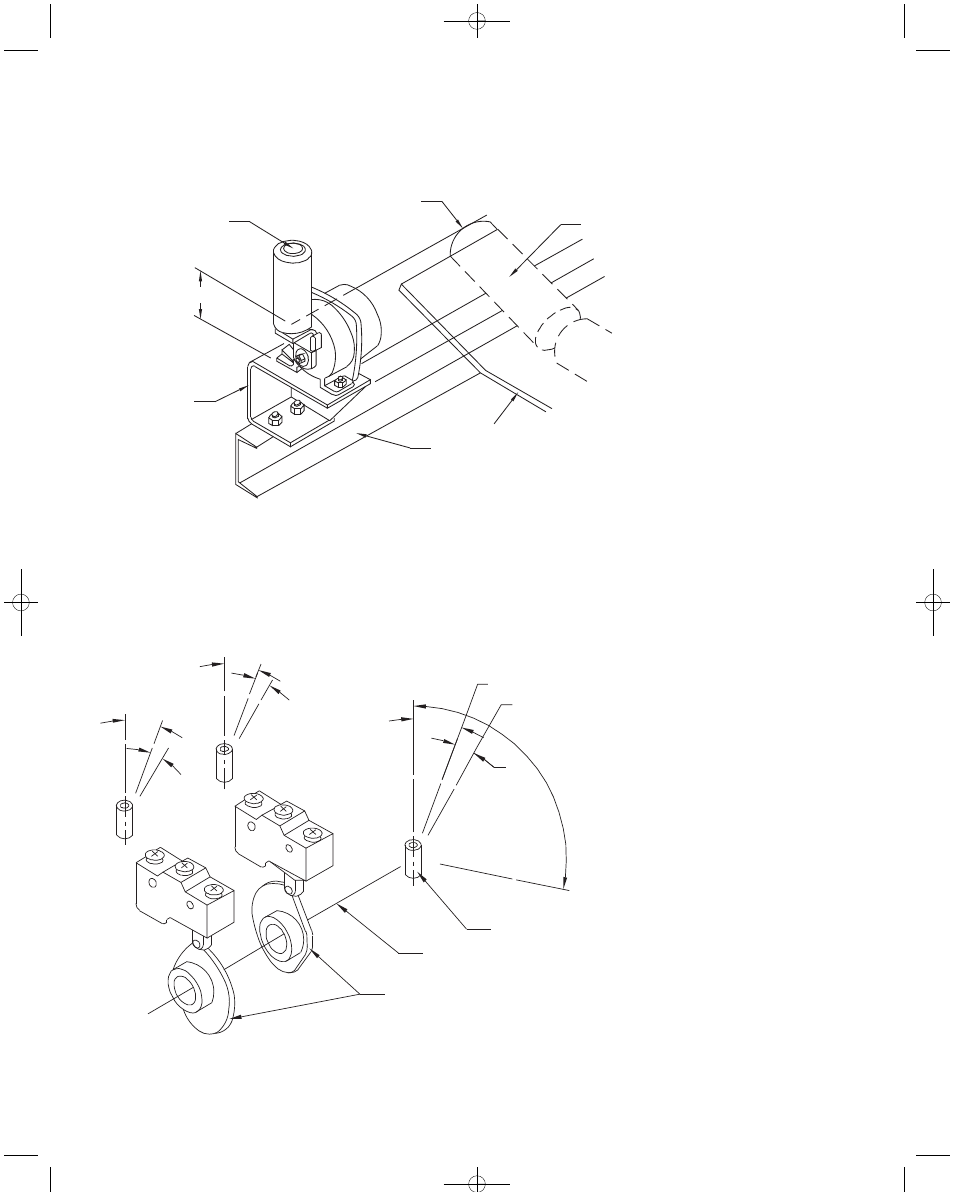

The mounting base should be fitted so that the CBAS touch roller

is 1-3 inches from the outside edge of the conveyor belt. The top

of the idler should be aligned 6.25” from the base of the CBAS.

A typical installations is shown in Fig. 2.

Wiring

The Belt Alignment Switch has 2 SPDT relays that can be

accessed by removing the cover. The independent relays can be

used to control two separate circuits or allow a signal when there

is a slight belt shift and a server belt shift.

TOUCH ROLLER

6.25˝

MOUNTING BASE

CONVEYOR BELT

FRAME OF BELT CONVEYOR

IDLER

TOP OF IDLER

CAM

SHAFT

TOUCH ROLLER

TOUCH ROLLER

MAXIMUM ANGLE

MICROSWITCH OPERATING POSITION

MICROSWITCH OPERATING POSITION

OPEN

20°

OPEN

CLOSED

CLOSED

35°

Fig. 2 Example of Installation of CBAS

Fig. 3 Micro-switch Operating Positions

PC-CBAS:TEMPLATE 3/3/11 3:08 PM Page 3

- DPMX (2 pages)

- DPMP-4 (2 pages)

- DPMP-5 (2 pages)

- DPML-4 (2 pages)

- DPML-5 (2 pages)

- DPMW (2 pages)

- MPM (36 pages)

- SPPM-HSG (1 page)

- SPPM (4 pages)

- SPPM-C (4 pages)

- A-SPPM-TC (2 pages)

- ULB (18 pages)

- CRF2 (4 pages)

- CLT (2 pages)

- PBLT2 (1 page)

- PBLTX (4 pages)

- SBLT2 (1 page)

- SBLTX (4 pages)

- MBLT (2 pages)

- FBLT (2 pages)

- ULT (8 pages)

- UTC (20 pages)

- ULTM (20 pages)

- ULSL (30 pages)

- 1500 (16 pages)

- 2600 (52 pages)

- 2500 (16 pages)

- 16A (1 page)

- 16A (44 pages)

- 1600 (8 pages)

- 1600 (36 pages)

- 8600 (40 pages)

- 32B (32 pages)

- 8C (6 pages)

- SCZ10 (20 pages)

- 8C (24 pages)

- 32A (36 pages)

- 32DZ (40 pages)

- SCD (10 pages)

- SCD-PS (2 pages)

- SCD-8 (2 pages)

- SCD-LED (2 pages)

- 650 (2 pages)

- 651 (2 pages)

- 659RTD (2 pages)