Dwyer MVR User Manual

Page 4

- 4 -

Flag Installation

General Notes

Under normal circumstances, it should not be necessary to reposition the flag assembly on your ViewRite. However, if

you find it desirable or necessary to reposition the flag assembly, we strongly recommend that you first mark the dis-

tance from the top of the weldment to the top of the flag assembly. Before securing the flag assembly in a new radial

position, ensure that the distance from the top of the flag assembly to the top of the weldment is the same as the previ-

ously noted dimension. Making a temporary or permanent mark on the weldment can ease the process.

Maintenance

The only maintenance typically required is to ensure that the internal walls of the weldment and the float are free of

foreign matter. This may be accomplished by removing the float assembly from the unit and wiping both the float and

the inside wall of the float chamber or weldment. Any maintenance interval is to be established by the user of the

ViewRite and would depend upon the characteristics of the application. Maintenance could coincide with tank cleaning

or flushing.

Float Installation

Mini ViewRite Float:

To accomplish the removal and subsequent reinstallation of the float assembly, follow the appropriate instructions pro-

vided on page 5 for the ViewRite type and mounting configuration you have selected.

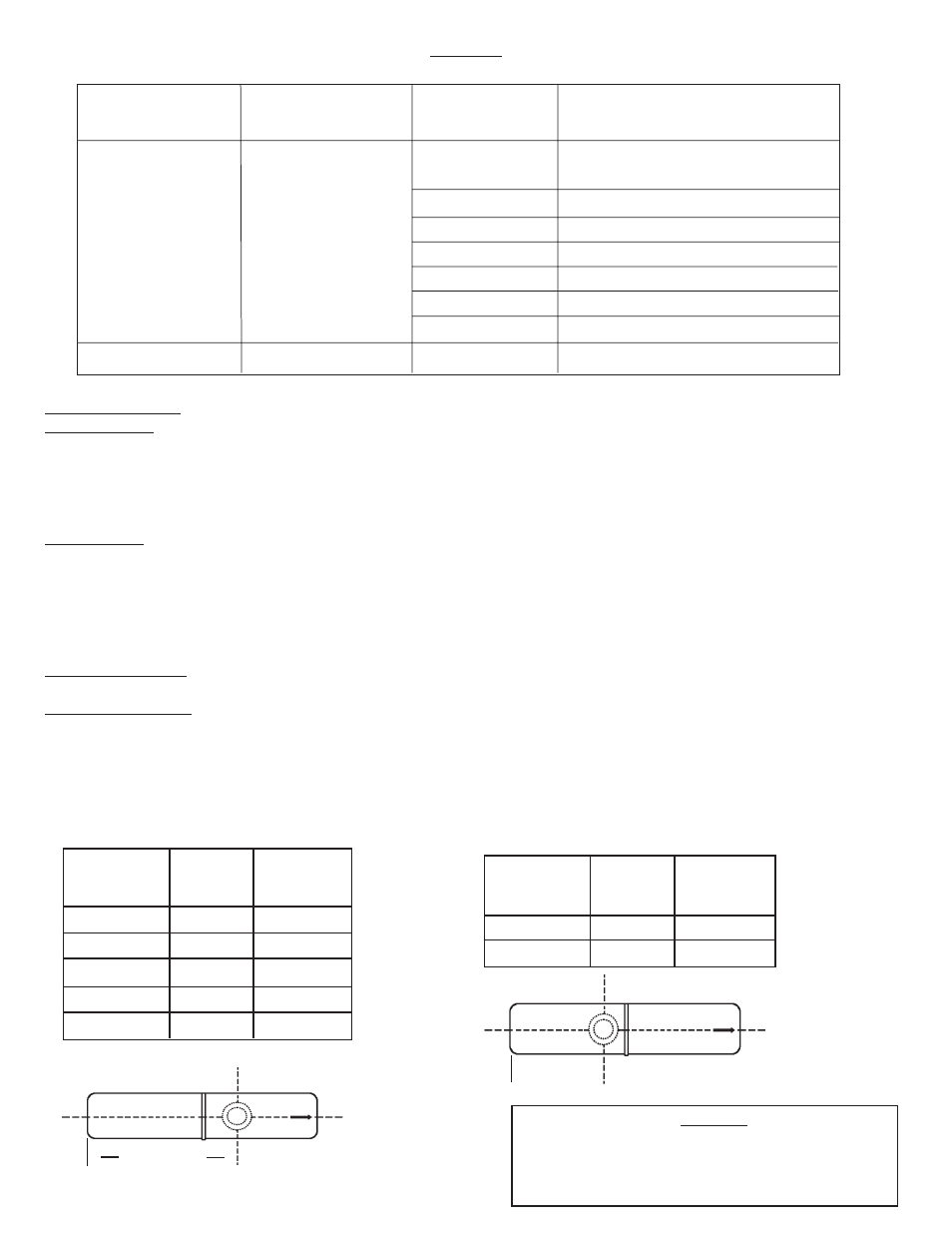

Figure A

(Recommended Torque Values are for Lubricated Threads, Only)

To set magnet position hold the float vertical. A paper clip will attach to the magnet to show its position. Adjust the

magnet position by gently tapping the end of the float.

Indicator Type

Fastener

Description

Nominal

Size

Torque Value

3/8 Inch

1/2 Inch

5/8 Inch

3/4 Inch

7/8 Inch

1 Inch

1-1/8 Inch

Bolt, Nut

Bolt, Nut

Standard Alloy,

Top-Mount Alloy

Mini

30 Lb-Feet

60 Lb-Feet

100 Lb-Feet

150 Lb-Feet

250 Lb-Feet

350 Lb-Feet

70 - 80 Lb.-Inches NTE

(Not to Exceed) 120 Lb.-Inches

5/16 Inch

70 - 80 Lb-Inches

88111

801708

1.9

1.5

2”

2.6875”

Float

Part Number

Liquid

Specific

Gravity

“X”

Dimension

Basic Float Part No. 807200

(Liquid Specific Gravity Range: 1.5 to 3.8)

85206

83453

85208

85209

84158

0.8

0.9

1

1.2

0.85

5”

4.5”

4”

3.312”

4.75”

Float

Part Number

Liquid

Specific

Gravity

“X”

Dimension

Basic Float Part No. 807100

(Liquid Specific Gravity Range: 0.8 to 1.2)

TOP

807100

“X”

Dimension

“X”

Dimension

TOP

807200

Caution

Make sure that the tank is depressurized

and that liquid has been emptied prior to

removal of the float assembly.