Dwyer DCT1000DC User Manual

Page 8

Still need help? Please feel free to contact one of our customer service representatives or visit us on the web at www.dwyer-inst.com. Thank

you for choosing Dwyer Instruments, Inc.

Printed U.S.A. 10/10

4.0 Glossary of Terms

• Run Mode: The term used when the timer board is firing the

solenoids.

• Pressure Module: The pressure measurement subsystem that

includes the software and hardware for on-demand cleaning, alarms

and signal retransmission of the process variable (i.e., the differential

pressure across the dust bags).

• Master Controller: The primary timer board that contains all of the

major features, connections for external inputs and power to drive the

DCT1000DC Dust Collector Timer Controller system.

• Power DC Guard: A plastic shield that covers the output triacs and

other line voltage circuitry.

• Demand Cycle Mode: A process in which the run mode is enabled

through the on-board pressure module or an external switch.

• Euro Connector: A “caged” connection used to terminate solenoids,

incoming power, or external switches on the DCT1000DC.

• Continuous Cycle Mode: A time based cycling mode dependent on

solenoid time on/off settings and time set between complete cycles.

• Manual Override: Allows the user to override the DCT1000DC

remotely or from the master controller panel through use of a switch or

a wire jumper.

• Slave Board: A channel expander that is used in conjunction with the

master controller to accommodate additional solenoids on larger dust

collection systems. It can be recognized easily as it does not have the

on-board display panel or the power supply present. A master

controller may also be used as a slave board.

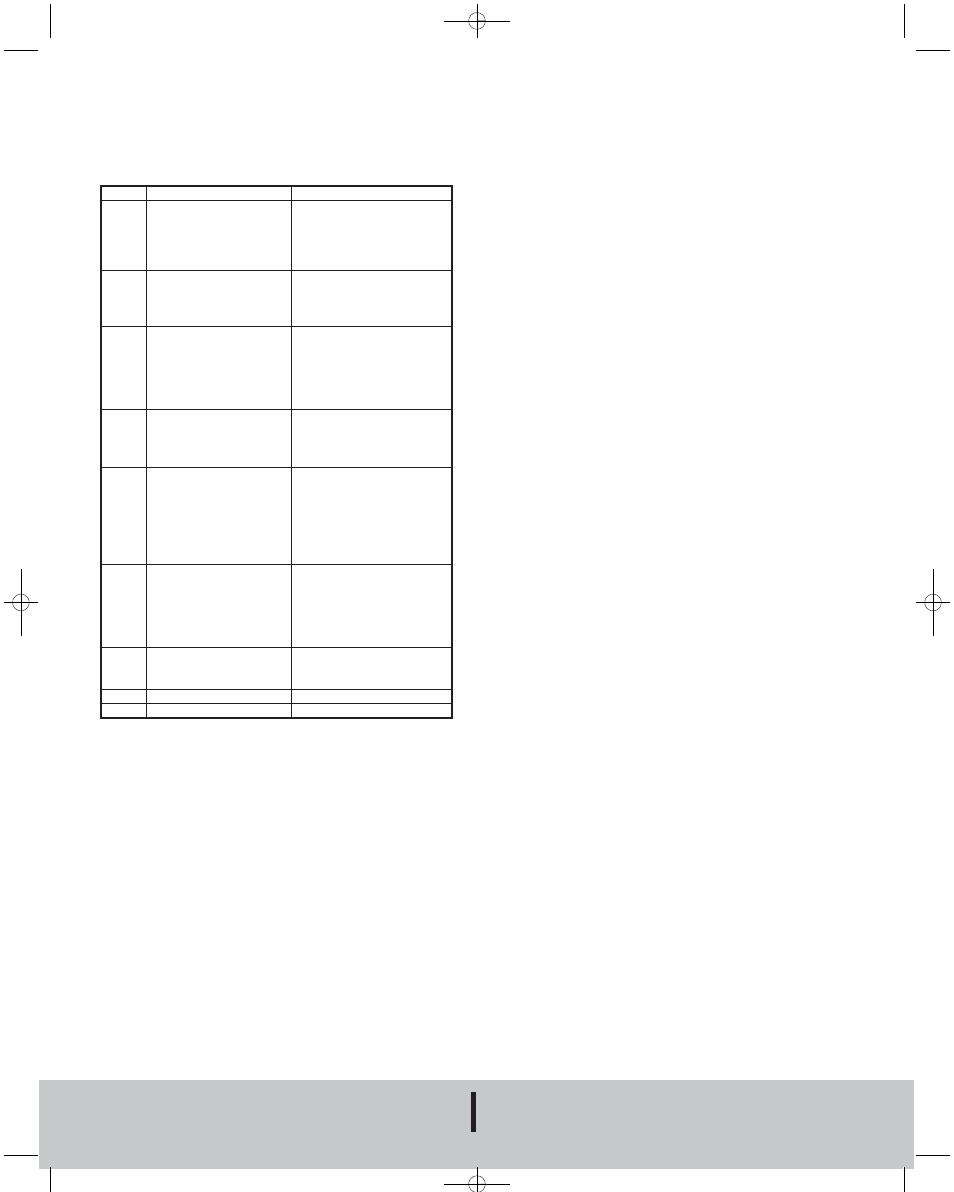

Meaning

This is a “watchdog” reset

that is enabled when the

master controller isn’t able

to cycle through its

operation.

The pressure module has

failed to respond to the

request of the master

controller.

Communication error in the

daisy chain interface. This

will only appear when the

master controller is used in

conjunction with a slave

board.

The master controller has

detected a change in

module configuration or a

fault in one of the modules.

If the fault described in “Err

4” is not corrected, the

master controller will

reconfigure the modules

that are responding

properly and operate at a

degraded condition.

A message error affecting

the software of the master

controller or one of its

modules.

Indicates that one of the

triac drivers are not

functioning.

Internal Error.

Unassigned message code.

Action Required

Make sure all electrical

connections are appropriately

shielded so the master

controller is not disrupted by

noise.

The master controller will try

to recover from the fault. If

unsuccessful, replace the

pressure module.

Make sure the control cable

used in the daisy chain

interface is properly shielded

from noise.

Reinstall all modules in

accordance with the

instructions in the factory IOM.

Reinstall all modules. Contact

factory if the problem persists.

Check the integrity of all

connecting cables used to

drive slave boards for

additional solenoids. Also

check the electrical grounding

of the system installation.

Return to factory for

evaluation and repair.

Contact the factory.

Contact the factory.

Display

Err 1

Err 2

Err 3

Err 4

Err 5

Err 6

Err 7

Err 8

Err 9

3.5 Error Codes

Error codes will be displayed on the three-digit display when certain faults

occur. Most of these indicators are associated with the daisy chain

communication, but certain error codes pertain to single board operation

also. These codes are:

FR# 443123-05 Rev. 3

©Copyright 2010 Dwyer Instruments, Inc.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361 U.S.A.

Phone: 219/879-8000

www.dwyer-inst.com

Fax: 219/872-9057

e-mail: [email protected]

E-97DC:e-97DC 10/5/10 8:27 AM Page 8